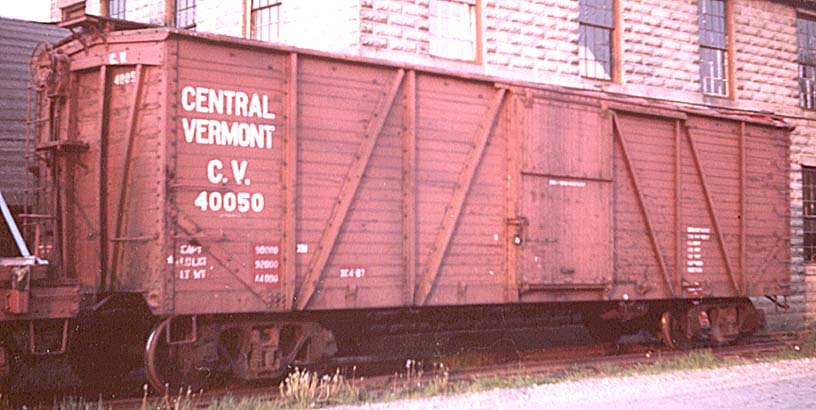

Prototype History: The outside braced single sheathed box car proved to be a significant development in railway freight car technology in North America. Thousands of them saw use on North American railways beginning in the late 19th century through the 1960s. They carried bulk products such as grain and coal. They also carried packaged or bagged lading referred to as clean lading. While most of the outside braced cars were built for general service, some were built specifically to carry machinery and automobiles. For forty years freight trains on the prairies and indeed all across the country consisted of long lines of outside braced boxcars. They could commonly be found at elevators and loading platforms in communities small and large. They dominated railway yard scenes well into the 1940s.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

Road Name History:  "Dimensional Data" here means painted models with printed body specifications and no road/reporting letters/marks or road Name/livery. The data typically consists of internal and external dimensions, capacities, weight information and specific characteristics of freight cars, trailers and containers.

"Dimensional Data" here means painted models with printed body specifications and no road/reporting letters/marks or road Name/livery. The data typically consists of internal and external dimensions, capacities, weight information and specific characteristics of freight cars, trailers and containers.

The Association of American Railroads (AAR) sets standards for the uniform marking of freight cars with regard to car ownership, weight, load capacity, dimensions, and maintenance. In addition, car owners choose to display data relating to various devices and equipment so the cars may be properly used and repaired.

CAPY (nominal capacity) is the intended load-carrying capacity of the car, to the nearest 1000 pounds. This is determined by the structural strength of the car's underframe and the size of the journal bearings of the car's trucks.

LD LMT (load limit) is the maximum weight of lading that can be carried by the car, to the nearest 100 pounds. This is determined by subtracting the weight of the car when empty from the total allowable gross weight given the size of the car's journal bearings. The load limit for a car is usually a bit greater than its capacity; the two figures can be equal, but capacity can never exceed load limit.

LT WT (light, or empty, weight) is the weight of the car when empty. Accompanying the light weight marking is a date indicating when the railroad or owner last verified the car's weight. The letters for this mark are not always reporting marks; sometimes a location code is used. NEW and a date indicates that the weight shown is the car's as-built weight, and that it hasn't been field-checked since.

The Association of American Railroads (AAR) sets standards for the uniform marking of freight cars with regard to car ownership, weight, load capacity, dimensions, and maintenance. In addition, car owners choose to display data relating to various devices and equipment so the cars may be properly used and repaired.

CAPY (nominal capacity) is the intended load-carrying capacity of the car, to the nearest 1000 pounds. This is determined by the structural strength of the car's underframe and the size of the journal bearings of the car's trucks.

LD LMT (load limit) is the maximum weight of lading that can be carried by the car, to the nearest 100 pounds. This is determined by subtracting the weight of the car when empty from the total allowable gross weight given the size of the car's journal bearings. The load limit for a car is usually a bit greater than its capacity; the two figures can be equal, but capacity can never exceed load limit.

LT WT (light, or empty, weight) is the weight of the car when empty. Accompanying the light weight marking is a date indicating when the railroad or owner last verified the car's weight. The letters for this mark are not always reporting marks; sometimes a location code is used. NEW and a date indicates that the weight shown is the car's as-built weight, and that it hasn't been field-checked since.

Brand/Importer Information: Micro-Trains is the brand name used by both Kadee Quality Products and Micro-Trains Line. For a history of the relationship between the brand and the two companies, please consult our Micro-Trains Collector's Guide.

Manufacturer Information:  Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

In October 1990 Kadee separated in two companies, with the newly created Micro-Trains® Line Co. continuing the Z, Nn3, and N Scale product ranges, with Kadee retaining the HO range.

In October 1990 Kadee separated in two companies, with the newly created Micro-Trains® Line Co. continuing the Z, Nn3, and N Scale product ranges, with Kadee retaining the HO range.

Item created by: Lethe on 2015-05-31 17:46:30. Last edited by gdm on 2020-07-21 10:37:00

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.