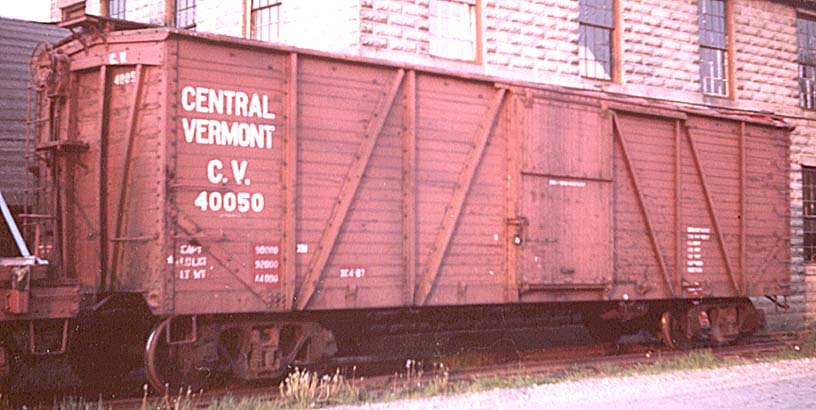

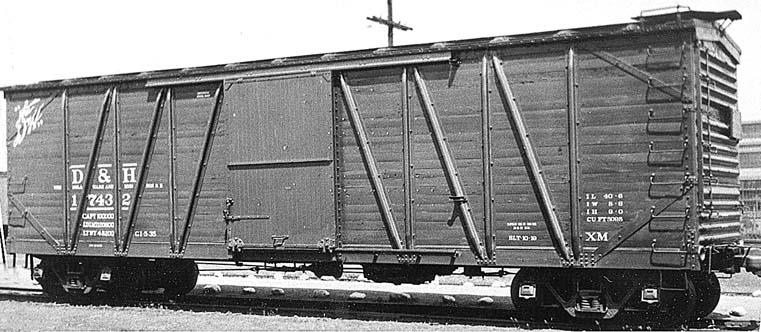

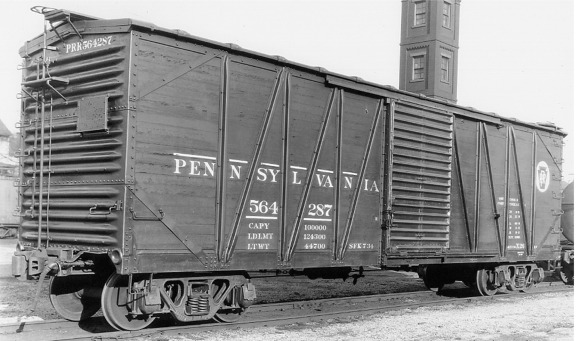

History: The outside braced single sheathed box car proved to be a significant development in railway freight car technology in North America. Thousands of them saw use on North American railways beginning in the late 19th century through the 1960s. They carried bulk products such as grain and coal. They also carried packaged or bagged lading referred to as clean lading. While most of the outside braced cars were built for general service, some were built specifically to carry machinery and automobiles. For forty years freight trains on the prairies and indeed all across the country consisted of long lines of outside braced boxcars. They could commonly be found at elevators and loading platforms in communities small and large. They dominated railway yard scenes well into the 1940s.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

Railroad/Company: This set of items is comprised of more than one name. Please look at the component items for details on the specific roadnames and/or manufacturers.

Item Links: We found: 3 different collections associated with Rail - Rolling Stock (Freight) - 40 Foot Single Wood Sheathed Outside Braced

- Collection N Scale Model Trains: 132 different items.

- Collection Z Scale Trains: 41 different items.

- Collection HO Scale Model Trains: 1 different items.

Item created by: gdm on 2018-03-02 10:14:08. Last edited by gdm on 2018-04-03 17:47:12

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.