History: This design had a life span that is truly enormous. The last cars of this design were built in the 1960's -- three decades after the first cars were built for Santa Fe. Quite a few of these cars are still in service. Because you have to stand on the roof in order to open the hatches, these cars were immune from the "No Roof Walk" rule of 1964, but a number would be scrapped when friction bearing trucks were outlawed. Amazingly, some cars are now being retired because they have hit the Federal Railroad Administration's 50 year rule!

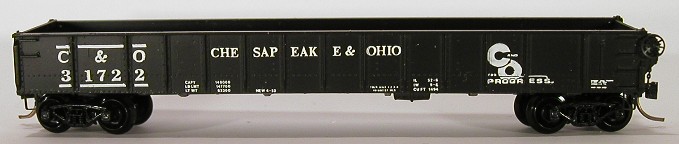

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Railroad/Company: ACF Industries LLC originally known as The American Car and Foundry Company and was formed in 1899. In 1955 ACF Industries, Incorporated became the new name for The American Car and Foundry. Over the years railcar manufacturing and leasing were the major forces in ACF's economic growth and stability. ACF has weathered many changes and is still committed to the manufacture of new railcar and railcar parts and sub-assemblies. ACF Industries LLC became a successor to ACF Industries, Incorporated on May 1, 2003.

ACF Industries LLC is a leader in the manufacture and fabrication of specialty railcar parts and miscellaneous steel products. While the Company's primary purpose is to compliment the new car and repair car market, it also provides manufacturing support to other manufacturers of steel products.

ACF Industries LLC is headquartered in St. Charles, Missouri and our manufacturing facility is located in Milton, Pennsylvania.

From the company website.

ACF Industries LLC is a leader in the manufacture and fabrication of specialty railcar parts and miscellaneous steel products. While the Company's primary purpose is to compliment the new car and repair car market, it also provides manufacturing support to other manufacturers of steel products.

ACF Industries LLC is headquartered in St. Charles, Missouri and our manufacturing facility is located in Milton, Pennsylvania.

From the company website.

Item Links: We found: 1 different collections associated with Rail - Rolling Stock (Freight) - 2-Bay ACF 36 Foot

- Collection N Scale Model Trains: 251 different items.

Item created by: gdm on 2018-01-22 16:01:09. Last edited by gdm on 2019-07-02 14:54:28

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.