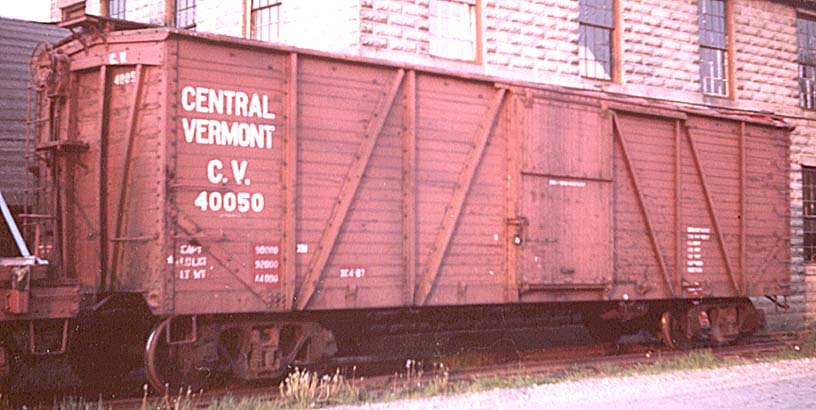

Model Information: Single Wood Sheath outside braced 40 foot boxcar with a single sliding door.

Prototype History: The outside braced single sheathed box car proved to be a significant development in railway freight car technology in North America. Thousands of them saw use on North American railways beginning in the late 19th century through the 1960s. They carried bulk products such as grain and coal. They also carried packaged or bagged lading referred to as clean lading. While most of the outside braced cars were built for general service, some were built specifically to carry machinery and automobiles. For forty years freight trains on the prairies and indeed all across the country consisted of long lines of outside braced boxcars. They could commonly be found at elevators and loading platforms in communities small and large. They dominated railway yard scenes well into the 1940s.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

Road Name History:  The P&N was the result of the 1914 merger of The Piedmont Traction Company and the Greenville Spartanburg & Anderson Railway. Both predecessors were built by a pair of Utility moguls, most notably James B. Duke. P&N ran two disconnected lines, one in South Carolina and the other in North Carolina. The former ran from Anderson through Greenville to Spartanburg with a branch to Greenwood. The North Carolina operation ran from Gastonia to Charlotte but a long branch was built from this line to a Duke power plant in Terrell in 1965. The P&N was electrified with 1500 volt DC with the expectation of running steam road size freights along with interurban cars. The 1950s brought big changes to P&N. The first diesel arrived in 1950 and in 1951 the South Carolina operation was fully dieselized and passenger service was ended. In North Carolina, the wire started to come down in 1954 with the exception of a short segment in Charlotte that lasted another four years. For a number of years, P&N shared a management team with the Durham & Southern which was also owned by Duke. In 1969, Duke sold the P&N to Seaboard Coast Line who merged the company that year.

The P&N was the result of the 1914 merger of The Piedmont Traction Company and the Greenville Spartanburg & Anderson Railway. Both predecessors were built by a pair of Utility moguls, most notably James B. Duke. P&N ran two disconnected lines, one in South Carolina and the other in North Carolina. The former ran from Anderson through Greenville to Spartanburg with a branch to Greenwood. The North Carolina operation ran from Gastonia to Charlotte but a long branch was built from this line to a Duke power plant in Terrell in 1965. The P&N was electrified with 1500 volt DC with the expectation of running steam road size freights along with interurban cars. The 1950s brought big changes to P&N. The first diesel arrived in 1950 and in 1951 the South Carolina operation was fully dieselized and passenger service was ended. In North Carolina, the wire started to come down in 1954 with the exception of a short segment in Charlotte that lasted another four years. For a number of years, P&N shared a management team with the Durham & Southern which was also owned by Duke. In 1969, Duke sold the P&N to Seaboard Coast Line who merged the company that year.

Brand/Importer Information: Micro-Trains is the brand name used by both Kadee Quality Products and Micro-Trains Line. For a history of the relationship between the brand and the two companies, please consult our Micro-Trains Collector's Guide.

Manufacturer Information:  Micro-Trains Line split off from Kadee Quality Products in 1990. Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Micro-Trains Line split off from Kadee Quality Products in 1990. Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Please consult our Micro-Trains Collector's Guide

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Please consult our Micro-Trains Collector's Guide

Item created by: gdm on 2017-03-08 15:06:41. Last edited by Lethe on 2020-05-07 00:00:00

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.