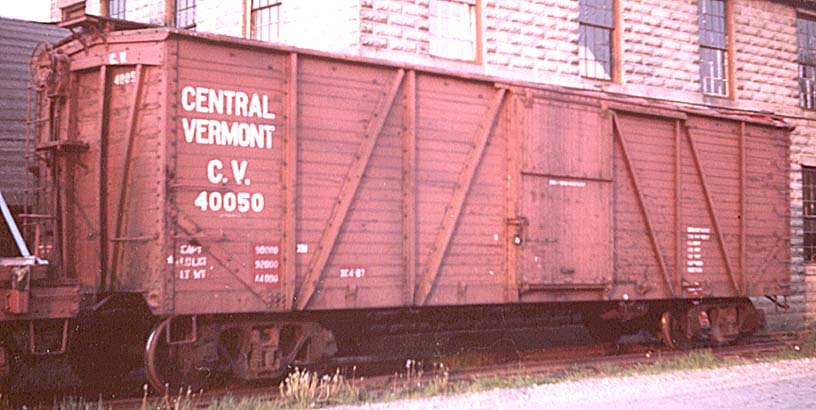

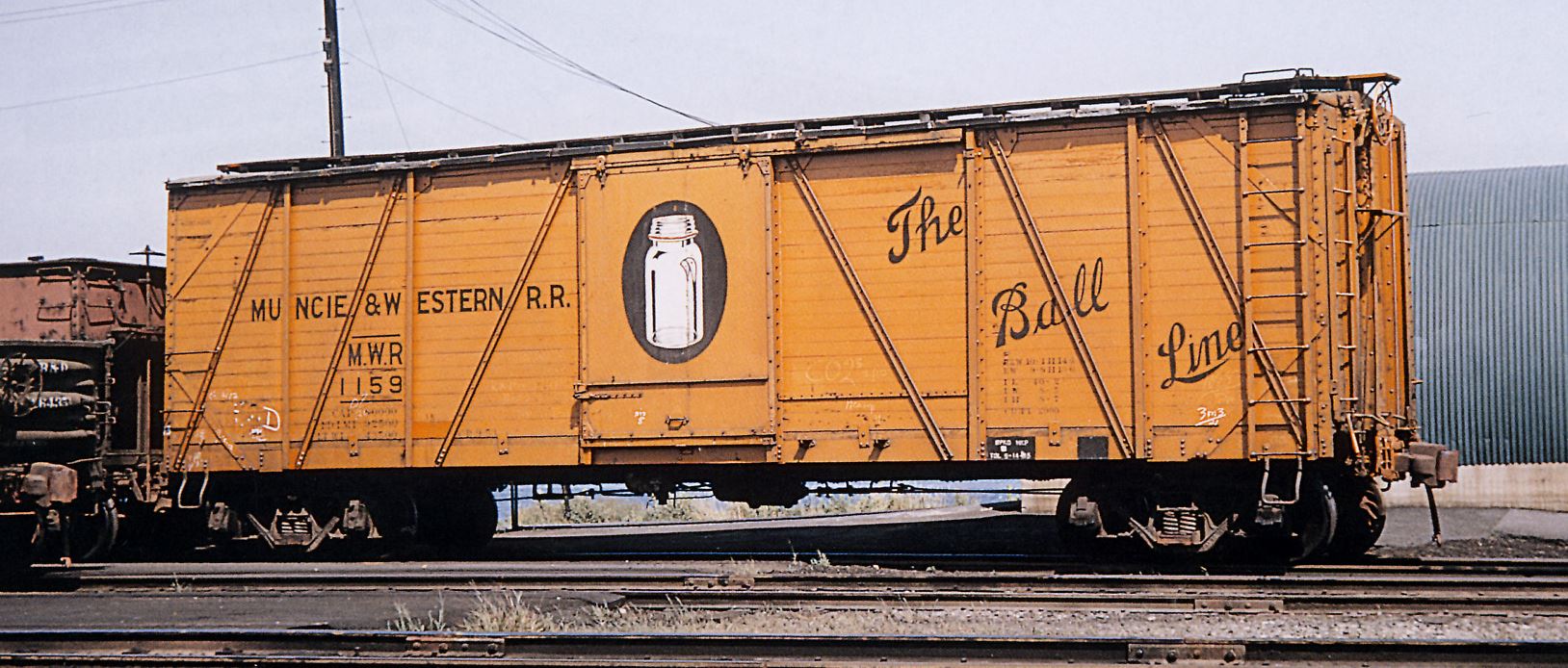

Specific Item Information: Outside braces slant towards the door -- ACF designed "Howe Truss"

Model Information: This model was originally developed by Mehano for Atlas to replace the Atlas 40' composite boxcar tooling. It is a knockoff of the Roco tooling. It is so similar that I suspect Mehano obtained the rights to the Roco tooling with Atlas' help. It has also been produced for MRC, Life-Like and Model Power. It has been through at least one minor revision to improve the molded detail on the shell. It carries Nickel-Silver plated deep flange wheels and a Rapido coupler.

Prototype History: The outside braced single sheathed box car proved to be a significant development in railway freight car technology in North America. Thousands of them saw use on North American railways beginning in the late 19th century through the 1960s. They carried bulk products such as grain and coal. They also carried packaged or bagged lading referred to as clean lading. While most of the outside braced cars were built for general service, some were built specifically to carry machinery and automobiles. For forty years freight trains on the prairies and indeed all across the country consisted of long lines of outside braced boxcars. They could commonly be found at elevators and loading platforms in communities small and large. They dominated railway yard scenes well into the 1940s.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

The use of steel for the under frame (center and side sills), side and end frames initiated a new form of railway freight car building technology. Steel center sills and other under sill framing gave the cars the strength necessary to withstand the stress of longer and faster trains as well as the considerable stress involved in the contact necessary to activate closure of the knuckle coupler while being made up into trains in rail yards or from being picked up from local sidings along the line. The steel frame and the single wood side sheath minimized the weight of the car. This type of car design led to easy construction and repair. Its initial construction cost was low. The design provided secure joints between sides, ends and floors which prevented grain leakage.

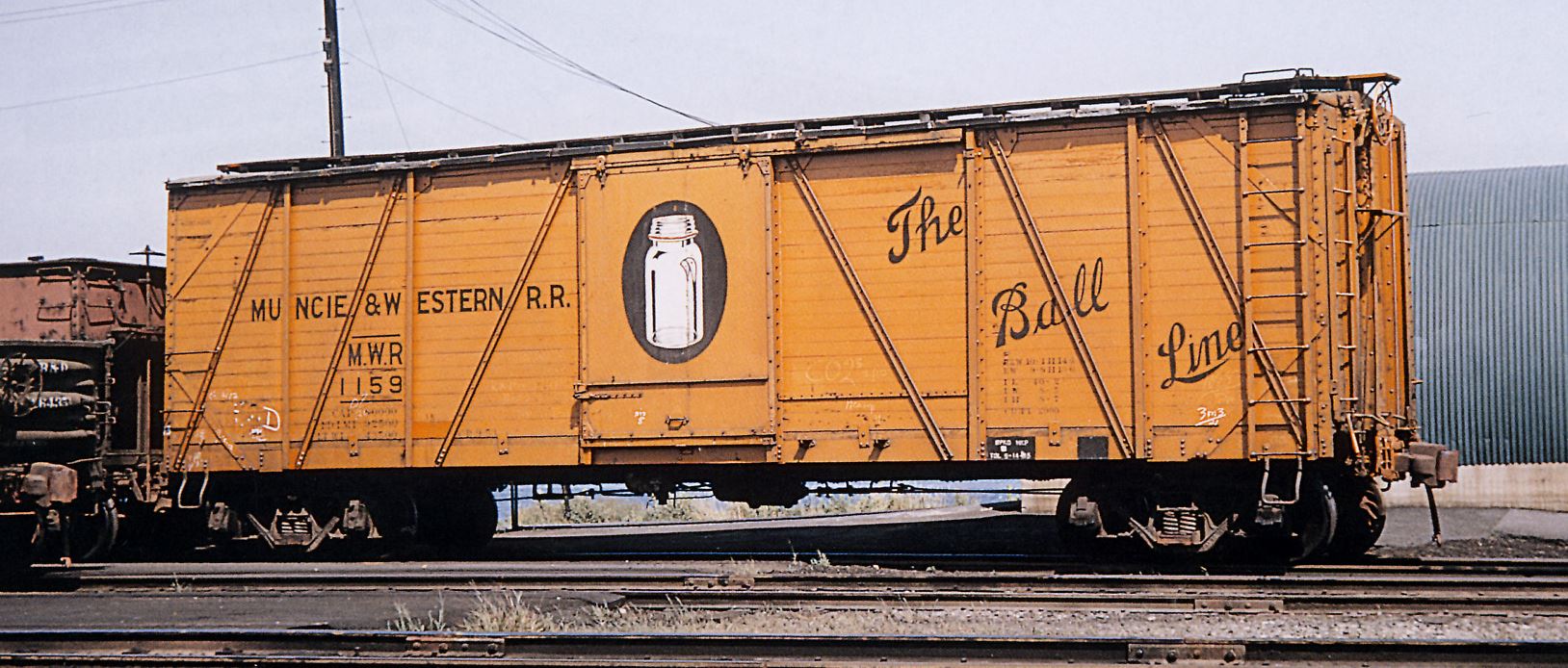

Road Name History:  The railroad of Muncie and Western Railroad Company, was incorporated in Indiana, on May 12, 1902. It was a single-track, standard-gauge, steam railroad, located in the city of Muncie, Ind. It is the shortest railroad in the USA.

The railroad of Muncie and Western Railroad Company, was incorporated in Indiana, on May 12, 1902. It was a single-track, standard-gauge, steam railroad, located in the city of Muncie, Ind. It is the shortest railroad in the USA.

Nicknamed the “Ball Line” but legally incorporated as the Muncie and Western Railroad, the railroad was operated in the confines of the Ball Corporation’s plant on Muncie’s south side. It was busiest in the days when boxes of Ball glass (Mason) jars home-canned foods filled the family pantry.

The property consists of a belt railroad connecting various railroads with the industries of Muncie. The owned main line is 0.749 of a mile in length. The carrier also owns yard and side tracks totaling 3.181 miles. Its road thus embraces 3.930 miles of all tracks owned.

Nicknamed the “Ball Line” but legally incorporated as the Muncie and Western Railroad, the railroad was operated in the confines of the Ball Corporation’s plant on Muncie’s south side. It was busiest in the days when boxes of Ball glass (Mason) jars home-canned foods filled the family pantry.

The property consists of a belt railroad connecting various railroads with the industries of Muncie. The owned main line is 0.749 of a mile in length. The carrier also owns yard and side tracks totaling 3.181 miles. Its road thus embraces 3.930 miles of all tracks owned.

Brand/Importer Information:  Tempo was a brand from MehanoTehnika, from Izola, Yugoslavia (now Slovenia), that was used in the 1960s for HO and N scale models.

Tempo was a brand from MehanoTehnika, from Izola, Yugoslavia (now Slovenia), that was used in the 1960s for HO and N scale models.

MehanoTehnika was also supplying its models to several other brands such as Atlas, AHM, Life-Like and Model Power.

MehanoTehnika was also supplying its models to several other brands such as Atlas, AHM, Life-Like and Model Power.

Manufacturer Information: Mehano is a Slovenian toy manufacturer located in Izola, Slovenija. The company was founded as Mehanotehnika and was producing toys starting in June 1953. They first exhibited at the Nuerenberg Toy Fair in 1959. Mehano produced a number of different locomotives and rolling stock models for the North American market in the 1960s and 1970s. Companies such as Atlas and Life-Like imported a huge variety of their products. Generally they can easily be recognized as they are stamped "Yugosolavia" on the underframe. The company was formally renamed "Mehano" in 1990. Izola today is part of the country of Slovenia since the breakup of Yugoslavia.

Mehano filed for bankruptcy in 2008, but still continued to exist and operate. Since 2012, Mehano products are distributed by Lemke.

Mehano filed for bankruptcy in 2008, but still continued to exist and operate. Since 2012, Mehano products are distributed by Lemke.

Item created by: Alain LM on 2023-05-05 13:19:47. Last edited by Alain LM on 2023-05-05 13:19:48

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.