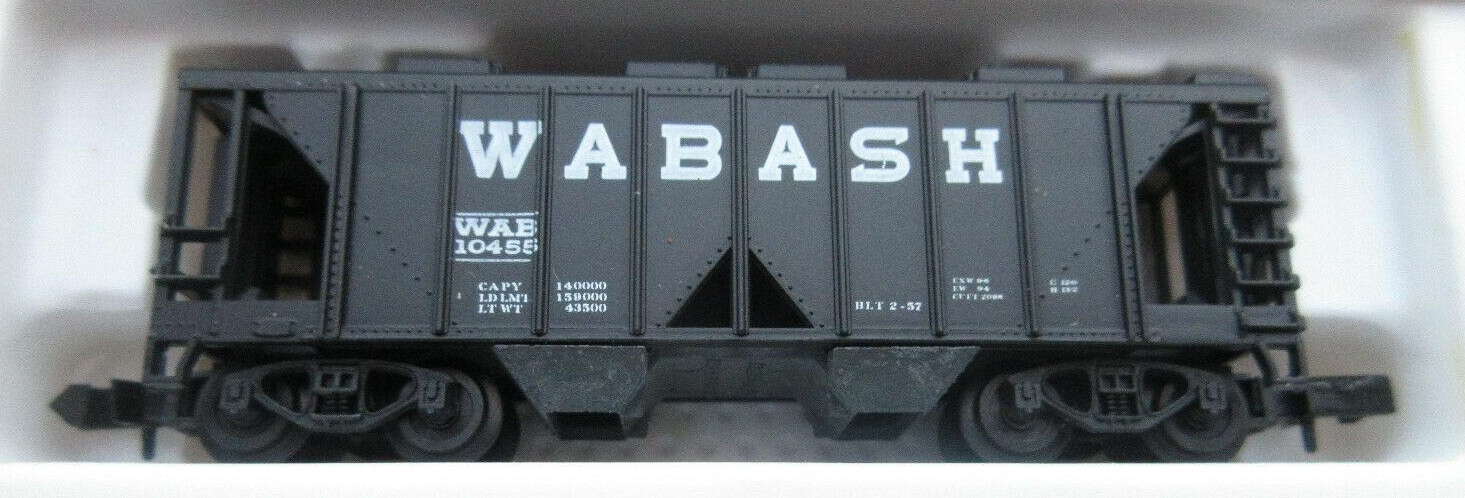

Model Information: This model was introduced by Arnold in the 1980s. It features a die-cast underframe and a plastic body. The trucks are interesting as they are held to the underframe by some kind of quasi-rivet mechanism. Good luck swapping them for MTL trucks.... The wheels are injection molded plastic but with a steel axle. The flanges on these wheels are definitely deep. The hopper bays on the sample I got my hands on look like they are missing their hatches. I don't know if this is by design or if there was a detail part that came off. Nice printing and rivet detail on the body for the 1980s but nothing special for the 2000's. Walthers imported most (if not all) of models to the United States from Germany where they were produced.

Prototype History: This design had a life span that is truly enormous. The last cars of this design were built in the 1960's -- three decades after the first cars were built for Santa Fe. Quite a few of these cars are still in service. Because you have to stand on the roof in order to open the hatches, these cars were immune from the "No Roof Walk" rule of 1964, but a number would be scrapped when friction bearing trucks were outlawed. Amazingly, some cars are now being retired because they have hit the Federal Railroad Administration's 50 year rule!

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Road Name History: Wabash was the product of an 1889 restructuring (under the leadership of Jay Gould) of several railroads centered around the Wabash St. Louis & Pacific. Wabash was unusual in that it evenly straddled the border between “eastern railroads” and railroads west of the Chicago-St.Louis-Memphis-New Orleans border. In the west, Wabash connected Kansas City, Omaha and Des Moines. Heading east from those points, Wabash reached St. Louis, Decatur, and Chicago. Then, clearly in the eastern territory, Wabash reached Fort Wayne, Detroit, Toledo and finally Buffalo. Total length was about 2500 miles. The Detroit to Buffalo line cut though southern Ontario, Canada on Canadian National trackage rights. That route also required a car float operation across the Detroit River. As a result, Wabash’s Buffalo traffic was a fraction of that of competitors Nickel Plate and New York Central. However, Wabash’s Detroit-Kansas City and Detroit-St. Louis service was a force to be reckoned with and well patronized by Michigan’s automakers. The Wabash Cannonball was the name of the daytime passenger run between Detroit and St. Louis. The song of the same name was a hit long before it was ever applied to the train itself. Wabash bought control of the Ann Arbor in 1925 and soon after, Wabash and Delaware & Hudson jointly bought control of the Lehigh Valley (Wabash’s principle connection in Buffalo.) This got the attention of the Pennsylvania Railroad who bought control of Wabash under the auspices of their “Pennsylvania Company” subsidiary in 1928.

As PRR planned their merger with New York Central, it became obvious that they could not take Wabash with them. The first step was to transfer control of Ann Arbor from Wabash to Detroit Toledo & Ironton (also in the Pennsylvania Company family.) Up to that point, Ann Arbor was routinely included in the official Wabash system map. Then PRR arranged for Wabash to be included in the Norfolk & Western-Nickel Plate-Pittsburgh & West Virginia merger that was being planned. PRR didn’t overtly control the N&W but they did have considerable influence over them. The deal was made and the new, larger Norfolk & Western leased the Wabash for 50 years in October of 1964. At that point, Wabash became a paper railroad. They were finally merged out of existence by N&W successor Norfolk Southern in the 1990s.

As PRR planned their merger with New York Central, it became obvious that they could not take Wabash with them. The first step was to transfer control of Ann Arbor from Wabash to Detroit Toledo & Ironton (also in the Pennsylvania Company family.) Up to that point, Ann Arbor was routinely included in the official Wabash system map. Then PRR arranged for Wabash to be included in the Norfolk & Western-Nickel Plate-Pittsburgh & West Virginia merger that was being planned. PRR didn’t overtly control the N&W but they did have considerable influence over them. The deal was made and the new, larger Norfolk & Western leased the Wabash for 50 years in October of 1964. At that point, Wabash became a paper railroad. They were finally merged out of existence by N&W successor Norfolk Southern in the 1990s.

Brand/Importer Information:  Founded in 1906 by Karl Arnold in Nuernberg, K. Arnold & Co. began its life producing tin toys and related items. They produced an extensive line of model ships, doll house items and other toys. In 1935, K. Arnold & Co. hired Max Ernst as their managing director. Ernst, not to be confused with the German realist artist of the same name, was a significant factor in the future of Arnold.

Founded in 1906 by Karl Arnold in Nuernberg, K. Arnold & Co. began its life producing tin toys and related items. They produced an extensive line of model ships, doll house items and other toys. In 1935, K. Arnold & Co. hired Max Ernst as their managing director. Ernst, not to be confused with the German realist artist of the same name, was a significant factor in the future of Arnold.

There are several distinct phases of Arnold's model train production. In the period of 1960 - 1962, Arnold marketed the Arnold Rapido 200 product line; this line was very crude yet it also was a sensation because of its much smaller size than TT.

The next phase was from 1963-1967, when the rapido product line begins to swing toward scale representations of the trains. It is during this period that the "Rapido Coupler" comes into production, beginning its widespread use by all model train manufacturers in N-Scale. It was in 1964 that the term "N-Scale" came into use. Between 1968 and 1970, rapido line of trains reached maturity, notably with its turntable and roundhouse. Arnold entered into a business relationship with the U.S. company Revell around 1968, beginning the marketing of Revell Rapido model trains. This relationship was marked by the beginning of production of more accurate North American prototype models by Arnold. This relationship continued for several years, ending in the late 1960s or early 1970s. Arnold continued their expanded production, with new models until the early 1990s.

On Max Ernst's 1976 retirement, Arnold employed perhaps 200 to 250 people, using three facilities in the Nurnberg area. The Company continued under family control until 1995, when Arnold went into bankruptcy and was sold to Rivarossi of Italy. Rivarossi, in turn, also went bankrupt, leading to the sale of all assets to Hornby of the United Kingdom. Production is carried out in China.

There are several distinct phases of Arnold's model train production. In the period of 1960 - 1962, Arnold marketed the Arnold Rapido 200 product line; this line was very crude yet it also was a sensation because of its much smaller size than TT.

The next phase was from 1963-1967, when the rapido product line begins to swing toward scale representations of the trains. It is during this period that the "Rapido Coupler" comes into production, beginning its widespread use by all model train manufacturers in N-Scale. It was in 1964 that the term "N-Scale" came into use. Between 1968 and 1970, rapido line of trains reached maturity, notably with its turntable and roundhouse. Arnold entered into a business relationship with the U.S. company Revell around 1968, beginning the marketing of Revell Rapido model trains. This relationship was marked by the beginning of production of more accurate North American prototype models by Arnold. This relationship continued for several years, ending in the late 1960s or early 1970s. Arnold continued their expanded production, with new models until the early 1990s.

On Max Ernst's 1976 retirement, Arnold employed perhaps 200 to 250 people, using three facilities in the Nurnberg area. The Company continued under family control until 1995, when Arnold went into bankruptcy and was sold to Rivarossi of Italy. Rivarossi, in turn, also went bankrupt, leading to the sale of all assets to Hornby of the United Kingdom. Production is carried out in China.

Item created by: gdm on 2022-08-09 07:21:14. Last edited by gdm on 2022-08-09 07:25:20

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.