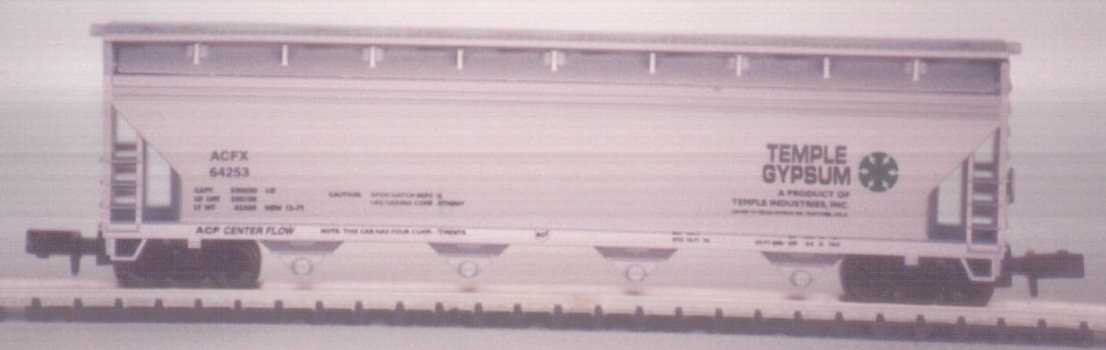

Model Information: This model was originally introduced in 1993. It is somewhat similar to the earlier Roco/Atlas produced 3700-series model which was still available in the 1990s when this new model became available. The earlier models can be distinguished from this one because they are stamped either "Austria" or "Atlas USA" on the underframe. The later models can also be identified by the angled stirrups at each end (as opposed to squared off ones on the Austrian tooling). Lastly, the Chinese versions have several ridges along the side towards the roof-line in a 'washboard' pattern.

This new Chinese production model was specifically identified as modeling the ACF 5250 c.f. Centerflow hopper When this model appeared in the 1994 Atlas catalog it was on the next page after the earlier tooling (apparently many of the old models were still in the warehouse). The new ones were marketed as 'ACF 4-Bay Centerflow® Hopper - All New Mold Work!" as opposed to the older models which were labeled as "ACF 4-Bay Centerflow® Covered Hopper". Atlas' model represents the post-1971 version of the ACF 5250 4-Bay Covered Hopper Car that was used by railroads and private shippers across North America.

This new Chinese production model was specifically identified as modeling the ACF 5250 c.f. Centerflow hopper When this model appeared in the 1994 Atlas catalog it was on the next page after the earlier tooling (apparently many of the old models were still in the warehouse). The new ones were marketed as 'ACF 4-Bay Centerflow® Hopper - All New Mold Work!" as opposed to the older models which were labeled as "ACF 4-Bay Centerflow® Covered Hopper". Atlas' model represents the post-1971 version of the ACF 5250 4-Bay Covered Hopper Car that was used by railroads and private shippers across North America.

Prototype History: Contemporary 2-bay covered hoppers, like ACF's Centerflows, were 100-ton cars designed to haul dense loads, like cement. Their larger 3 and 4-bay brethren, while usually still having 100 ton capacities, were designed for lighter-density loads, like grain or flour. Their sizes had to do with the fact that a low-density product like grain will "cube out" the cubic capacity of a smaller 2-bay car way before you hit the cars' tonnage rating. Conversely, load a 3 or 4-bay covered hopper to its cubic maximum with a dense product like cement, and you'll wind up with a seriously overloaded car tonnage wise. In short, keep the smaller 2-bay cars for heavy commodities, and keep the larger cars for lighter loads like grains, sugar, flour, etc.

Road Name History:  Temple Industries began in 1893 when Thomas L. L. Temple purchased 7,000 acres of timberland in southern Angelina County from John C. Diboll of Louisiana. Southern Pine Lumber Company of Texarkana, Arkansas, had been organized in 1891 as a partnership between Temple, C. M. Putnam, and Ben Whitaker, to sell lumber wholesale. The company folded the same year and was reorganized in 1893. Temple soon became the sole owner. A millsite was constructed at the company town, Diboll, midway between Houston and Shreveport on the Houston, East and West Texas Railway, and production of pine and hardwood lumber began in June 1894. Sixty thousand board feet of lumber was cut per day, and 600 men were employed. The firm was organized as a capital-stock enterprise in 1893. Timber resources came from a strip of land fifty-five miles long and five miles wide along the Neches River in Angelina, Anderson, Cherokee, Houston, and Trinity counties. Temple later purchased other firms and founded the Temple Lumber Company at Pineland. When he died in 1935 his son, Arthur Temple, Sr., became company president. Arthur Temple, Jr., assumed control in 1948, and the company rapidly expanded into fiberboard sheathing, particleboard, and plywood manufacture.

Temple Industries began in 1893 when Thomas L. L. Temple purchased 7,000 acres of timberland in southern Angelina County from John C. Diboll of Louisiana. Southern Pine Lumber Company of Texarkana, Arkansas, had been organized in 1891 as a partnership between Temple, C. M. Putnam, and Ben Whitaker, to sell lumber wholesale. The company folded the same year and was reorganized in 1893. Temple soon became the sole owner. A millsite was constructed at the company town, Diboll, midway between Houston and Shreveport on the Houston, East and West Texas Railway, and production of pine and hardwood lumber began in June 1894. Sixty thousand board feet of lumber was cut per day, and 600 men were employed. The firm was organized as a capital-stock enterprise in 1893. Timber resources came from a strip of land fifty-five miles long and five miles wide along the Neches River in Angelina, Anderson, Cherokee, Houston, and Trinity counties. Temple later purchased other firms and founded the Temple Lumber Company at Pineland. When he died in 1935 his son, Arthur Temple, Sr., became company president. Arthur Temple, Jr., assumed control in 1948, and the company rapidly expanded into fiberboard sheathing, particleboard, and plywood manufacture.

In 1956 Southern Pine merged its Pineland operations into the parent company, which in 1964 was renamed Temple Industries. It built or acquired plants in Arkansas, Alabama, and Georgia in the 1970s to expand particleboard and gypsum wallboard manufacture. In 1973 Temple Industries was acquired by Time, Incorporated, and merged with Time's Eastex pulp and paperboard subsidiary at Evadale, Texas, to form Temple-Eastex. The new company owned more than a million acres of forest in Texas and employed nearly 5,000 people nationwide. In 1984 Time spun off Temple-Eastex and a Time subsidiary, Inland Container Corporation, to form Temple-Inland, based in Diboll, which reported $1 billion in sales in its first year and became one of the nation's primary producers of corrugated boxes, as well as building products, pulp, and paperboard. Subsidiary companies are engaged in mortgage banking, insurance, and real estate development.

Registered Address 101 NORTH FIRST ST DIBOLL, TX 759411932 United States

In 1956 Southern Pine merged its Pineland operations into the parent company, which in 1964 was renamed Temple Industries. It built or acquired plants in Arkansas, Alabama, and Georgia in the 1970s to expand particleboard and gypsum wallboard manufacture. In 1973 Temple Industries was acquired by Time, Incorporated, and merged with Time's Eastex pulp and paperboard subsidiary at Evadale, Texas, to form Temple-Eastex. The new company owned more than a million acres of forest in Texas and employed nearly 5,000 people nationwide. In 1984 Time spun off Temple-Eastex and a Time subsidiary, Inland Container Corporation, to form Temple-Inland, based in Diboll, which reported $1 billion in sales in its first year and became one of the nation's primary producers of corrugated boxes, as well as building products, pulp, and paperboard. Subsidiary companies are engaged in mortgage banking, insurance, and real estate development.

Registered Address 101 NORTH FIRST ST DIBOLL, TX 759411932 United States

Brand/Importer Information: The Freight Yard was a hobby shop that did custom decoration and special runs of other manufacturers' N Scale products. It sold its custom products under several brands or collections: Premiere Editions, by The Freight Yard and Dreams Design.

It was located in Anaheim, California and then moved to 2006 in Phoenix, Arizona.

Established in the late 1980s, it stopped business under this name by the end of the 2000s.

The Freight Yard was owned and operated by Darren J. Cohen. Darren is now operating North Valley Trains.

The Freight Yard / Premiere Editions runs are usually available in series of two to twelve different numbers (suffixed A to M, with I not used).

The first two digits of the stock number correspond to the release year (9x being 199x, and 2x being 200x).

It was located in Anaheim, California and then moved to 2006 in Phoenix, Arizona.

Established in the late 1980s, it stopped business under this name by the end of the 2000s.

The Freight Yard was owned and operated by Darren J. Cohen. Darren is now operating North Valley Trains.

The Freight Yard / Premiere Editions runs are usually available in series of two to twelve different numbers (suffixed A to M, with I not used).

The first two digits of the stock number correspond to the release year (9x being 199x, and 2x being 200x).

Manufacturer Information: 'Atlas Model Railroad' represents the New Jersey manufacturing facility for Atlas brand model railroad products. Atlas also imported European made models in their early years and those items will be noted as having manufacturers set appropriately. In the 1990s Atlas moved all their toolings to China.

Item created by: Alain LM on 2022-06-26 08:51:47. Last edited by Alain LM on 2022-09-25 05:41:25

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.