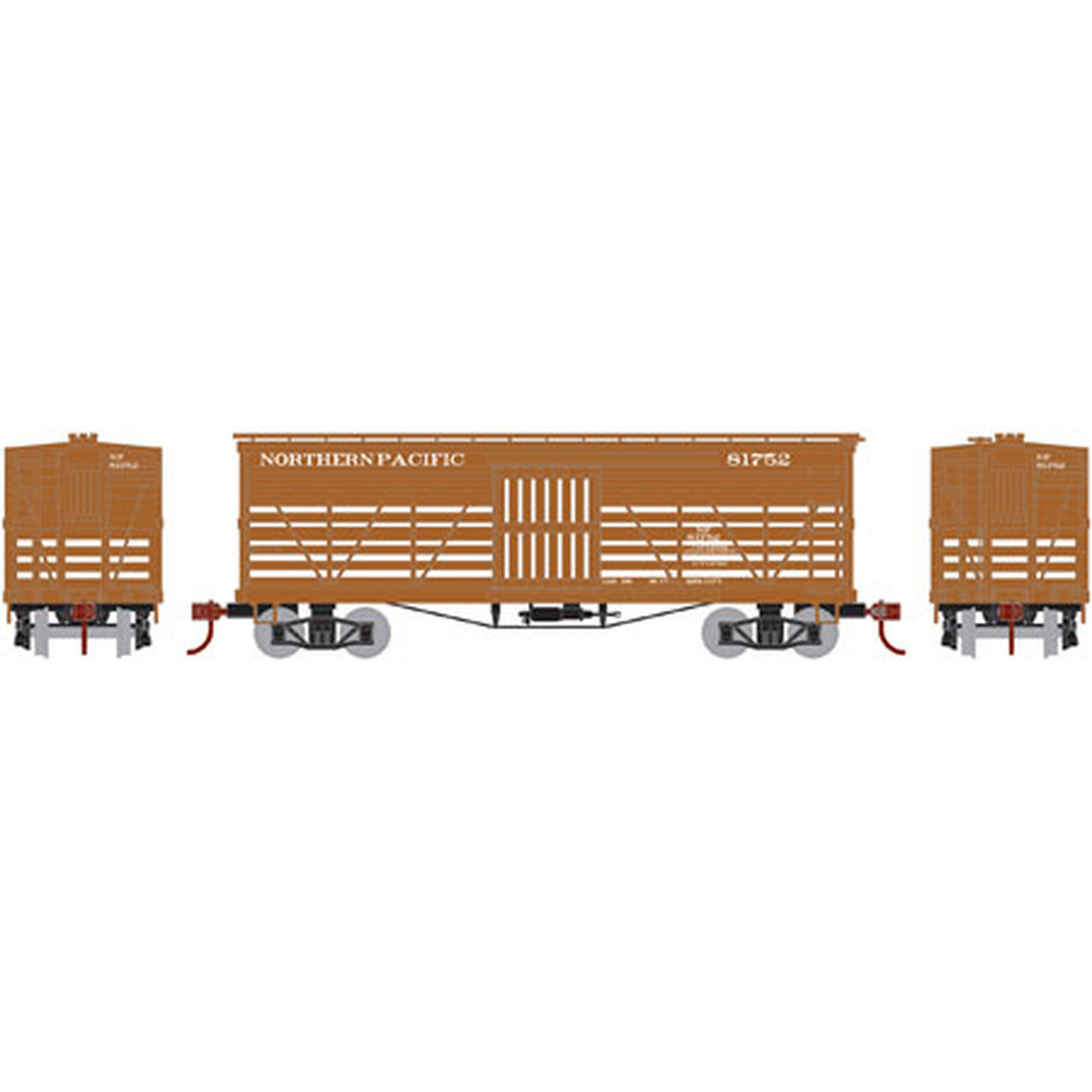

History: In US railroad terminology, a gondola is an open-topped rail vehicle used for transporting loose bulk materials. All-steel gondolas date back to the early part of the 20th century. Because of their low side walls gondolas are also suitable for the carriage of such high-density cargoes as steel plates or coils, or of bulky items such as prefabricated sections of rail track.

Drop-bottom gondolas were equipped with dump doors that operated via a mechanism located in the center of the car body. The drop bottom door provided a time-saving unloading method compared to the usual, labor-intensive procedure. Instead of equipping workmen with shovels to muck out the car’s content, the lever system was used to open the doors thus immediately dumping the load on the ground. Various commodities could be carried in the drop bottom gons, but coal loadings were most common. Many coaling towers had elevated trestle style delivery ramps where the drop bottom gondolas would be spotted and workmen could simply open the dump doors to spill the contents into the coal bins. At facilities with the elevator bucket style of coal dock, a ramp was used that led up to an open grate where the coal would spill through and into the lower coal bins. The gons were “tailor made” for company service such as dumping ballast directly onto track roadbed during maintenance, as well as hauling cinders out of various engine service facilities. Handy they were!

Drop-bottom gondolas were equipped with dump doors that operated via a mechanism located in the center of the car body. The drop bottom door provided a time-saving unloading method compared to the usual, labor-intensive procedure. Instead of equipping workmen with shovels to muck out the car’s content, the lever system was used to open the doors thus immediately dumping the load on the ground. Various commodities could be carried in the drop bottom gons, but coal loadings were most common. Many coaling towers had elevated trestle style delivery ramps where the drop bottom gondolas would be spotted and workmen could simply open the dump doors to spill the contents into the coal bins. At facilities with the elevator bucket style of coal dock, a ramp was used that led up to an open grate where the coal would spill through and into the lower coal bins. The gons were “tailor made” for company service such as dumping ballast directly onto track roadbed during maintenance, as well as hauling cinders out of various engine service facilities. Handy they were!

Railroad/Company: This set of items is comprised of more than one name. Please look at the component items for details on the specific roadnames and/or manufacturers.

Item Links: We found: 1 different collections associated with Rail - Rolling Stock (Freight) - Steel, Drop Bottom

- Collection N Scale Model Trains: 438 different items.

Item created by: gdm on 2018-03-03 12:38:47

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.