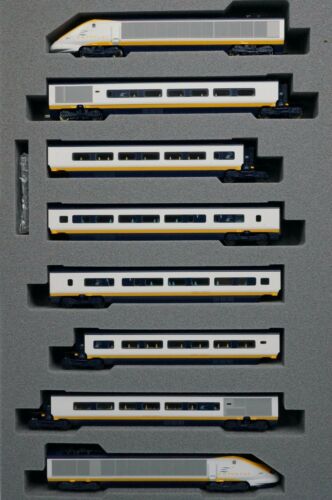

Model Information: This model provides stable operation with or without container loads due to Kato's new innovative heavier material steel compound plastic used for the construction of the well cars. Each container has a magnet and a metal plate to hold it securely to the well car bottom or to the top of the lower Kato container.

Each 5-well MAXI-I set includes ten removable 40-foot containers, all of which are interchangeable with our other container sets or MAXI-IV Well Cars. The packaging is designed for the separated storage of the articulated unit, providing ease and security when not in use. The MAXI-I has resilient plastic connectors between the wells that allow for easy connecting and disengaging for both operation and storage.

Each 5-well MAXI-I set includes ten removable 40-foot containers, all of which are interchangeable with our other container sets or MAXI-IV Well Cars. The packaging is designed for the separated storage of the articulated unit, providing ease and security when not in use. The MAXI-I has resilient plastic connectors between the wells that allow for easy connecting and disengaging for both operation and storage.

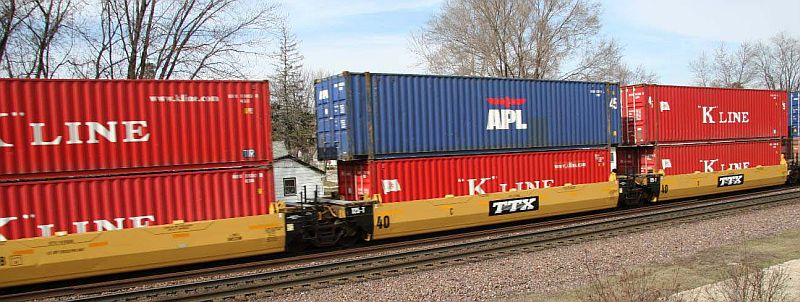

Prototype History: Like its cousin, the Gunderson Maxi-Stack IV, the Maxi-Stack I is a multi-unit well car designed to carry two stacked intermodal shipping containers. While its base well is 40', it can accept larger containers such as 45', 48' and even 53' in the top position, making the car a versatile addition to a railroad's intermodal services. The Maxi-Stack I is a five-unit well car, unlike its 53' cousin Maxi-Stack IV that is a three-unit car, giving each car a greater capacity even though the individual wells are a smaller size. Introduced in 1988, the Maxi-Stack I is still available in Gunderson (now GBX) catalog in a modernized version as of the early 2020's.

Road Name History: (From Wikipedia) A.P. Moller-Maersk Group, also known as Maersk, is a Danish business conglomerate. A.P. Moller-Maersk Group has activities in a variety of business sectors, primarily within the transportation and energy sectors. It has been the largest container ship operator and supply vessel operator in the world since 1996.

A.P. Moller-Maersk Group is based in Copenhagen, Denmark, with subsidiaries and offices in more than 135 countries worldwide and around 89,000 employees. It ranked 148 on the Forbes Global 2000 list for 2015.

The largest operating unit in A.P. Moller-Maersk by revenue and staff (around 25,000 employees in 2012) is Maersk Line. In 2013 the company described itself as the world's largest overseas cargo carrier and operated over 600 vessels with 3.8 million Twenty-foot equivalent unit (TEU) container capacity. As per September 2015, being still the largest container fleet, it holds 15.1% of the global TEU.

In 2006, the largest container ship in the world to that date, the E-class vessel Emma Maersk, was delivered to Maersk Line from Odense Steel Shipyard. Seven other sisterships have since been built, and on 21 February 2011, Maersk ordered 10 even larger container ships from Daewoo, the Triple E class, each with a capacity of 18,000 containers. The first were delivered in 2013. It held options for 10-20 more, and in June 2011 placed follow-on orders for a second batch of ten sisterships (to the same design) with the same shipyard, but cancelled its option for a third batch of ten.

A.P. Moller-Maersk Group is based in Copenhagen, Denmark, with subsidiaries and offices in more than 135 countries worldwide and around 89,000 employees. It ranked 148 on the Forbes Global 2000 list for 2015.

The largest operating unit in A.P. Moller-Maersk by revenue and staff (around 25,000 employees in 2012) is Maersk Line. In 2013 the company described itself as the world's largest overseas cargo carrier and operated over 600 vessels with 3.8 million Twenty-foot equivalent unit (TEU) container capacity. As per September 2015, being still the largest container fleet, it holds 15.1% of the global TEU.

In 2006, the largest container ship in the world to that date, the E-class vessel Emma Maersk, was delivered to Maersk Line from Odense Steel Shipyard. Seven other sisterships have since been built, and on 21 February 2011, Maersk ordered 10 even larger container ships from Daewoo, the Triple E class, each with a capacity of 18,000 containers. The first were delivered in 2013. It held options for 10-20 more, and in June 2011 placed follow-on orders for a second batch of ten sisterships (to the same design) with the same shipyard, but cancelled its option for a third batch of ten.

Brand/Importer Information: KATO U.S.A. was established in 1986, with the first U.S. locomotive model (the GP38-2, in N-Scale) released in 1987. Since that time, KATO has come to be known as one of the leading manufacturers of precision railroad products for the modeling community. KATO's parent company, Sekisui Kinzoku Co., Ltd., is headquartered in Tokyo, Japan.

In addition to producing ready-to-run HO and N scale models that are universally hailed for their high level of detail, craftsmanship and operation, KATO also manufactures UNITRACK. UNITRACK is the finest rail & roadbed modular track system available to modelers today. With the track and roadbed integrated into a single piece, UNITRACK features a nickel-silver rail and a realistic-looking roadbed. Patented UNIJOINERS allow sections to be snapped together quickly and securely, time after time if necessary.

The Kato U.S.A. office and warehouse facility is located in Schaumburg, Illinois, approximately 30 miles northwest of Chicago. All research & development of new North American products is performed here, in addition to the sales and distribution of merchandise to a vast network of wholesale representatives and retail dealers. Models requiring service sent in by hobbyists are usually attended to at this location as well. The manufacturing of all KATO products is performed in Japan.

Supporters of KATO should note that there is currently no showroom or operating exhibit of models at the Schaumburg facility. Furthermore, model parts are the only merchandise sold directly to consumers. (Please view the Parts Catalog of this website for more specific information.)

In addition to producing ready-to-run HO and N scale models that are universally hailed for their high level of detail, craftsmanship and operation, KATO also manufactures UNITRACK. UNITRACK is the finest rail & roadbed modular track system available to modelers today. With the track and roadbed integrated into a single piece, UNITRACK features a nickel-silver rail and a realistic-looking roadbed. Patented UNIJOINERS allow sections to be snapped together quickly and securely, time after time if necessary.

The Kato U.S.A. office and warehouse facility is located in Schaumburg, Illinois, approximately 30 miles northwest of Chicago. All research & development of new North American products is performed here, in addition to the sales and distribution of merchandise to a vast network of wholesale representatives and retail dealers. Models requiring service sent in by hobbyists are usually attended to at this location as well. The manufacturing of all KATO products is performed in Japan.

Supporters of KATO should note that there is currently no showroom or operating exhibit of models at the Schaumburg facility. Furthermore, model parts are the only merchandise sold directly to consumers. (Please view the Parts Catalog of this website for more specific information.)

Item created by: gdm on 2016-08-04 14:29:04. Last edited by grothe77 on 2020-05-25 14:51:24

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.