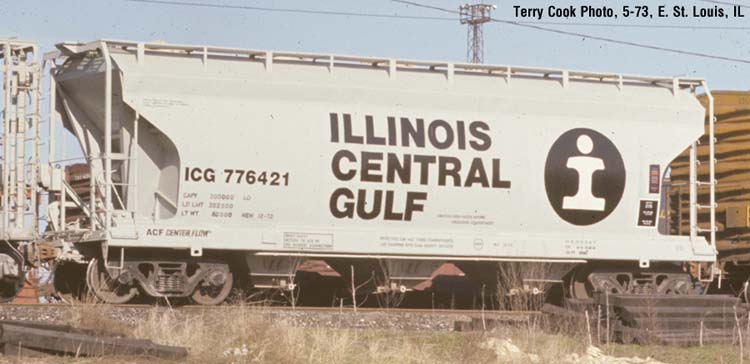

Model Information: This model was first released by Atlas in 2006. Unlike many older toolings which were 'put out to pasture' in the Trainman line, this model was Trainman from the get-go. This means it was designed from the ground-up to be durable and relatively inexpensive to produce. It is a nice quality car, and while not as inexpensive as one might hope for an item designed for a lower price point, it is surprisingly well detailed.

Prototype History: Covered hoppers such as these are used to transport any dry bulk material that you don't want exposed to the elements. Salt, fertilizer, some dry chemicals, and bauxite are common loads for this car. Over 200 were built from 1967 to 1972. The three-compartment ACF® 3560 Center Flow Covered Hopper was designed for the transport of high-density dry bulk ladings of 50 – 60 pounds per cubic foot. The 100-ton car was designed to fit into the smallest modern plate diagram dimensions, Plate B.

Road Name History:  Temple Industries began in 1893 when Thomas L. L. Temple purchased 7,000 acres of timberland in southern Angelina County from John C. Diboll of Louisiana. Southern Pine Lumber Company of Texarkana, Arkansas, had been organized in 1891 as a partnership between Temple, C. M. Putnam, and Ben Whitaker, to sell lumber wholesale. The company folded the same year and was reorganized in 1893. Temple soon became the sole owner. A millsite was constructed at the company town, Diboll, midway between Houston and Shreveport on the Houston, East and West Texas Railway, and production of pine and hardwood lumber began in June 1894. Sixty thousand board feet of lumber was cut per day, and 600 men were employed. The firm was organized as a capital-stock enterprise in 1893. Timber resources came from a strip of land fifty-five miles long and five miles wide along the Neches River in Angelina, Anderson, Cherokee, Houston, and Trinity counties. Temple later purchased other firms and founded the Temple Lumber Company at Pineland. When he died in 1935 his son, Arthur Temple, Sr., became company president. Arthur Temple, Jr., assumed control in 1948, and the company rapidly expanded into fiberboard sheathing, particleboard, and plywood manufacture.

Temple Industries began in 1893 when Thomas L. L. Temple purchased 7,000 acres of timberland in southern Angelina County from John C. Diboll of Louisiana. Southern Pine Lumber Company of Texarkana, Arkansas, had been organized in 1891 as a partnership between Temple, C. M. Putnam, and Ben Whitaker, to sell lumber wholesale. The company folded the same year and was reorganized in 1893. Temple soon became the sole owner. A millsite was constructed at the company town, Diboll, midway between Houston and Shreveport on the Houston, East and West Texas Railway, and production of pine and hardwood lumber began in June 1894. Sixty thousand board feet of lumber was cut per day, and 600 men were employed. The firm was organized as a capital-stock enterprise in 1893. Timber resources came from a strip of land fifty-five miles long and five miles wide along the Neches River in Angelina, Anderson, Cherokee, Houston, and Trinity counties. Temple later purchased other firms and founded the Temple Lumber Company at Pineland. When he died in 1935 his son, Arthur Temple, Sr., became company president. Arthur Temple, Jr., assumed control in 1948, and the company rapidly expanded into fiberboard sheathing, particleboard, and plywood manufacture.

In 1956 Southern Pine merged its Pineland operations into the parent company, which in 1964 was renamed Temple Industries. It built or acquired plants in Arkansas, Alabama, and Georgia in the 1970s to expand particleboard and gypsum wallboard manufacture. In 1973 Temple Industries was acquired by Time, Incorporated, and merged with Time's Eastex pulp and paperboard subsidiary at Evadale, Texas, to form Temple-Eastex. The new company owned more than a million acres of forest in Texas and employed nearly 5,000 people nationwide. In 1984 Time spun off Temple-Eastex and a Time subsidiary, Inland Container Corporation, to form Temple-Inland, based in Diboll, which reported $1 billion in sales in its first year and became one of the nation's primary producers of corrugated boxes, as well as building products, pulp, and paperboard. Subsidiary companies are engaged in mortgage banking, insurance, and real estate development.

Registered Address 101 NORTH FIRST ST DIBOLL, TX 759411932 United States

In 1956 Southern Pine merged its Pineland operations into the parent company, which in 1964 was renamed Temple Industries. It built or acquired plants in Arkansas, Alabama, and Georgia in the 1970s to expand particleboard and gypsum wallboard manufacture. In 1973 Temple Industries was acquired by Time, Incorporated, and merged with Time's Eastex pulp and paperboard subsidiary at Evadale, Texas, to form Temple-Eastex. The new company owned more than a million acres of forest in Texas and employed nearly 5,000 people nationwide. In 1984 Time spun off Temple-Eastex and a Time subsidiary, Inland Container Corporation, to form Temple-Inland, based in Diboll, which reported $1 billion in sales in its first year and became one of the nation's primary producers of corrugated boxes, as well as building products, pulp, and paperboard. Subsidiary companies are engaged in mortgage banking, insurance, and real estate development.

Registered Address 101 NORTH FIRST ST DIBOLL, TX 759411932 United States

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: Lethe on 2016-02-05 13:54:20. Last edited by CNW400 on 2020-06-03 11:48:50

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.