Model Information: First release in October of 2004, this model features:

The cars followed a common bent-barrel tank design that helps the product drain and unload easier. These cars are jacketed and insulated, and have exterior coil pipes to heat the commodity to promote faster unloading. Midland food-grade butterfly unload valves and Midland exterior spring safety valves were common appliances used on these cars. The biggest variation in the car production was in the manway / top platform arrangement. Several arrangements were specified by large shippers; for example ADM, Cargill, Corn Products, GATX, MCP, and Staley to name a few.

These tank cars are commonly used to transport varying grades of Corn Syrup, Liquid Sugar, and Molasses from processing facilities to bulk distribution centers and other end-users throughout the US and Canada. They are a very common sight on today's railroads, and they have been for two decades. This initial release features three of the most common manway/top platform arrangements as specified by ADM, Cargill, and Corn Products (among others).

- Three separate styles of manway / platform / ladder arrangements (used as appropriate per road name)

- Fine scale railings

- Separately applied brake rigging

- Separately applied manway ?clamshell?-style cover used when appropriate per road name

- 100-Ton Roller Bearing Trucks

- Accurate painting and printing

- Full stand-alone brake system details

- Bottom outlet valve detail

- Stand-alone heater coil pipes

- Highly detailed body with prototypical jacket seams

- See-through top platform grating

The cars followed a common bent-barrel tank design that helps the product drain and unload easier. These cars are jacketed and insulated, and have exterior coil pipes to heat the commodity to promote faster unloading. Midland food-grade butterfly unload valves and Midland exterior spring safety valves were common appliances used on these cars. The biggest variation in the car production was in the manway / top platform arrangement. Several arrangements were specified by large shippers; for example ADM, Cargill, Corn Products, GATX, MCP, and Staley to name a few.

These tank cars are commonly used to transport varying grades of Corn Syrup, Liquid Sugar, and Molasses from processing facilities to bulk distribution centers and other end-users throughout the US and Canada. They are a very common sight on today's railroads, and they have been for two decades. This initial release features three of the most common manway/top platform arrangements as specified by ADM, Cargill, and Corn Products (among others).

Prototype History: The 17,600 Gallon Corn Syrup Tank Car was built in large numbers by Trinity Industries between 1984 and 1998. They are commonly used in the transport of corn syrup, liquid sugar and molasses from processing facilities to bulk distribution centers. Over 7,000 cars were built and most remain in active service today.

The cars followed a common bent-barrel tank design that helps the product drain and unload easier. These cars are jacketed and insulated, and have exterior coil pipes to heat the commodity to promote faster unloading. Midland food-grade butterfly unload valves and Midland exterior spring safety valves were common appliances used on these cars. The biggest variation in the car production was in the manway / top platform arrangement. Several arrangements were specified by large shippers; for example ADM, Cargill, Corn Products, GATX, MCP, and Staley to name a few.

These tank cars are commonly used to transport varying grades of Corn Syrup, Liquid Sugar, and Molasses from processing facilities to bulk distribution centers and other end-users throughout the US and Canada. They are a very common sight on today's railroads, and they have been for two decades. This initial release features three of the most common manway/top platform arrangements as specified by ADM, Cargill, and Corn Products (among others).

The cars followed a common bent-barrel tank design that helps the product drain and unload easier. These cars are jacketed and insulated, and have exterior coil pipes to heat the commodity to promote faster unloading. Midland food-grade butterfly unload valves and Midland exterior spring safety valves were common appliances used on these cars. The biggest variation in the car production was in the manway / top platform arrangement. Several arrangements were specified by large shippers; for example ADM, Cargill, Corn Products, GATX, MCP, and Staley to name a few.

These tank cars are commonly used to transport varying grades of Corn Syrup, Liquid Sugar, and Molasses from processing facilities to bulk distribution centers and other end-users throughout the US and Canada. They are a very common sight on today's railroads, and they have been for two decades. This initial release features three of the most common manway/top platform arrangements as specified by ADM, Cargill, and Corn Products (among others).

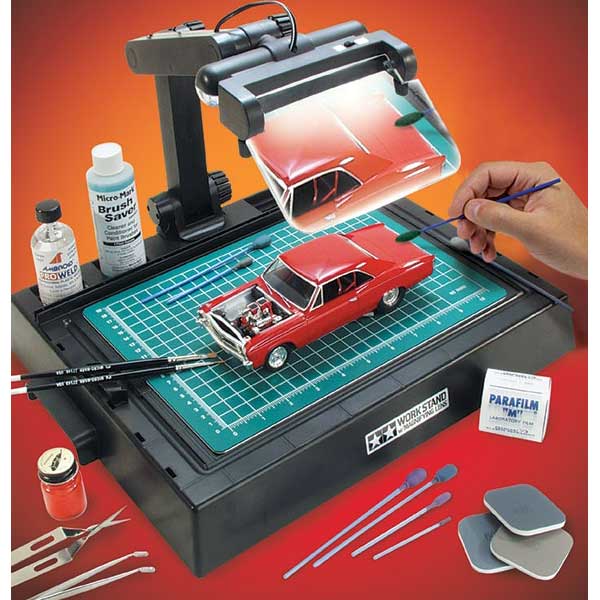

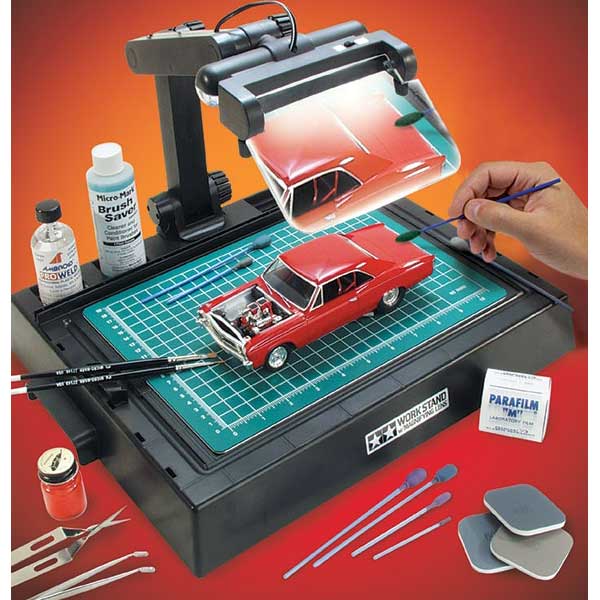

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: CNW400 on 2022-07-31 11:18:19

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.