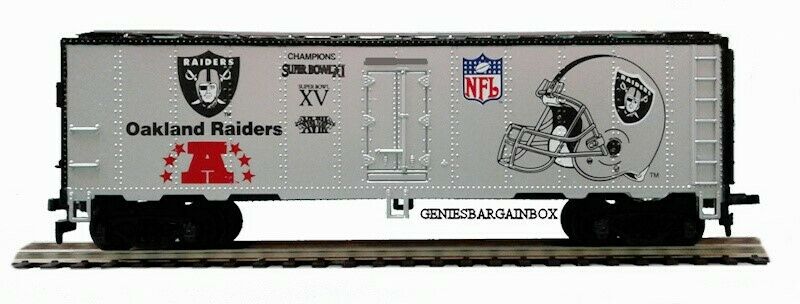

General Information About Item: No Company Name, Road Letters or Reporting numbers on the car.

The Brand / Manufacture is actually stamped "Mantua" on the under carriage.

Prototype Information: A refrigerator car (or “reefer”) is a refrigerated boxcar (US) or van (UIC), a piece of railroad rolling stock designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple insulated boxcars and ventilated boxcars (commonly used for transporting fruit), neither of which are fitted with cooling apparatus. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or utilize carbon dioxide (either as dry ice, or in liquid form) as a cooling agent. Milk cars (and other types of “express” reefers) may or may not include a cooling system, but are equipped with high-speed trucks and other modifications that allow them to travel with passenger trains.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

Road/Company Information:  "Dimensional Data" here means painted models with printed body specifications and no road/reporting letters/marks or road Name/livery. The data typically consists of internal and external dimensions, capacities, weight information and specific characteristics of freight cars, trailers and containers.

"Dimensional Data" here means painted models with printed body specifications and no road/reporting letters/marks or road Name/livery. The data typically consists of internal and external dimensions, capacities, weight information and specific characteristics of freight cars, trailers and containers.

The Association of American Railroads (AAR) sets standards for the uniform marking of freight cars with regard to car ownership, weight, load capacity, dimensions, and maintenance. In addition, car owners choose to display data relating to various devices and equipment so the cars may be properly used and repaired.

CAPY (nominal capacity) is the intended load-carrying capacity of the car, to the nearest 1000 pounds. This is determined by the structural strength of the car's underframe and the size of the journal bearings of the car's trucks.

LD LMT (load limit) is the maximum weight of lading that can be carried by the car, to the nearest 100 pounds. This is determined by subtracting the weight of the car when empty from the total allowable gross weight given the size of the car's journal bearings. The load limit for a car is usually a bit greater than its capacity; the two figures can be equal, but capacity can never exceed load limit.

LT WT (light, or empty, weight) is the weight of the car when empty. Accompanying the light weight marking is a date indicating when the railroad or owner last verified the car's weight. The letters for this mark are not always reporting marks; sometimes a location code is used. NEW and a date indicates that the weight shown is the car's as-built weight, and that it hasn't been field-checked since.

The Association of American Railroads (AAR) sets standards for the uniform marking of freight cars with regard to car ownership, weight, load capacity, dimensions, and maintenance. In addition, car owners choose to display data relating to various devices and equipment so the cars may be properly used and repaired.

CAPY (nominal capacity) is the intended load-carrying capacity of the car, to the nearest 1000 pounds. This is determined by the structural strength of the car's underframe and the size of the journal bearings of the car's trucks.

LD LMT (load limit) is the maximum weight of lading that can be carried by the car, to the nearest 100 pounds. This is determined by subtracting the weight of the car when empty from the total allowable gross weight given the size of the car's journal bearings. The load limit for a car is usually a bit greater than its capacity; the two figures can be equal, but capacity can never exceed load limit.

LT WT (light, or empty, weight) is the weight of the car when empty. Accompanying the light weight marking is a date indicating when the railroad or owner last verified the car's weight. The letters for this mark are not always reporting marks; sometimes a location code is used. NEW and a date indicates that the weight shown is the car's as-built weight, and that it hasn't been field-checked since.

Brand/Importer Information: John Tyler founded the original Mantua Toy & Metal Products Company in 1926 with other members of his family, selling trains under the Mantua name by 1930. The shift towards “ready-to-run” (RTR) train sets in the postwar era led to the creation of the Tyler Manufacturing Company in 1952, better known as TYCO. Mantua continued to exist throughout the ’50s and into the 1960s manufacturing kits, while the TYCO line sold already built and ready to operate model trains largely in set form. The Mantua and TYCO empire was a family owned business from its inception. John Tyler’s son, Norman Tyler, was named president of TYCO Industries, Inc. the combined Mantua and TYCO companies, in 1967.

The company was eventually sold to Consolidated Foods, with Norman Tyler remaining on the board. Production was moved to Hong Kong, and the original Woodbury Heights factory was deemed redundant. The Mantua name was re-introduced in 1977 when Tyler purchased the factory in and continued as an independent company releasing HO-scale trains until 2002.

Mantua offered steam locomotive kits, plus ready to run examples. Freight car offerings included classic Mantua tooling, plus later the former Lindberg Line tooling was re-introduced by the company. The final production year for Mantua was 2001. “Mantua Classics” continues today as part of the Model Power line, which is distributed by Model Rectifier Corp. (MRC).

The company was eventually sold to Consolidated Foods, with Norman Tyler remaining on the board. Production was moved to Hong Kong, and the original Woodbury Heights factory was deemed redundant. The Mantua name was re-introduced in 1977 when Tyler purchased the factory in and continued as an independent company releasing HO-scale trains until 2002.

Mantua offered steam locomotive kits, plus ready to run examples. Freight car offerings included classic Mantua tooling, plus later the former Lindberg Line tooling was re-introduced by the company. The final production year for Mantua was 2001. “Mantua Classics” continues today as part of the Model Power line, which is distributed by Model Rectifier Corp. (MRC).

Manufacturer Information: John Tyler founded the original Mantua Toy & Metal Products Company in 1926 with other members of his family, selling trains under the Mantua name by 1930. The shift towards “ready-to-run” (RTR) train sets in the postwar era led to the creation of the Tyler Manufacturing Company in 1952, better known as TYCO. Mantua continued to exist throughout the ’50s and into the 1960s manufacturing kits, while the TYCO line sold already built and ready to operate model trains largely in set form. The Mantua and TYCO empire was a family owned business from its inception. John Tyler’s son, Norman Tyler, was named president of TYCO Industries, Inc. the combined Mantua and TYCO companies, in 1967.

The company was eventually sold to Consolidated Foods, with Norman Tyler remaining on the board. Production was moved to Hong Kong, and the original Woodbury Heights factory was deemed redundant. The Mantua name was re-introduced in 1977 when Tyler purchased the factory in and continued as an independent company releasing HO-scale trains until 2002.

Mantua offered steam locomotive kits, plus ready to run examples. Freight car offerings included classic Mantua tooling, plus later the former Lindberg Line tooling was re-introduced by the company. The final production year for Mantua was 2001. “Mantua Classics” continues today as part of the Model Power line, which is distributed by Model Rectifier Corp. (MRC).

The company was eventually sold to Consolidated Foods, with Norman Tyler remaining on the board. Production was moved to Hong Kong, and the original Woodbury Heights factory was deemed redundant. The Mantua name was re-introduced in 1977 when Tyler purchased the factory in and continued as an independent company releasing HO-scale trains until 2002.

Mantua offered steam locomotive kits, plus ready to run examples. Freight car offerings included classic Mantua tooling, plus later the former Lindberg Line tooling was re-introduced by the company. The final production year for Mantua was 2001. “Mantua Classics” continues today as part of the Model Power line, which is distributed by Model Rectifier Corp. (MRC).

Item created by: luchestr on 2022-05-13 18:38:36. Last edited by luchestr on 2023-12-12 18:46:34

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.