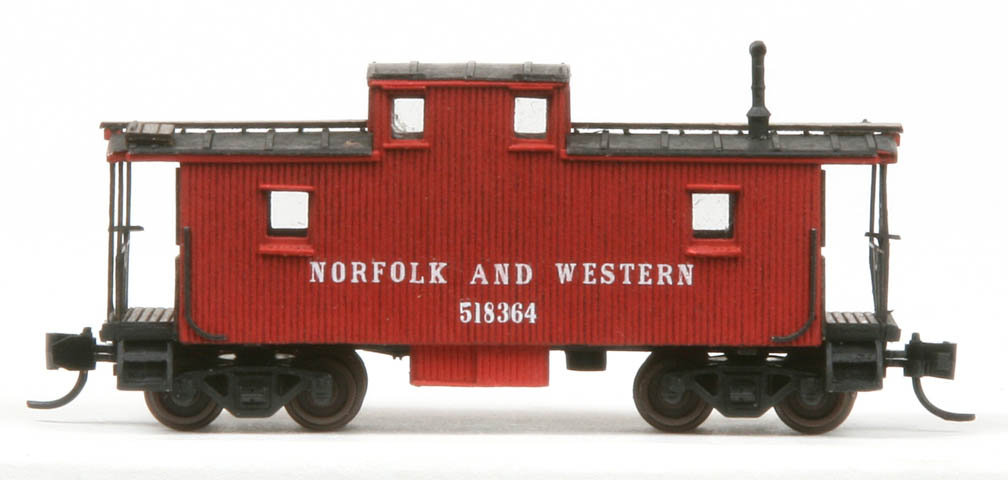

Specific Item Information: Kit No. 552 features: 100% laser-cut components with custom laser-scribed Birch plywood side, end walls, and cupola; Tab & Slot carbody construction; Peel & Stick window, door, and trim assembly; laser-cut underframe, end platforms, ladders, end railing, hand grabs, toilet hopper, window glazing, tool box, and brake wheels; cast resin platform steps and brake gear; plastic smokejack; and fully illustrated instructions that provide information on painting and decaling the assembled model.

Model Information: Includes 100% laser-cut components with custom laser-scribed Birch plywood side, end walls, and cupola; Tab & Slot carbody construction; Peel & Stick window, door, and trim assembly

Laser-cut underframe, end platforms, ladders, end railing, hand grabs, window glazing, truss rods, and brake wheels

Cast resin platform steps and brake gear; plastic smokejack; custom decals by Tichy Train Group; and fully illustrated instructions that provide information on painting and decaling the assembled model

In addition, the N scale kit provides for optional details too such as square or rounded body corner posts; side windows that can be modeled open or closed; two different styles of roofwalks; and cupola end window variation

We recommend the purchase of Micro-Trains No.1015-1 Universal Body Mount Couplers, Atlas No. 22061 Friction Bearing Caboose Trucks, and paint and glue of your choice for the completion of this kit.

Prototype History: The origins of the railroad caboose appear to date back to the 1840s when Nat Williams, a conductor of the Auburn & Syracuse Railroad (a later affiliate of the New York Central) became fed up with cramped and uncomfortable quarters to do paperwork (a common job of the conductor, whose responsibility is general oversight and control of a train, passenger or freight), which was usually done in either a free space of a passenger car or combine/baggage car. To fix this problem, Williams found an unused boxcar and using a simple box and barrel, as a seat and desk, set up shop in the car to do his duties. Not only did he find out he had plenty of room to work but also figured that he could use the unused space to store tools (flags, lanterns, spare parts, etc.) and other essentials to have on board whenever needed (such things become commonly stored on the caboose).

Perhaps the most striking feature ever applied to the railroad caboose was its cupola. According to the story, conductor T.B. Watson of the Chicago & North Western in the 1860s reportedly used a hole in a boxcar’s roof (which he was using as a caboose) to get a better vantage point of the train ahead. It is said that Watson was amazed by the view afforded from the position being able to not only see the train ahead but also from all sides, and to the rear as well. He apparently convinced C&NW shop forces to construct a type of open observation box onto an existing singe-level caboose with windows all around where one could sit and view their surroundings. The rest, as they say, is history and the common cupola was born.

Perhaps the most striking feature ever applied to the railroad caboose was its cupola. According to the story, conductor T.B. Watson of the Chicago & North Western in the 1860s reportedly used a hole in a boxcar’s roof (which he was using as a caboose) to get a better vantage point of the train ahead. It is said that Watson was amazed by the view afforded from the position being able to not only see the train ahead but also from all sides, and to the rear as well. He apparently convinced C&NW shop forces to construct a type of open observation box onto an existing singe-level caboose with windows all around where one could sit and view their surroundings. The rest, as they say, is history and the common cupola was born.

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

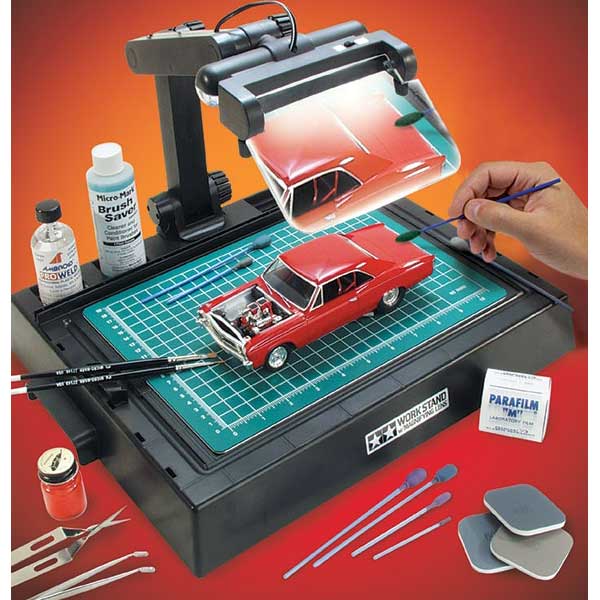

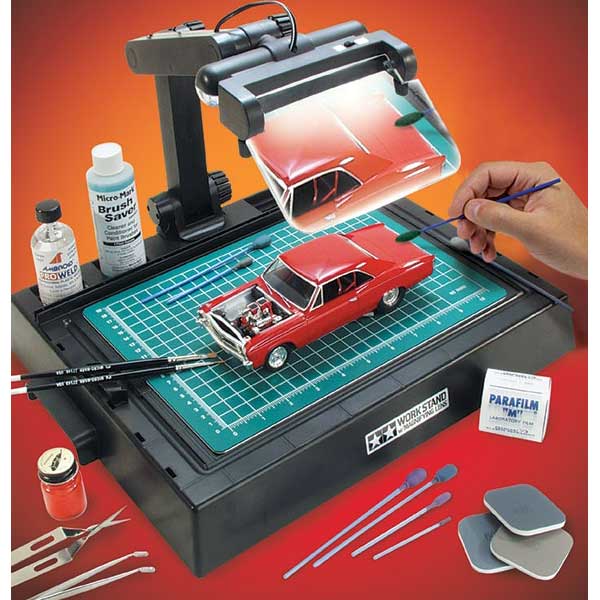

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: LASERKITS are designed in a Computer Assisted Drafting (CAD) program, then laser-machined at our computer-controlled laser workstations.

LASERKITS are cut and engraved from high quality woods (and occasionally styrene) with incredible precision and accuracy. The resulting edges are clean, need little, if any, sanding, and yield precise details, and exact-fitting parts.

There is no frustrating, time-consuming, board by board construction with LASERKITS. Side and roof pieces are tabbed and slotted, so no error can be made during assembly. Windows, doors, roofing materials, shingles, and trim boards are all laser-cut, and have a self adhesive backing which has been tested in the St. Louis summer heat and humidity, and found to hold under the most adverse conditions.

American Model Builders, Inc. 8229 Brentwood Industrial Drive St. Louis, MO 63144 Phone: 314-646-8588 Fax: 314-646-8583 Email: laserkit@sbcglobal.net

LASERKITS are cut and engraved from high quality woods (and occasionally styrene) with incredible precision and accuracy. The resulting edges are clean, need little, if any, sanding, and yield precise details, and exact-fitting parts.

There is no frustrating, time-consuming, board by board construction with LASERKITS. Side and roof pieces are tabbed and slotted, so no error can be made during assembly. Windows, doors, roofing materials, shingles, and trim boards are all laser-cut, and have a self adhesive backing which has been tested in the St. Louis summer heat and humidity, and found to hold under the most adverse conditions.

American Model Builders, Inc. 8229 Brentwood Industrial Drive St. Louis, MO 63144 Phone: 314-646-8588 Fax: 314-646-8583 Email: laserkit@sbcglobal.net

Item created by: CNW400 on 2022-03-04 14:38:57

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.