Model Information: This body style is for the Rivarossi and Arnold versions.

This model was first produced by Rivarossi for Atlas in 1971. The trucks are marked 'Made in Italy' with a Rivarossi logo and an Atlas logo. The motor is visible from below on the powered cow. On the dummy calf, a large hollow can be seen from the bottom of the model, corresponding to the missing motor.

After Atlas stopped ordering them ca. 1977, Rivarossi continued selling them with its own brand and reference (#91xx) and released one additional paint scheme (SP Black Widow) in 1980. Con-Cor also began importing the Rivarossi model. On this model, the trucks are marked 'Made in Italy' with a Rivarossi logo only.

The Rivarossi/Con-Cor version was available powered or unpowered, for both the cow and the calf.

The boxes can be labeled with a Rivarossi stock number on one end and a Con-Cor stock number on the other end, sometimes printed on a Rivarossi label.

Models not in Rivarossi catalog, so only sold by Con-Cor, may still show a Rivarossi stock number, corresponding to the type of chassis - #9288 (dummy calf) or #9289 (dummy cow) or #9290 (powered cow) - on one side and a Con-Cor stock number on the other side. The Con-Cor number was on a sticker which tended to detach with age, leaving only the printed Rivarossi number. Hence many classifieds are using the non-distinctive Rivarossi number 9288 or 9289 or 9890.

At a certain point ca. 1985, apparently dissatisfied with the mechanisms made by Rivarossi, Con-Cor had Kato design a new, more reliable, mechanism but continued use of the Rivarossi shell. This new Kato/Rivarossi hybrid was produced until 1989. The change of mechanism only applied to the 'cow' powered unit; the 'calf' dummy unit continued to be fully made by Rivarossi. On the powered cow, the trucks are marked '17712/Made in Japan' with Kato logo and the fuel tank is marked 'Con-Cor' on the bottom.

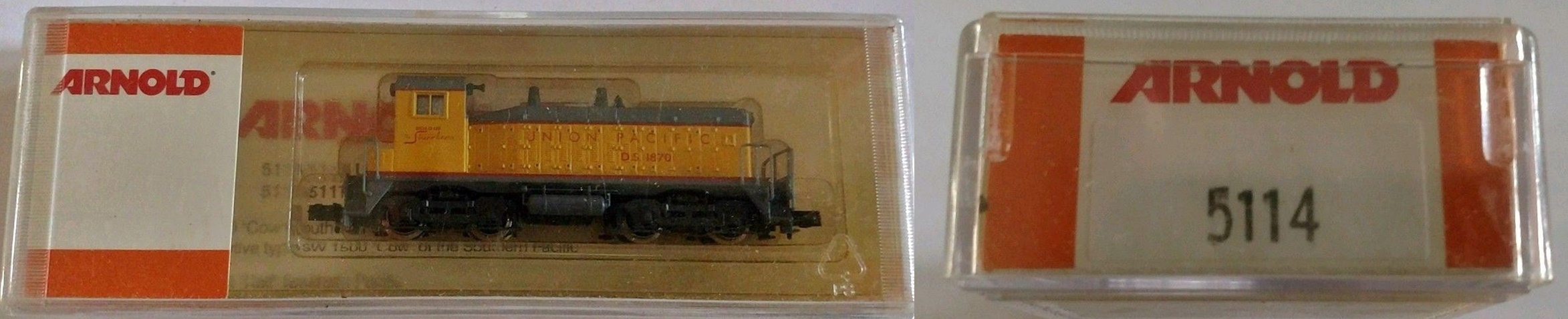

In 1996, Arnold/Rivarossi re-released the same model with yet another new mechanism and a few improvements of the shell (thinner handrails and tank details). On this model, the fuel tank is marked 'Arnold/Made in Germany'. The couplers are truck-mounted.

At this point Con-Cor released a new version of the model this time using a Chinese manufactured mechanism, but with the shell still more or less the same. These Chinese versions were marketed as SW-1200s. The bottom of the trucks is marked '17712/Made in China', without logo.

Con-Cor stopped making their version during the downsizing in 2005 and Arnold stopped producing theirs in 2006 with the bankruptcy.

The model was designed from early EMD drawings for the SW1500 prototype, that were quite similar to the SW1200 drawings. Eventually the final SW1500 prototype was released with significant changes to the early drawing. So though the model is sold as a SW1500, it is actually closer to a SW1200 than to a SW1500. Moreover, if a cow-calf version of the SW1200 (TR12) was offered in the catalog, it was actually never purchased. No cow-calf version of the SW1500 was ever envisaged.

Review Courtesy of Doug Gosha: The Rivarossi model is a plastic shell and separate walkway molding over a zamac frame. There is an additional weight that fits into the cab portion of the shell. The same basic Rivarossi motor is used as in their other A1G locomotives but in a quite different configuration. In this case, the motor has a double-ended shaft with a worm on each end. Due to considerable space limitations in this small chassis, the worm diameters are much smaller than on the other Rivarossi A1G locos. The motor is kind of suspended under the zamac frame in an opening in the center with a spring sheet metal retainer that passes through holes in the top of the frame and snaps over the bushing extensions on the motor can and cap. The worms on the shaft then extend into openings in the bottom of the frame. The trucks are retained by plates mounted on the frame at each end with slots in them to engage bosses which extend from each side of the truck gearboxes. The left side plate at each end is insulated from the frame with a plastic spacer between it and the frame. A single screw through both plates and the frame hold them in place with an insulating washer on the left side.Wheel wipers are mounted on the gearboxes in the boss area and make contact with both the inner surface of each wheel and the retainer plates which gets current that far. Wires soldered to lugs under the left plate mounting screws carry current to the motor brush holder on the left (hot) side and the right (ground) brush holder has a flat spring which contacts the motor can and the can is grounded through the motor retainer. Because the right side truck retainer plates are also grounded to the frame, this completes the circuit. Actually, the wiring from the left side of the frame could go to either the right or left side of the motor depending on how the motor cap was installed in the factory since this would determine on which side the ground contact would be. In a departure from the past Rivarossi engines, there are no plastic traction tires used on this locomotive, Thus all eight wheels contribute to current collection with some sacrifice in pulling capacity. This little loco will still pull about 20 cars on level track!

This model was first produced by Rivarossi for Atlas in 1971. The trucks are marked 'Made in Italy' with a Rivarossi logo and an Atlas logo. The motor is visible from below on the powered cow. On the dummy calf, a large hollow can be seen from the bottom of the model, corresponding to the missing motor.

After Atlas stopped ordering them ca. 1977, Rivarossi continued selling them with its own brand and reference (#91xx) and released one additional paint scheme (SP Black Widow) in 1980. Con-Cor also began importing the Rivarossi model. On this model, the trucks are marked 'Made in Italy' with a Rivarossi logo only.

The Rivarossi/Con-Cor version was available powered or unpowered, for both the cow and the calf.

The boxes can be labeled with a Rivarossi stock number on one end and a Con-Cor stock number on the other end, sometimes printed on a Rivarossi label.

Models not in Rivarossi catalog, so only sold by Con-Cor, may still show a Rivarossi stock number, corresponding to the type of chassis - #9288 (dummy calf) or #9289 (dummy cow) or #9290 (powered cow) - on one side and a Con-Cor stock number on the other side. The Con-Cor number was on a sticker which tended to detach with age, leaving only the printed Rivarossi number. Hence many classifieds are using the non-distinctive Rivarossi number 9288 or 9289 or 9890.

At a certain point ca. 1985, apparently dissatisfied with the mechanisms made by Rivarossi, Con-Cor had Kato design a new, more reliable, mechanism but continued use of the Rivarossi shell. This new Kato/Rivarossi hybrid was produced until 1989. The change of mechanism only applied to the 'cow' powered unit; the 'calf' dummy unit continued to be fully made by Rivarossi. On the powered cow, the trucks are marked '17712/Made in Japan' with Kato logo and the fuel tank is marked 'Con-Cor' on the bottom.

In 1996, Arnold/Rivarossi re-released the same model with yet another new mechanism and a few improvements of the shell (thinner handrails and tank details). On this model, the fuel tank is marked 'Arnold/Made in Germany'. The couplers are truck-mounted.

At this point Con-Cor released a new version of the model this time using a Chinese manufactured mechanism, but with the shell still more or less the same. These Chinese versions were marketed as SW-1200s. The bottom of the trucks is marked '17712/Made in China', without logo.

Con-Cor stopped making their version during the downsizing in 2005 and Arnold stopped producing theirs in 2006 with the bankruptcy.

The model was designed from early EMD drawings for the SW1500 prototype, that were quite similar to the SW1200 drawings. Eventually the final SW1500 prototype was released with significant changes to the early drawing. So though the model is sold as a SW1500, it is actually closer to a SW1200 than to a SW1500. Moreover, if a cow-calf version of the SW1200 (TR12) was offered in the catalog, it was actually never purchased. No cow-calf version of the SW1500 was ever envisaged.

Review Courtesy of Doug Gosha: The Rivarossi model is a plastic shell and separate walkway molding over a zamac frame. There is an additional weight that fits into the cab portion of the shell. The same basic Rivarossi motor is used as in their other A1G locomotives but in a quite different configuration. In this case, the motor has a double-ended shaft with a worm on each end. Due to considerable space limitations in this small chassis, the worm diameters are much smaller than on the other Rivarossi A1G locos. The motor is kind of suspended under the zamac frame in an opening in the center with a spring sheet metal retainer that passes through holes in the top of the frame and snaps over the bushing extensions on the motor can and cap. The worms on the shaft then extend into openings in the bottom of the frame. The trucks are retained by plates mounted on the frame at each end with slots in them to engage bosses which extend from each side of the truck gearboxes. The left side plate at each end is insulated from the frame with a plastic spacer between it and the frame. A single screw through both plates and the frame hold them in place with an insulating washer on the left side.Wheel wipers are mounted on the gearboxes in the boss area and make contact with both the inner surface of each wheel and the retainer plates which gets current that far. Wires soldered to lugs under the left plate mounting screws carry current to the motor brush holder on the left (hot) side and the right (ground) brush holder has a flat spring which contacts the motor can and the can is grounded through the motor retainer. Because the right side truck retainer plates are also grounded to the frame, this completes the circuit. Actually, the wiring from the left side of the frame could go to either the right or left side of the motor depending on how the motor cap was installed in the factory since this would determine on which side the ground contact would be. In a departure from the past Rivarossi engines, there are no plastic traction tires used on this locomotive, Thus all eight wheels contribute to current collection with some sacrifice in pulling capacity. This little loco will still pull about 20 cars on level track!

DCC Information: No provision for DCC, except on the Arnold version.

Prototype History: The EMD SW1500 was a 1,500 hp (1,119 kW) Diesel-electric locomotive intended for switching service and built by General Motors' Electro-Motive Division between June 1966 and January 1974. 808 examples were constructed. It was closely related to the less powerful EMD SW1000 model, forming a line of switchers powered by the new EMD 645 engine. The SW1500 replaced the SW1200 in the EMD product line, and was in turn replaced by the MP15DC.

The SW1500 was a substantially bulkier locomotive than the SW1200, with a much bulkier frame, larger cab and bigger hood. In many respects it was approaching a road switcher in abilities. While the SW1500 came as standard with AAR switcher trucks, the majority of them were delivered with the optional Flexicoil trucks which permitted speeds up to 60 mph (100 km/h). The SW1500 was, in fact, often operated as a road-switcher for branchline service, and continues in this role today.

From Wikipedia

The SW1500 was a substantially bulkier locomotive than the SW1200, with a much bulkier frame, larger cab and bigger hood. In many respects it was approaching a road switcher in abilities. While the SW1500 came as standard with AAR switcher trucks, the majority of them were delivered with the optional Flexicoil trucks which permitted speeds up to 60 mph (100 km/h). The SW1500 was, in fact, often operated as a road-switcher for branchline service, and continues in this role today.

From Wikipedia

Road Name History: The Union Pacific Railroad (reporting mark UP) is a freight hauling railroad that operates 8,500 locomotives over 32,100 route-miles in 23 states west of Chicago, Illinois and New Orleans, Louisiana. The Union Pacific Railroad network is the largest in the United States and employs 42,600 people. It is also one of the world's largest transportation companies.

Union Pacific Railroad is the principal operating company of Union Pacific Corporation (NYSE: UNP); both are headquartered in Omaha, Nebraska. Over the years Union Pacific Corporation has grown by acquiring other railroads, notably the Missouri Pacific, Chicago & North Western, Western Pacific, Missouri-Kansas-Texas, and the Southern Pacific (including the Denver & Rio Grande Western).

Union Pacific Corporation's main competitor is the BNSF Railway, the nation's second largest freight railroad, which also primarily services the Continental U.S. west of the Mississippi River. Together, the two railroads have a duopoly on all transcontinental freight rail lines in the U.S.

Read more on Wikipedia and on Union Pacific official website.

Union Pacific Railroad is the principal operating company of Union Pacific Corporation (NYSE: UNP); both are headquartered in Omaha, Nebraska. Over the years Union Pacific Corporation has grown by acquiring other railroads, notably the Missouri Pacific, Chicago & North Western, Western Pacific, Missouri-Kansas-Texas, and the Southern Pacific (including the Denver & Rio Grande Western).

Union Pacific Corporation's main competitor is the BNSF Railway, the nation's second largest freight railroad, which also primarily services the Continental U.S. west of the Mississippi River. Together, the two railroads have a duopoly on all transcontinental freight rail lines in the U.S.

Read more on Wikipedia and on Union Pacific official website.

Brand/Importer Information:  Founded in 1906 by Karl Arnold in Nuernberg, K. Arnold & Co. began its life producing tin toys and related items. They produced an extensive line of model ships, doll house items and other toys. In 1935, K. Arnold & Co. hired Max Ernst as their managing director. Ernst, not to be confused with the German realist artist of the same name, was a significant factor in the future of Arnold.

Founded in 1906 by Karl Arnold in Nuernberg, K. Arnold & Co. began its life producing tin toys and related items. They produced an extensive line of model ships, doll house items and other toys. In 1935, K. Arnold & Co. hired Max Ernst as their managing director. Ernst, not to be confused with the German realist artist of the same name, was a significant factor in the future of Arnold.

There are several distinct phases of Arnold's model train production. In the period of 1960 - 1962, Arnold marketed the Arnold Rapido 200 product line; this line was very crude yet it also was a sensation because of its much smaller size than TT.

The next phase was from 1963-1967, when the rapido product line begins to swing toward scale representations of the trains. It is during this period that the "Rapido Coupler" comes into production, beginning its widespread use by all model train manufacturers in N-Scale. It was in 1964 that the term "N-Scale" came into use. Between 1968 and 1970, rapido line of trains reached maturity, notably with its turntable and roundhouse. Arnold entered into a business relationship with the U.S. company Revell around 1968, beginning the marketing of Revell Rapido model trains. This relationship was marked by the beginning of production of more accurate North American prototype models by Arnold. This relationship continued for several years, ending in the late 1960s or early 1970s. Arnold continued their expanded production, with new models until the early 1990s.

On Max Ernst's 1976 retirement, Arnold employed perhaps 200 to 250 people, using three facilities in the Nurnberg area. The Company continued under family control until 1995, when Arnold went into bankruptcy and was sold to Rivarossi of Italy. Rivarossi, in turn, also went bankrupt, leading to the sale of all assets to Hornby of the United Kingdom. Production is carried out in China.

There are several distinct phases of Arnold's model train production. In the period of 1960 - 1962, Arnold marketed the Arnold Rapido 200 product line; this line was very crude yet it also was a sensation because of its much smaller size than TT.

The next phase was from 1963-1967, when the rapido product line begins to swing toward scale representations of the trains. It is during this period that the "Rapido Coupler" comes into production, beginning its widespread use by all model train manufacturers in N-Scale. It was in 1964 that the term "N-Scale" came into use. Between 1968 and 1970, rapido line of trains reached maturity, notably with its turntable and roundhouse. Arnold entered into a business relationship with the U.S. company Revell around 1968, beginning the marketing of Revell Rapido model trains. This relationship was marked by the beginning of production of more accurate North American prototype models by Arnold. This relationship continued for several years, ending in the late 1960s or early 1970s. Arnold continued their expanded production, with new models until the early 1990s.

On Max Ernst's 1976 retirement, Arnold employed perhaps 200 to 250 people, using three facilities in the Nurnberg area. The Company continued under family control until 1995, when Arnold went into bankruptcy and was sold to Rivarossi of Italy. Rivarossi, in turn, also went bankrupt, leading to the sale of all assets to Hornby of the United Kingdom. Production is carried out in China.

Item created by: Alain LM on 2022-01-30 12:34:44. Last edited by Alain LM on 2022-01-30 12:34:45

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.