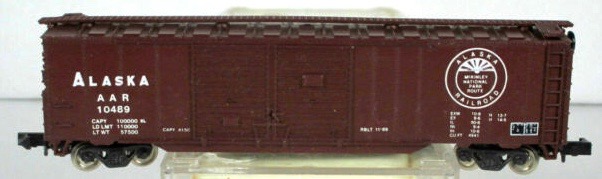

Model Information: These cars were made for Con-Cor by Kato for the initial run. Later releases were manufactured in Con-Cor's Chicago facility.

Prototype History: A refrigerator car (or “reefer”) is a refrigerated boxcar (US) or van (UIC), a piece of railroad rolling stock designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple insulated boxcars and ventilated boxcars (commonly used for transporting fruit), neither of which are fitted with cooling apparatus. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or utilize carbon dioxide (either as dry ice, or in liquid form) as a cooling agent. Milk cars (and other types of “express” reefers) may or may not include a cooling system, but are equipped with high-speed trucks and other modifications that allow them to travel with passenger trains.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

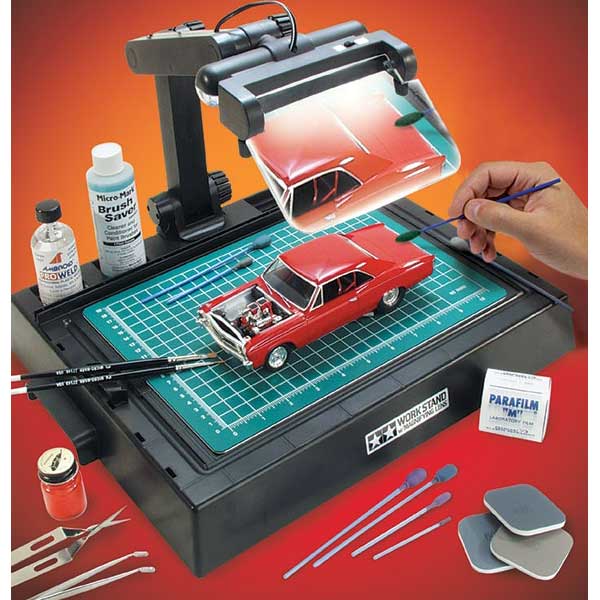

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: CNW400 on 2021-09-18 22:19:00

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.