Model Information: This model was first imported by Aurora from Minitrix in the early 1970s. Later after Aurora ceased their N Scale business, Con-Cor resumed the importing under their own brand name. Like most other models they initially imported , Con-Cor likely acquired the rights to produce their own version in their US factory. Later, production was moved to China. Early versions featured deep flange Nickel Silver wheelsets with Rapido Couplers. More recent Chinese imports are fitted with Micro-Trains trucks and couplers.

Prototype History: GATX introduced the Tank Train series in the 1970s. The Tank Train is a string of interconnected tank cars with flexible hoses, developed exclusively by GATX’s research and development team, allows for quick loading and unloading of commodities including crude petroleum oil, benzene, light fuel oil and phosphoric acid.

The GATX TankTrain™ System can be loaded or unloaded at a rate of 3,000 gallons per minute. A five-car string loads in just 90 minutes, while a 90-car train takes less than five hours. The cars come in the following configurations:

The GATX TankTrain™ System can be loaded or unloaded at a rate of 3,000 gallons per minute. A five-car string loads in just 90 minutes, while a 90-car train takes less than five hours. The cars come in the following configurations:

- 14,500 GS, Acid Phosphoric Acid

- 20,000 Exterior Coiled Fuel Oil, Crude Oil

- 26,000 Coiled, Non-Coiled Various chemicals

- 30,000 Non-Coiled Gasoline

- 33,500 High Pressure LPG

Road Name History:  General American's TankTrain system of interconnecting tank cars provides shippers with a quick and cost-effective method of moving large volumes of bulk liquids. The TankTrain system consists of an entire string of cars that can be loaded or unloaded from a single System connection. The last car in each set (of 12 cars) is left 3/4 full. Then nitrogen gas (non-flammable, non-toxic) is used to purge the loading lines of any remaining oil which fills the last car.

General American's TankTrain system of interconnecting tank cars provides shippers with a quick and cost-effective method of moving large volumes of bulk liquids. The TankTrain system consists of an entire string of cars that can be loaded or unloaded from a single System connection. The last car in each set (of 12 cars) is left 3/4 full. Then nitrogen gas (non-flammable, non-toxic) is used to purge the loading lines of any remaining oil which fills the last car.

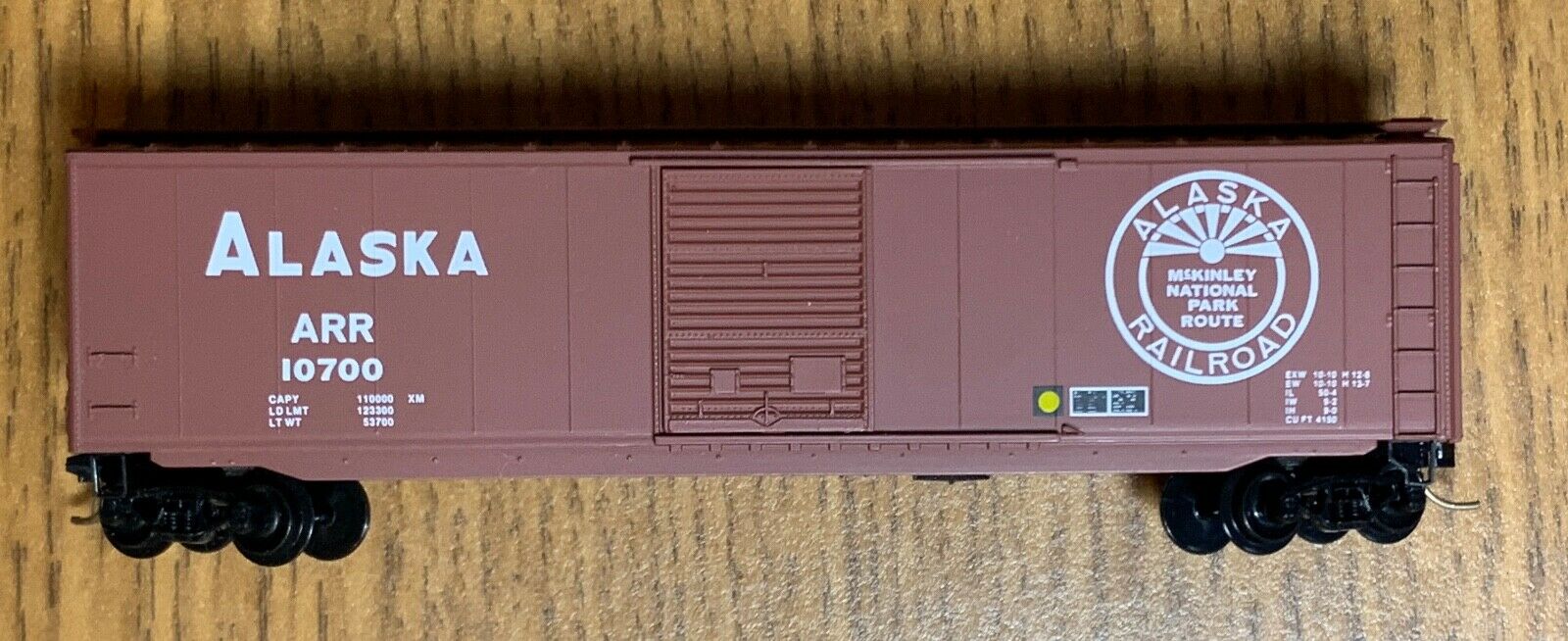

The TankTrain System was first tested by the Alaska Railroad. The ARR purchased two sets of three that were linked together. They didn't stay that way though and eventually wound up as individual cars. Some ARR crew members felt they were more bother than they were worth. The cars had to be kept turned in a certain direction which wasn't always operationally easy. If one car was Bad Ordered then the whole string had to go in the shop. The ARR ceased using them in the late 1970s and they were all shipped to the lower 48. A much updated version of the TankTrain was later fielded for the Southern Pacific "Oilcan" that went from central California, over Tehachapi Pass, to Los Angeles. Later, the run went from Mojave to L.A.,

The TankTrain System was first tested by the Alaska Railroad. The ARR purchased two sets of three that were linked together. They didn't stay that way though and eventually wound up as individual cars. Some ARR crew members felt they were more bother than they were worth. The cars had to be kept turned in a certain direction which wasn't always operationally easy. If one car was Bad Ordered then the whole string had to go in the shop. The ARR ceased using them in the late 1970s and they were all shipped to the lower 48. A much updated version of the TankTrain was later fielded for the Southern Pacific "Oilcan" that went from central California, over Tehachapi Pass, to Los Angeles. Later, the run went from Mojave to L.A.,

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: CNW400 on 2020-08-25 12:38:47. Last edited by CNW400 on 2021-08-23 22:00:42

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.