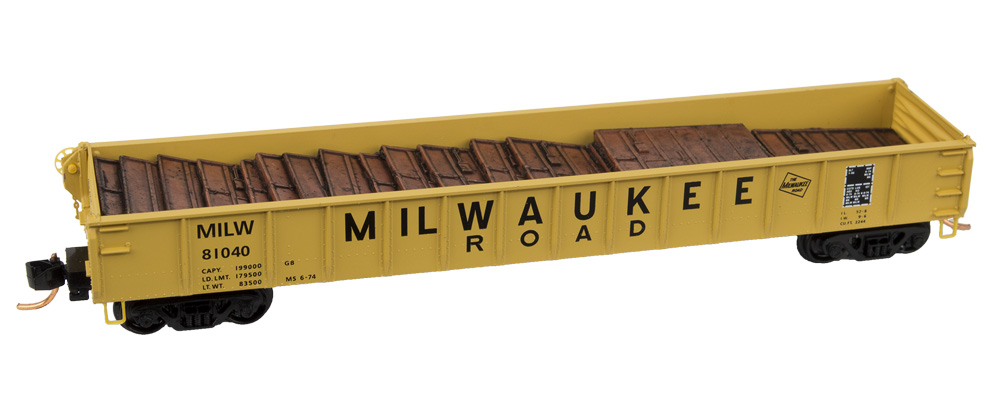

Specific Item Information: In the early Sixties, Evans Products saw a need for specialized cars to transport coiled steel. The existing cars at the time were often 70-ton specially equipped mill gondolas. The new commodity-specific coil-steel car were built with a 100-ton capacity using a trough frame and body. The early designs were refined during the 1960s and eventually Evans adopted a 48-foot length as standard. Production lasted well into the 1970s. The Atlas 48-foot coil steel car is based on the Evans design of 1967 as well as being a close stand-in for the 1970s cars.

Features:

Features:

- Die-cast body

- Crisp painting and lettering

- Two removable rounded hoods with stacking frames

- Detailed wood lined trough floor

Model Information: Walthers introduced this model in the 1990s. It was part of the series of Chinese-made models that was developed by Walthers to replace the European models they had been importing. This is the first major release of a steel coil car. Later on, Atlas and Red Caboose would produce their own versions. This model features truck-mounted Rapido couplers and low-profile plastic wheelsets.

Prototype History: The increased volume of coiled steel transportation gave rise to a new purpose-built freight car. Previously rolls of coiled-steel had generally traveled in specially equipped gondola cars. In the 1960s a lighter type of car emerged specifically for hauling coils of steel in an integral trough. The car type gained popularity and eventually over 17,000 cars were built. One common model was the 48 foot design from Evans.

The new commodity-specific coil-steel car were built with a 100-ton capacity using a trough frame and body. The early designs were refined during the 1960s and eventually Evans adopted a 48-foot length as standard. Production lasted well into the 1970s.

The new commodity-specific coil-steel car were built with a 100-ton capacity using a trough frame and body. The early designs were refined during the 1960s and eventually Evans adopted a 48-foot length as standard. Production lasted well into the 1970s.

Road Name History: The IHB is an independent railroad which is jointly owned by Conrail Shared Assets Operations (51%) and Canadian Pacific Railway (49%). These shareholders trace their ownership stake in IHB to previous mergers and acquisitions in the railroad industry. This came from Conrail, which had owned a 51% controlling interest. Conrail's ownership is traced back to the Penn Central Transportation Company and prior to that, the New York Central Railroad and Pennsylvania Railroad. Canadian Pacific's ownership is through its subsidiary, the Soo Line Railroad, which had inherited it from the Chicago, Milwaukee, St. Paul and Pacific Railroad.

The line comprises 320 miles (510 km) of track?30 miles of single mainline track, 24 miles (39 km) of double-main track and 266 miles (428 km) of additional yard and side track?starting northwest of Chicago in Franklin Park, Illinois, traveling southeast around the city to its headquarters in Hammond, Indiana.

The line's largest yard, [Blue Island] is located in Riverdale, Illinois with other yards in Burnham, Calumet City, Alsip, Argo, LaGrange, Rose and Franklin Park. In [Indiana] Whiting, Hammond, Michigan Ave, Lake Front in East Chicago. The Gibson Yard located in [Hammond], is arguably the largest auto-switching operation in the United States.

Throughout the 1970s and 1990s to the present, Indiana Harbor Belt operated an extensive interlocking tower system including: East End, Osbourne, Calumet, State Line, Gibson, Stewart Avenue, Graselli, 55th Street and Argo towers with switch tenders at North Harvey and Columbia Avenue in Hammond. They later took over State Line tower from the Chicago and Western Indiana Railroad.

From Wikipedia

The line comprises 320 miles (510 km) of track?30 miles of single mainline track, 24 miles (39 km) of double-main track and 266 miles (428 km) of additional yard and side track?starting northwest of Chicago in Franklin Park, Illinois, traveling southeast around the city to its headquarters in Hammond, Indiana.

The line's largest yard, [Blue Island] is located in Riverdale, Illinois with other yards in Burnham, Calumet City, Alsip, Argo, LaGrange, Rose and Franklin Park. In [Indiana] Whiting, Hammond, Michigan Ave, Lake Front in East Chicago. The Gibson Yard located in [Hammond], is arguably the largest auto-switching operation in the United States.

Throughout the 1970s and 1990s to the present, Indiana Harbor Belt operated an extensive interlocking tower system including: East End, Osbourne, Calumet, State Line, Gibson, Stewart Avenue, Graselli, 55th Street and Argo towers with switch tenders at North Harvey and Columbia Avenue in Hammond. They later took over State Line tower from the Chicago and Western Indiana Railroad.

From Wikipedia

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Manufacturer Information: 'Atlas Model Railroad' represents the New Jersey manufacturing facility for Atlas brand model railroad products. Atlas also imported European made models in their early years and those items will be noted as having manufacturers set appropriately. In the 1990s Atlas moved all their toolings to China.

Item created by: CNW400 on 2020-08-18 22:44:13. Last edited by CMK on 2021-09-09 07:37:53

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.