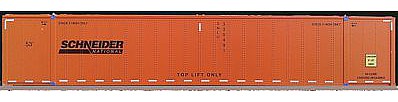

Prototype History: An intermodal container is a large standardized shipping container, designed and built for intermodal freight transport, meaning these containers can be used across different modes of transport – from ship to rail to truck – without unloading and reloading their cargo. Intermodal containers are primarily used to store and transport materials and products efficiently and securely in the global containerized intermodal freight transport system, but smaller numbers are in regional use as well. These containers are known under a number of names, such as simply container, cargo or freight container, ISO container, shipping, sea or ocean container, container van or (Conex) box, sea or c can.

53' Containers are generally used only in North American domestic transportation and hence not usually seen on container ships. They are, however, extremely popular in North America due to the increased capacity and efficiency when compared to their 40 foot, ocean-going cousins. Also, since they are not typically used on ships, they have reduced bracing and structural integrity making them cheaper to produce. As result, in 2013, APL, a major logisitics firm, officially ceased support of ocean going transport of these units for simple lack of demand combined with specialized facilities for loading and storage of these units.

Special refrigerated containers, commonly called reefers, can control temperatures, allowing everything from meat, fruit, vegetables and dairy products, to chemicals and pharmaceuticals to travel across the world. Cryogenics may sound like a science of the future but reefer containers get pretty close today. Special super-freeze reefers can keep goods frozen at temperatures as low as -60 degrees C. But other reefers can preserve goods at warmer temperatures if that is necessary. De-humidification systems are able to ensure optimal humidity inside reefer containers. Some reefers also allow the atmosphere in the container to be controlled so for example, bananas can be shipped between continents without turning brown. Even fresh flowers can remain fresh in reefer containers while they are travelling many miles over several days. It is because of reefer containers, that grocery stores are able to stock and sell all kinds of fresh produce all year round.

Some of this text is from Wikipedia

53' Containers are generally used only in North American domestic transportation and hence not usually seen on container ships. They are, however, extremely popular in North America due to the increased capacity and efficiency when compared to their 40 foot, ocean-going cousins. Also, since they are not typically used on ships, they have reduced bracing and structural integrity making them cheaper to produce. As result, in 2013, APL, a major logisitics firm, officially ceased support of ocean going transport of these units for simple lack of demand combined with specialized facilities for loading and storage of these units.

Special refrigerated containers, commonly called reefers, can control temperatures, allowing everything from meat, fruit, vegetables and dairy products, to chemicals and pharmaceuticals to travel across the world. Cryogenics may sound like a science of the future but reefer containers get pretty close today. Special super-freeze reefers can keep goods frozen at temperatures as low as -60 degrees C. But other reefers can preserve goods at warmer temperatures if that is necessary. De-humidification systems are able to ensure optimal humidity inside reefer containers. Some reefers also allow the atmosphere in the container to be controlled so for example, bananas can be shipped between continents without turning brown. Even fresh flowers can remain fresh in reefer containers while they are travelling many miles over several days. It is because of reefer containers, that grocery stores are able to stock and sell all kinds of fresh produce all year round.

Some of this text is from Wikipedia

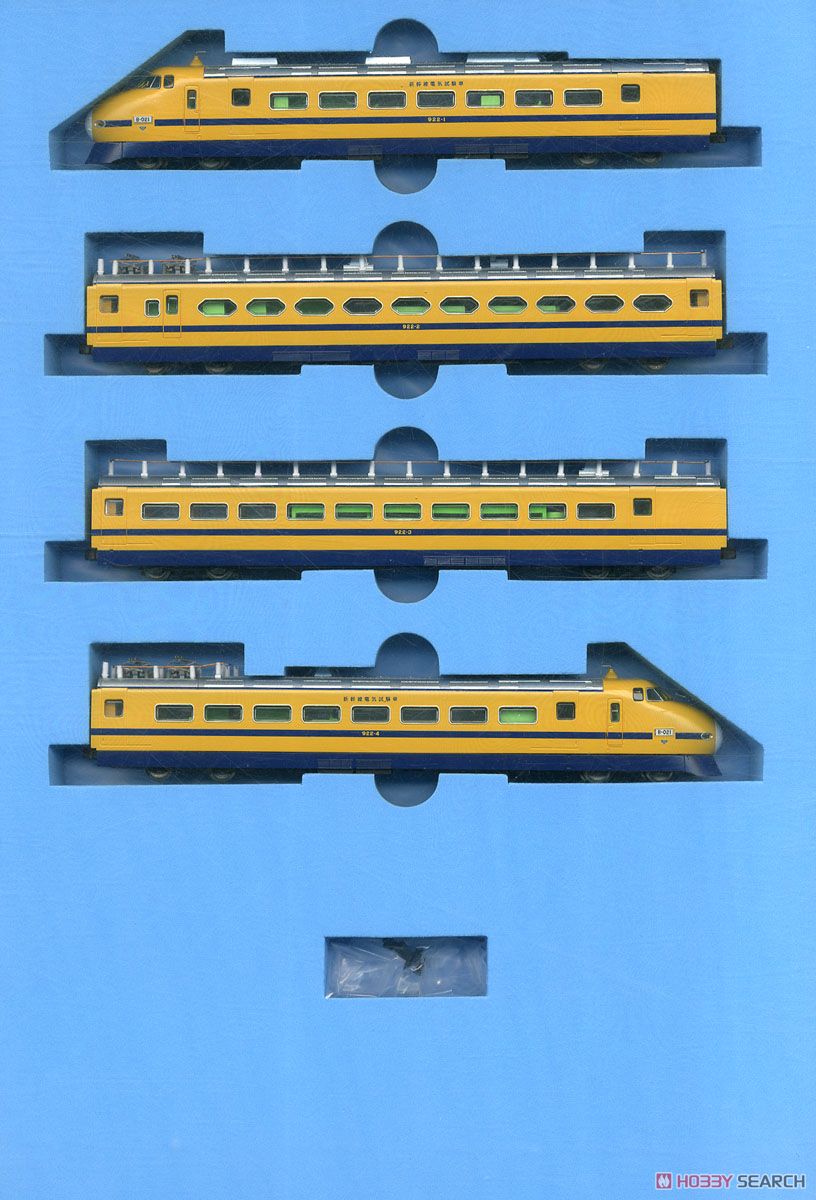

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: CNW400 on 2020-06-22 09:06:08. Last edited by CNW400 on 2020-06-22 09:06:09

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.