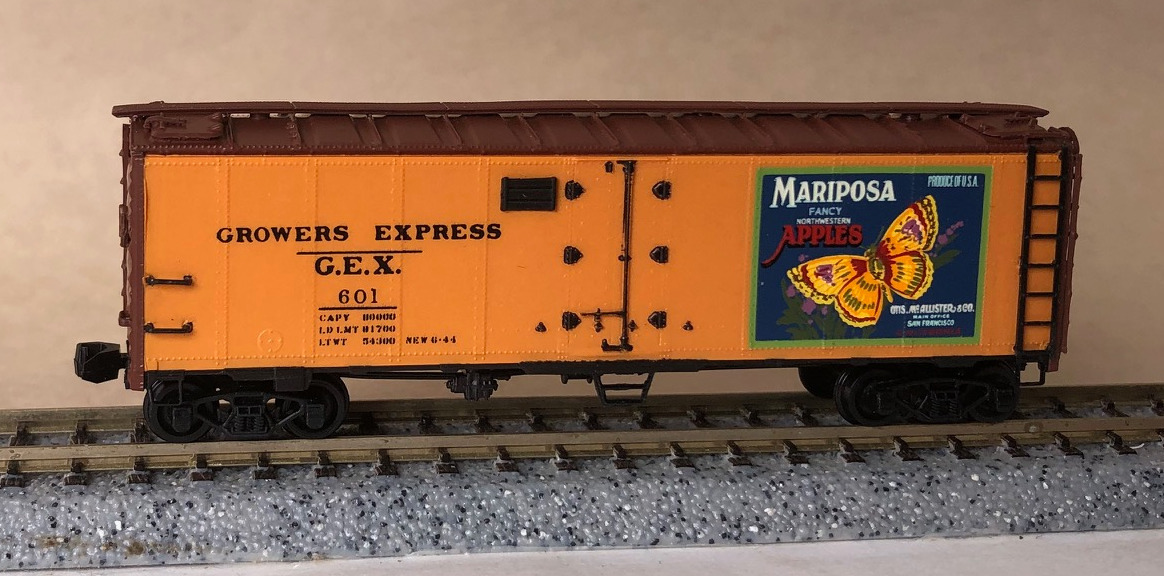

Prototype History: The purpose of a mechanical reefer is to keep perishable items cold. Early reefers were of all wood construction and used ice for cooling. By the 1940s, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Fifty foot mechanical reefers date back to at least the late 50s / early 60s.

The mechanical reefers could keep a more regular temperature, and often times colder than what the ice bunker cars were capable of. Initially mechanical reefers were used primarily in frozen food service. This would soon change as mechanical refrigeration began to replace ice-based systems. Soon after, mechanical refrigeration units replaced the “armies” of personnel required to re-ice the cars.

The first record of a 50' mechanical refrigerator car with a 6' plug door appears in the October 1954 Official Railway Equipment as with reporting marks FGEX 1000 - 1100. The January 1958 Official Railway Equipment Register lists over 600 of these cars. They appear with road numbers between 1000 and 1600. The build dates will fall between these two dates.

They were first acquired for orange juice service out of Florida. Similar cars were owned by WFEX and BREX. All were used in pool service with one another, depending upon the season. You can find a remaining prototype preserved in the NC Transportation Museum in Spencer, NC.

The mechanical reefers could keep a more regular temperature, and often times colder than what the ice bunker cars were capable of. Initially mechanical reefers were used primarily in frozen food service. This would soon change as mechanical refrigeration began to replace ice-based systems. Soon after, mechanical refrigeration units replaced the “armies” of personnel required to re-ice the cars.

The first record of a 50' mechanical refrigerator car with a 6' plug door appears in the October 1954 Official Railway Equipment as with reporting marks FGEX 1000 - 1100. The January 1958 Official Railway Equipment Register lists over 600 of these cars. They appear with road numbers between 1000 and 1600. The build dates will fall between these two dates.

They were first acquired for orange juice service out of Florida. Similar cars were owned by WFEX and BREX. All were used in pool service with one another, depending upon the season. You can find a remaining prototype preserved in the NC Transportation Museum in Spencer, NC.

Road Name History: The Theodore Hamm Brewing Company was established in 1865 when , a German immigrant Theodore Hamm (1825-1903) inherited the Excelsior Brewery from his friend and business associate A. F. Keller, who had perished in California seeking his fortune in the gold fields. Unable to finance the venture himself, Keller had entered into a partnership with Hamm to secure funding. Upon Keller's death, Hamm inherited the small brewery and flour mill in the east side wilderness of St. Paul, Minnesota. Keller had constructed his brewery in 1860 over artesian wells in a section of the Phalen Creek valley in St. Paul known as Swede Hollow. Hamm, a butcher by trade and local salon owner, first hired Jacob Schmidt as a brew master. Jacob Schmidt remained with the company until the early 1880s, becoming a close family friend of the Hamms. Jacob Schmidt left the company after an argument ensued over Louise Hamm's disciplinary actions to Schmidt's daughter, Marie. By 1884, Schmidt was a partner at the North Star Brewery not far from Hamm's brewery. By 1899 he had established his own brewery on the site of the former Stalhmann Brewery site. In need of a new brewmaster, Hamm hired Christopher Figge who would start a tradition of three generations of Hamm's Brewmasters, with his son William and grandson William II taking the position. By the 1880s, the Theodore Hamm Brewing Company was reportedly the second largest in Minnesota.

During Prohibition, the company survived by producing soft drinks and other food products, enabling it to expand rapidly through acquisitions after the repeal of Prohibition in 1933. From 1933 until 1965 Hamm's saw much success; much of this can be attributed to William C. Figge Jr. taking over as President in 1951. Figge expanded the Hamm's brand into a national entity with breweries in St. Paul, Minnesota; Los Angeles, California; San Francisco, California; Baltimore, Maryland; and Houston, Texas. The latter two were short-lived and closed soon after they opened. As the company celebrated its 100th anniversary, the family decided to sell the brewery and leave the ever more competitive brewing industry to focus on its other ventures like its successful real estate company.

From Wikipedia

During Prohibition, the company survived by producing soft drinks and other food products, enabling it to expand rapidly through acquisitions after the repeal of Prohibition in 1933. From 1933 until 1965 Hamm's saw much success; much of this can be attributed to William C. Figge Jr. taking over as President in 1951. Figge expanded the Hamm's brand into a national entity with breweries in St. Paul, Minnesota; Los Angeles, California; San Francisco, California; Baltimore, Maryland; and Houston, Texas. The latter two were short-lived and closed soon after they opened. As the company celebrated its 100th anniversary, the family decided to sell the brewery and leave the ever more competitive brewing industry to focus on its other ventures like its successful real estate company.

From Wikipedia

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: CNW400 on 2020-01-23 08:36:52. Last edited by CNW400 on 2020-06-25 12:30:20

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.