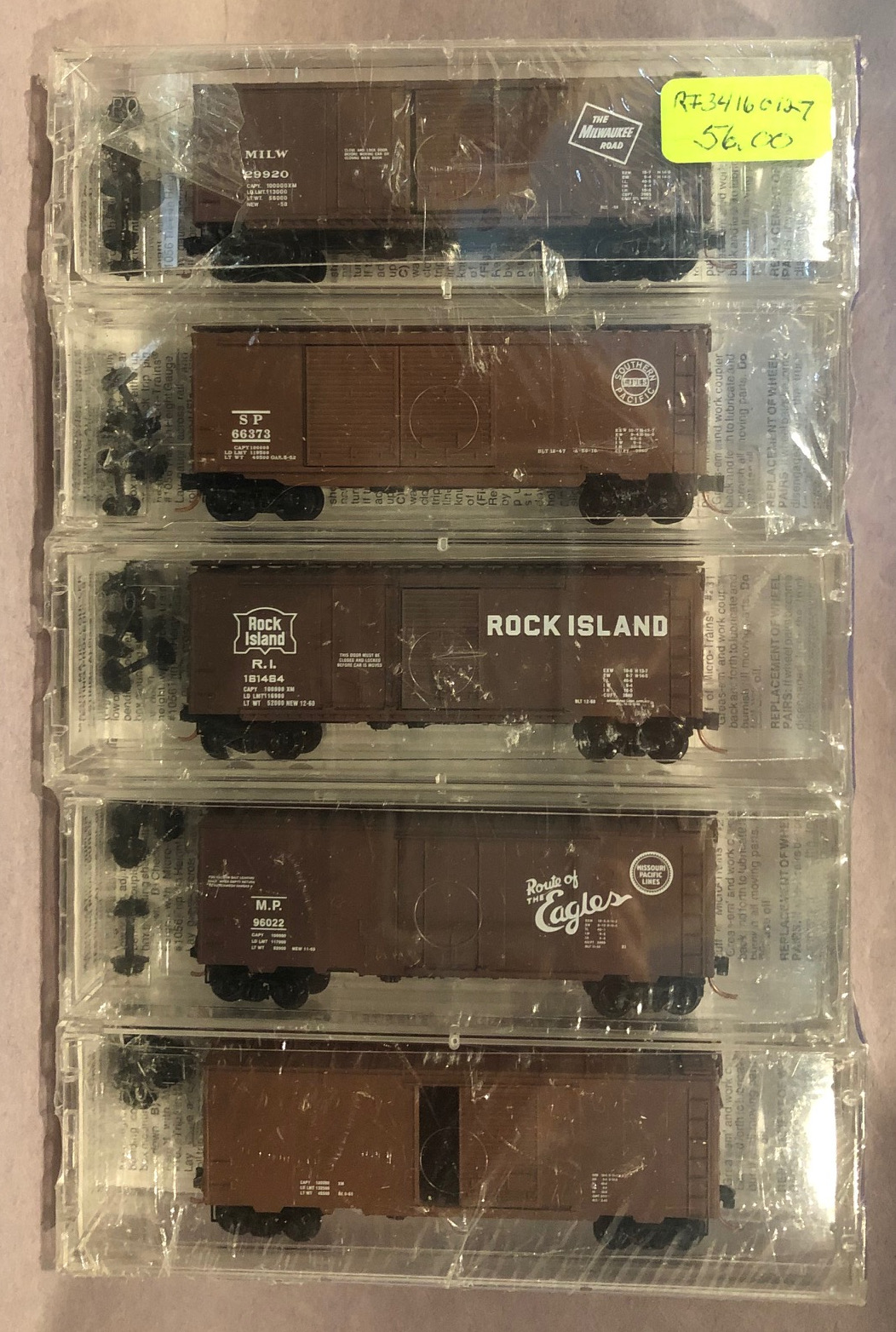

Model Information: These kits are molded in gray polystyrene. Trucks and Decals are not included.

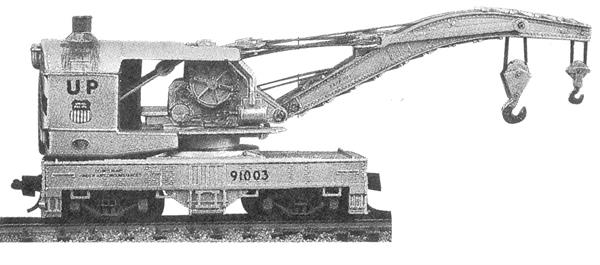

Prototype History: A complete wreck train consisted of a locomotive, a wreck crane, tool cars, and enough bunk and cook cars for personnel required for a particular wreck. Wreck cranes and tool cars were often stationed at strategic points along the railway line. Division terminals were considered strategic points because locomotives and engine, train, and wreck car crews were always available on call. Wreck train equipment had to be prepared for immediate movement. Ties, rails, spikes, and other repair materials are stockpiled at various points. An emergency supply of such items were also loaded in suitable cars and held with each wrecker as part of the wreck train.

A wreck train, or “relief train” as the railroads preferred to call them used a huge piece of equipment built by companies such as Brownhoist. A typical wrecking crane was powered by twin diesel engines with a 500,000 pound capacity. This crane could easily lift an entire Reading T-1 steam locomotive. At 191-tons, it is a very heavy piece of equipment. It easily outweighs an Alco C630!

A wreck train, or “relief train” as the railroads preferred to call them used a huge piece of equipment built by companies such as Brownhoist. A typical wrecking crane was powered by twin diesel engines with a 500,000 pound capacity. This crane could easily lift an entire Reading T-1 steam locomotive. At 191-tons, it is a very heavy piece of equipment. It easily outweighs an Alco C630!

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

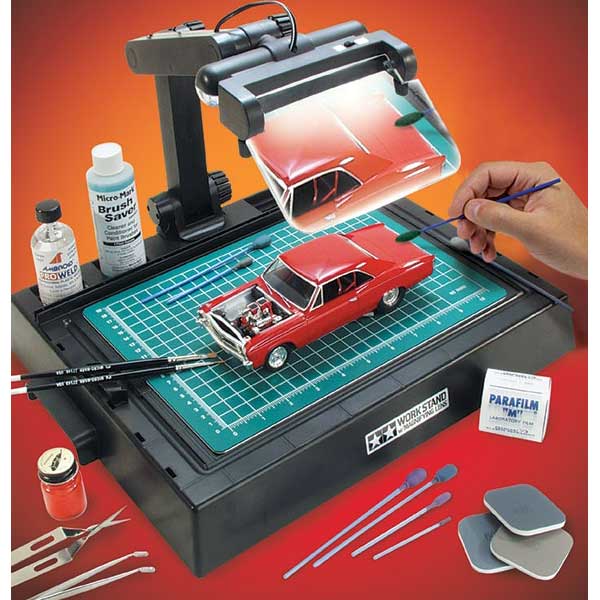

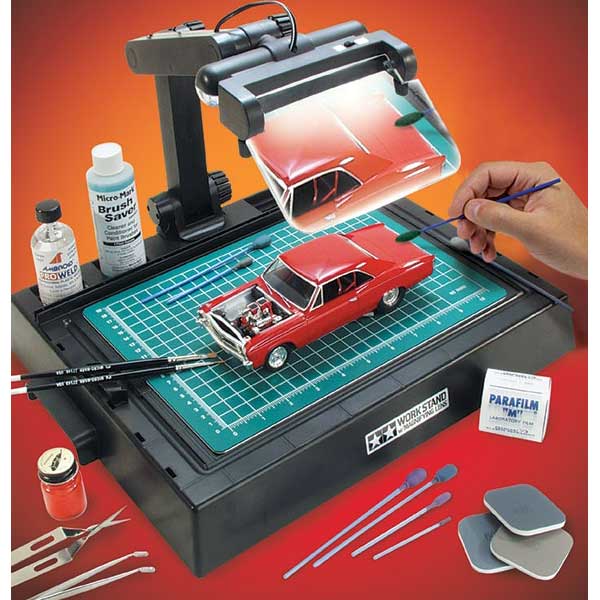

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: We bring together the best of two worlds, combining the fun and reward of fine model building with the rapidly growing interest in prototype railroading, freight cars and structures, in particular. The preservation of prototype history in miniature. The key personnel at TICHY TRAIN GROUP are active model railroaders with over fifty-five years of collective experience in the hobby.

Advanced technology and old world craftsmanship combine to produce the finest plastic kits available. Since all aspects of the manufacturing procedure done in our own plant, we have complete control over the quality of out product. Our extensive research library helps us to ensure the accuracy of every detail. Our fully equipped toolroom enables us to translate the design into permanent metal tooling, using cutters ranging from three inches in diameter to as small as a human hair. Each kit may represent several thousand hours of design, engineering, template and model making, engraving and hand polishing. However, this painstaking attention to detail makes the final product speak for itself.

Our kits conform to all applicable NMRA standards and recommended practices. They accept Kadee® #5 or equivalent style couplers (not included) and we provide special molded washers to allow correct coupler height with other trucks.

Tichy is located in Alamance, North Carolina.

Advanced technology and old world craftsmanship combine to produce the finest plastic kits available. Since all aspects of the manufacturing procedure done in our own plant, we have complete control over the quality of out product. Our extensive research library helps us to ensure the accuracy of every detail. Our fully equipped toolroom enables us to translate the design into permanent metal tooling, using cutters ranging from three inches in diameter to as small as a human hair. Each kit may represent several thousand hours of design, engineering, template and model making, engraving and hand polishing. However, this painstaking attention to detail makes the final product speak for itself.

Our kits conform to all applicable NMRA standards and recommended practices. They accept Kadee® #5 or equivalent style couplers (not included) and we provide special molded washers to allow correct coupler height with other trucks.

Tichy is located in Alamance, North Carolina.

Item created by: gdm on 2018-10-09 07:14:54

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.