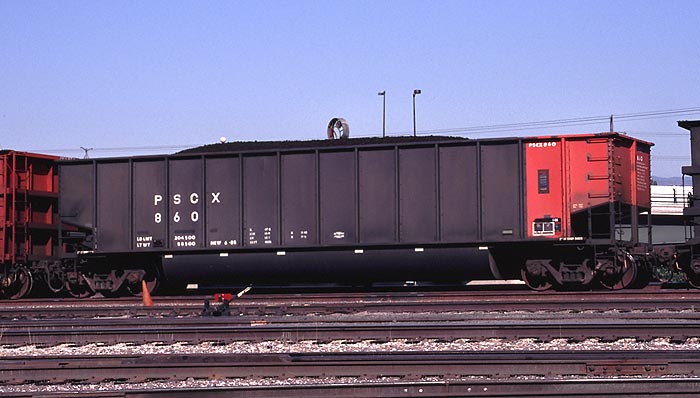

Prototype History: The Powder River Basin is a hot bed of coal activity. There is more coal run out of this one area than all other areas of the US combined. It is an amazing railfan opportunity, as there is train after train after train of 100+ cars leaving the basin for power plants all over the country. The trains pull through a mine and are flow loaded, with the train continuously moving at very slow speed, while the loader operator drops up to 110 tons of coal into each aluminum car. It is an awesome site to see. The flow loader piles the coal into the car, and each load settles to it's own shape. At the other end of the chain, many of the power plants or shipping docks (yes, some of this high quality cleaner burning coal goes overseas, too) unload the cars by rolling them over, while they are still coupled in the train. This is accomplished by use of a rotary coupler, which needs to be oriented correctly in the train in order to work. The orientation is accomplished visually by the unique colored end, or rotary end on the car. You will find these trains anywhere along their route with all of the rotaries lined up in the same direction. Each car is equipped with one rotary coupler, and one fixed coupler (the exceptions are the double rotary cars, which we'll get to in a second), so that the car can be rolled over without uncoupling. The most recent version of the car is constructed of aluminum for weight and strength reasons. The side stakes are a box shape of aluminum, and have distinctive crisp square corners. The earlier version of the car was made in steel, with folded steel "hat section" stiles that were thinner and rounder. Johnstown America is a pioneer in getting the most out of their materials.

When they introduced the revolutionary original all steel construction Bethgon, they started a change in the way railroads thought about coal transportation. With the Coalporter, the revolution continued. Now they are working on even more advanced systems to deliver clean fuel to America's electric plants. With their innovations, the Twin Tub has become one of the dominant coal conveyances in modern railroading. Certainly it is distinctive seeing 105 car unit trains on the rails. The cars on the road today are divided into several types. The railroad trains, like BNSF, and Norfolk Southern, are contract trains. They transport on routes that they have bid for and service with a rotating pool of equipment. The power company trains are owned or leased specifically by a particular power company, and run on a dedicated route from the coal mine to the power plant and back. From time to time, the power plant will require more coal than their owned equipment is capable of carrying, and they will lease or hire additional cars. These may come from a leasing organization (Transisco, Systems Fuels, or First Union), a railroad, or another power plant that may have over capacity. Portland General Electric is a good example of leasable trains. The Portland Rose cars often sit idle when local hydro electric power plants are generating at full capacity. At these times, the cars get leased out to other power companies at favorable rates. It is not unusual to see a train full of Portland Rose cars on it's way to San Antonio or St Louis when the Pacific Northwest has full rivers! The double rotary cars ride next to the locomotives or at any position where the train may need to be pulled in both directions to unload. If the unloader is placed on a stub track, at the end of the line, or on a wye, the loco may be tied onto either end, making it impossible to predict which way to order the cars (rotary first or non-rotary first). In these instances a double rotary is used. They are very distinctive, as whatever color is used to indicate a rotary coupler is visible on both ends. In the case of the PGEX cars, each end is equipped with colored panels and the four color rose.

When they introduced the revolutionary original all steel construction Bethgon, they started a change in the way railroads thought about coal transportation. With the Coalporter, the revolution continued. Now they are working on even more advanced systems to deliver clean fuel to America's electric plants. With their innovations, the Twin Tub has become one of the dominant coal conveyances in modern railroading. Certainly it is distinctive seeing 105 car unit trains on the rails. The cars on the road today are divided into several types. The railroad trains, like BNSF, and Norfolk Southern, are contract trains. They transport on routes that they have bid for and service with a rotating pool of equipment. The power company trains are owned or leased specifically by a particular power company, and run on a dedicated route from the coal mine to the power plant and back. From time to time, the power plant will require more coal than their owned equipment is capable of carrying, and they will lease or hire additional cars. These may come from a leasing organization (Transisco, Systems Fuels, or First Union), a railroad, or another power plant that may have over capacity. Portland General Electric is a good example of leasable trains. The Portland Rose cars often sit idle when local hydro electric power plants are generating at full capacity. At these times, the cars get leased out to other power companies at favorable rates. It is not unusual to see a train full of Portland Rose cars on it's way to San Antonio or St Louis when the Pacific Northwest has full rivers! The double rotary cars ride next to the locomotives or at any position where the train may need to be pulled in both directions to unload. If the unloader is placed on a stub track, at the end of the line, or on a wye, the loco may be tied onto either end, making it impossible to predict which way to order the cars (rotary first or non-rotary first). In these instances a double rotary is used. They are very distinctive, as whatever color is used to indicate a rotary coupler is visible on both ends. In the case of the PGEX cars, each end is equipped with colored panels and the four color rose.

Road Name History:  This operation was born from the 1970 bankruptcy of Penn Central. PC was unable to provide enough locomotives and hoppers that were in good repair to keep the coal moving between the mines in Pennsylvania’s Monongahela region and the DE power plant in Monroe, Michigan. So, Detroit Edison acquired a fleet of their own locomotives, including SD40’s and U30C’s and their own coal cars. These unit trains were maintained by Detroit Edison but operated by Penn Central (Conrail after 4/1/76) crews. The arrangement lasted at least 20 years when the DE locomotive fleet began to wear out. By that time, Conrail was more than prepared to pick up the slack.

This operation was born from the 1970 bankruptcy of Penn Central. PC was unable to provide enough locomotives and hoppers that were in good repair to keep the coal moving between the mines in Pennsylvania’s Monongahela region and the DE power plant in Monroe, Michigan. So, Detroit Edison acquired a fleet of their own locomotives, including SD40’s and U30C’s and their own coal cars. These unit trains were maintained by Detroit Edison but operated by Penn Central (Conrail after 4/1/76) crews. The arrangement lasted at least 20 years when the DE locomotive fleet began to wear out. By that time, Conrail was more than prepared to pick up the slack.

Brand/Importer Information: DeLuxe Innovations is a "wholesale manufacturer" of model trains. We manufacture scale replica train models and sell them to hobby shops and distributors worldwide. 2013 marked the 20 year anniversary of DeLuxe Innovations brand trains. There are over 25 body styles in our product line and all of the cars in our single and multi-car packs have different road numbers. DeLuxe Innovations, Inc. is owned by Dave Ferrari, founder of Squeak N Products. We are located in Midland Park, New Jersey. When Dave purchased the business it was located in Burbank, California which would have been a bit of a long commute so the move to the East Coast was planned. Our first East Coast location was in Whippany, NJ along the Whippany River.

The business was started in 1993 by George Johnsen and Roberta Liebreich in Burbank, California. They had a philosophy that just wouldn't allow using a coal car as a "stand in" for a woodchip car, or printing any and all boxcar paint schemes on a PS-1. Starting with the release of the first ever etched metal parts for a ready to run car (1994's Twinstack's metal walkways) through the full dimension underframe and etched metal roofwalk (1996's 1944 AAR Boxcar) to the challenging RoadRailer system (2000), our products have been accurate to target the modeler or enthusiast.

You can also follow DeLuxe on Twitter

The business was started in 1993 by George Johnsen and Roberta Liebreich in Burbank, California. They had a philosophy that just wouldn't allow using a coal car as a "stand in" for a woodchip car, or printing any and all boxcar paint schemes on a PS-1. Starting with the release of the first ever etched metal parts for a ready to run car (1994's Twinstack's metal walkways) through the full dimension underframe and etched metal roofwalk (1996's 1944 AAR Boxcar) to the challenging RoadRailer system (2000), our products have been accurate to target the modeler or enthusiast.

You can also follow DeLuxe on Twitter

Item created by: Powderman on 2018-10-08 18:20:35. Last edited by CNW400 on 2020-05-29 10:52:06

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.