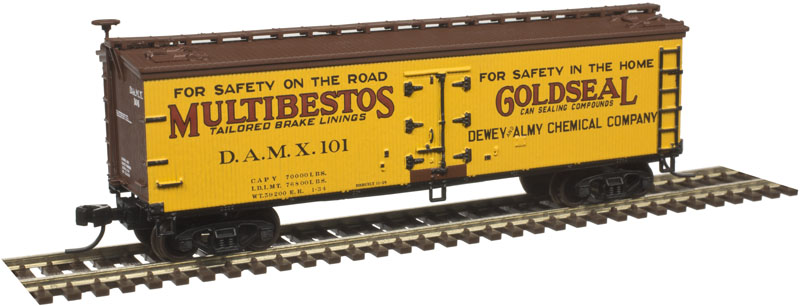

Model Information: This car was first introduced by Atlas in 1969. The first releases were made by Rivarossi for Atlas. Recent releases (like most Atlas products) are made in China.

Atlas has become so clever with modeling and painting that it can be difficult to tell what has been molded on and painted from separately-applied parts. The roofwalk and brake wheel are separate, and the ice hatches actually can be opened. Operators often sent shipments that didn't require refrigeration with the hatches open to provide ventilation, or you may wish to model an icing station with the hatches open and tiny people pushing tiny blocks of ice. Door hinges and most ladders and rungs are molded and cleverly painted.

The extreme width of these cars is 10 feet 1.44 inches. This is very close to the measurement range for cars of this type. The roofwalk length is 41 feet 7.68 inches, just about right for a 40 foot car, since the forty foot measures the interior space. Wooden reefers were not especially tall, so a measurement of 14 feet 5-1/8 inches is just about right. These cars represent that period of history where they rolled on Bettendorf 50 ton trucks but still had vertical brake wheels.

Much of what these cars represent can only be seen with a heavy magnifier. Using a 12X hand lens, the board siding is not just a collection of grooves; the individual planks have actual wood grain in them. All of the tiny lettering on the side is actually legible. Lettering and paint have been beautifully applied to a surface that can be almost hostile for paint and decals.

Atlas has become so clever with modeling and painting that it can be difficult to tell what has been molded on and painted from separately-applied parts. The roofwalk and brake wheel are separate, and the ice hatches actually can be opened. Operators often sent shipments that didn't require refrigeration with the hatches open to provide ventilation, or you may wish to model an icing station with the hatches open and tiny people pushing tiny blocks of ice. Door hinges and most ladders and rungs are molded and cleverly painted.

The extreme width of these cars is 10 feet 1.44 inches. This is very close to the measurement range for cars of this type. The roofwalk length is 41 feet 7.68 inches, just about right for a 40 foot car, since the forty foot measures the interior space. Wooden reefers were not especially tall, so a measurement of 14 feet 5-1/8 inches is just about right. These cars represent that period of history where they rolled on Bettendorf 50 ton trucks but still had vertical brake wheels.

Much of what these cars represent can only be seen with a heavy magnifier. Using a 12X hand lens, the board siding is not just a collection of grooves; the individual planks have actual wood grain in them. All of the tiny lettering on the side is actually legible. Lettering and paint have been beautifully applied to a surface that can be almost hostile for paint and decals.

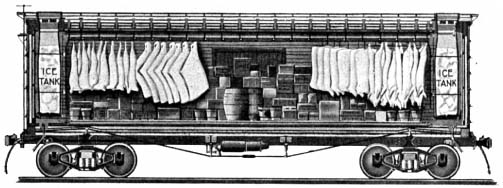

Prototype History: During the mid-19th century, attempts were made to ship agricultural products by rail. As early as 1842, the Western Railroad of Massachusetts was reported in the June 15 edition of the Boston Traveler to be experimenting with innovative freight car designs capable of carrying all types of perishable goods without spoilage. The first refrigerated boxcar entered service in June 1851, on the Northern Railroad (New York) (or NRNY, which later became part of the Rutland Railroad). This "icebox on wheels" was a limited success since it was only functional in cold weather. That same year, the Ogdensburg and Lake Champlain Railroad (O&LC) began shipping butter to Boston in purpose-built freight cars, utilizing ice for cooling.

The first consignment of dressed beef left the Chicago stock yards in 1857 in ordinary boxcars retrofitted with bins filled with ice. Placing meat directly against ice resulted in discoloration and affected the taste, proving to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars with their doors removed, and made a few test shipments to New York during the winter months over the Grand Trunk Railway (GTR). The method proved too limited to be practical.

The use of ice to refrigerate and preserve food dates back to prehistoric times. Through the ages, the seasonal harvesting of snow and ice was a regular practice of many cultures. China, Greece, and Rome stored ice and snow in caves, dugouts or ice houses lined with straw or other insulating materials. Rationing of the ice allowed the preservation of foods during hot periods, a practice that was successfully employed for centuries. For most of the 19th century, natural ice (harvested from ponds and lakes) was used to supply refrigerator cars. At high altitudes or northern latitudes, one foot tanks were often filled with water and allowed to freeze. Ice was typically cut into blocks during the winter and stored in insulated warehouses for later use, with sawdust and hay packed around the ice blocks to provide additional insulation. A late-19th century wood-bodied reefer required re-icing every 250 miles (400 km) to 400 miles (640 km).

From Wikipedia

The first consignment of dressed beef left the Chicago stock yards in 1857 in ordinary boxcars retrofitted with bins filled with ice. Placing meat directly against ice resulted in discoloration and affected the taste, proving to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars with their doors removed, and made a few test shipments to New York during the winter months over the Grand Trunk Railway (GTR). The method proved too limited to be practical.

The use of ice to refrigerate and preserve food dates back to prehistoric times. Through the ages, the seasonal harvesting of snow and ice was a regular practice of many cultures. China, Greece, and Rome stored ice and snow in caves, dugouts or ice houses lined with straw or other insulating materials. Rationing of the ice allowed the preservation of foods during hot periods, a practice that was successfully employed for centuries. For most of the 19th century, natural ice (harvested from ponds and lakes) was used to supply refrigerator cars. At high altitudes or northern latitudes, one foot tanks were often filled with water and allowed to freeze. Ice was typically cut into blocks during the winter and stored in insulated warehouses for later use, with sawdust and hay packed around the ice blocks to provide additional insulation. A late-19th century wood-bodied reefer required re-icing every 250 miles (400 km) to 400 miles (640 km).

From Wikipedia

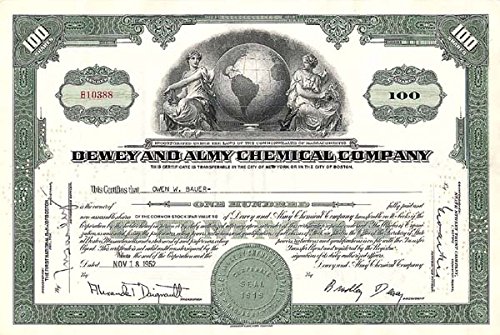

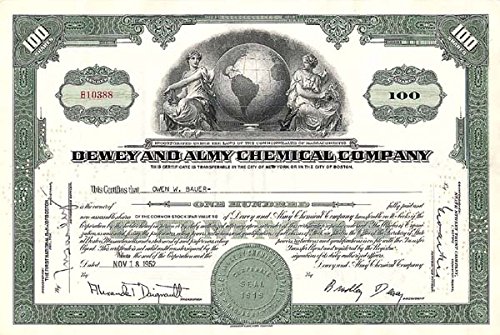

Road Name History:  One of the later comers into the Cambridge industrial field is the Dewey & Almy Chemical Co., occupying an acre and a half of land at the end of Harvey street, North Cambridge Junction. Operations were begun in November, 1919. The personnel of the firm includes Col. Bradley Dewey, late of the gas defence division of the United States army, who was awarded the distinguished service medal, and Lieut-Col. Charles Almy, sou of Judge Charles Almy. of this city. These gentlemen are chemical engineers and were classmates both at Harvard and Technology. They graduated from the latter with the class of '09. Col. Dewey is a son of Prof. Davis R. Dewey, of Technology, and before entering the U. S. service was director of research for one of the subsidiary companies of the U. 3. Steel corporation. Lieut.-Col. Almy was for seven years manager of the Virginia Red Oil Products Co.

One of the later comers into the Cambridge industrial field is the Dewey & Almy Chemical Co., occupying an acre and a half of land at the end of Harvey street, North Cambridge Junction. Operations were begun in November, 1919. The personnel of the firm includes Col. Bradley Dewey, late of the gas defence division of the United States army, who was awarded the distinguished service medal, and Lieut-Col. Charles Almy, sou of Judge Charles Almy. of this city. These gentlemen are chemical engineers and were classmates both at Harvard and Technology. They graduated from the latter with the class of '09. Col. Dewey is a son of Prof. Davis R. Dewey, of Technology, and before entering the U. S. service was director of research for one of the subsidiary companies of the U. 3. Steel corporation. Lieut.-Col. Almy was for seven years manager of the Virginia Red Oil Products Co.

The factory, 90x93 feet, is of steel and continuance sash construction with a monitor. The company is capitalised at $180,000, and at present employs 25 men. The principal products, which find a market throughout New England and in Chicago and Baltimore, include a special adhesive for sticking cork discs into bottle caps; rubber vulcanising cement for brushes; a shellac substitute for "doping" seams of food containers; and "Grippit," an entirely new adhesive designed for universal use. The two distinguishing features of "Grippit" are that it cannot wrinkle tissue paper and the smears around the edges are easily cleaned off with the lingers without soiling them. Plans are now forming for a large increase of the firm's products in the near future. At present it ia doing a volume of business at the rate of 8125,000 a year.

From the Cambridge Tribune, 1920

The factory, 90x93 feet, is of steel and continuance sash construction with a monitor. The company is capitalised at $180,000, and at present employs 25 men. The principal products, which find a market throughout New England and in Chicago and Baltimore, include a special adhesive for sticking cork discs into bottle caps; rubber vulcanising cement for brushes; a shellac substitute for "doping" seams of food containers; and "Grippit," an entirely new adhesive designed for universal use. The two distinguishing features of "Grippit" are that it cannot wrinkle tissue paper and the smears around the edges are easily cleaned off with the lingers without soiling them. Plans are now forming for a large increase of the firm's products in the near future. At present it ia doing a volume of business at the rate of 8125,000 a year.

From the Cambridge Tribune, 1920

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: gdm on 2018-08-14 09:43:32

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.