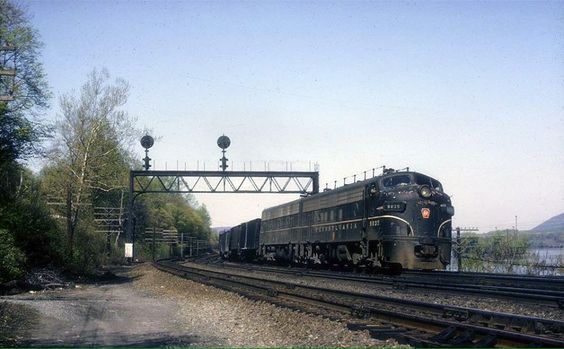

History: The EMD FP7 was a 1,500 horsepower (1,100 kW), B-B dual-service passenger and freight-hauling diesel locomotive produced between June 1949 and December 1953 by General Motors' Electro-Motive Division and General Motors Diesel. Final assembly was at GM-EMD's La Grange, Illinois plant, excepting locomotives destined for Canada, in which case final assembly was at GMD's plant in London, Ontario. The FP7 was essentially EMD's F7A locomotive extended by four feet to give greater water capacity for the steam generator for heating passenger trains.

While EMD's E-units were successful passenger engines, their A1A-A1A wheel arrangement made them less useful in mountainous terrain. Several railroads had tried EMD's F3 in passenger service, but there was insufficient water capacity in an A-unit fitted with dynamic brakes. The Atchison, Topeka and Santa Fe Railway's solution was to replace the steam generators in A-units with a water tank, and so only fitted steam generators into the B-units. The Northern Pacific Railway's solution was to fit extra water tanks into the first baggage car, and to pipe the water to the engines. The real breakthrough came when EMD recognized the problem and added the stretched FP7 to its catalog.

A total of 381 cab-equipped lead A units were built; unlike the freight series, no cables booster B units were sold. Regular F7B units were sometimes used with FP7 A units, since they, lacking cabs, had more room for water and steam generators. The FP7 and its successor, the FP9, were offshoots of GM-EMD's highly successful F-unit series of cab unit freight diesels.

F3s, F7s, and F9s equipped for passenger service are not FP-series locomotives, which although similar in appearance have distinctive differences, including but not limited to the greater body length. The extra 4 ft (1.2 m) of length was added behind the first body-side porthole, and can be recognised by the greater distance between that porthole and the first small carbody filter grille. The corresponding space beneath the body, behind the front truck, was also opened up; this either remained an empty space or was filled with a distinctive water tank shaped like a barrel mounted transversely.

Railroads found that Fs, with their better tractive effort performed much better than Es in passenger service on routes with stiff grades. However, as a freight model lacking steam generators it was not a possible unless a separate heating car was used or Es were in the consist. EMD corrected the issue with its FP7, released in the late 1940s, built at the same time as the F7. Surprisingly, for a variant model the locomotive sold quite well with nearly 400 examples manufactured (including those constructed by General Motors Diesel of London, Ontario). Today, numerous FP7s remain preserved and in operation around the country.

From Wikipedia

Read more on American-Rails.com

While EMD's E-units were successful passenger engines, their A1A-A1A wheel arrangement made them less useful in mountainous terrain. Several railroads had tried EMD's F3 in passenger service, but there was insufficient water capacity in an A-unit fitted with dynamic brakes. The Atchison, Topeka and Santa Fe Railway's solution was to replace the steam generators in A-units with a water tank, and so only fitted steam generators into the B-units. The Northern Pacific Railway's solution was to fit extra water tanks into the first baggage car, and to pipe the water to the engines. The real breakthrough came when EMD recognized the problem and added the stretched FP7 to its catalog.

A total of 381 cab-equipped lead A units were built; unlike the freight series, no cables booster B units were sold. Regular F7B units were sometimes used with FP7 A units, since they, lacking cabs, had more room for water and steam generators. The FP7 and its successor, the FP9, were offshoots of GM-EMD's highly successful F-unit series of cab unit freight diesels.

F3s, F7s, and F9s equipped for passenger service are not FP-series locomotives, which although similar in appearance have distinctive differences, including but not limited to the greater body length. The extra 4 ft (1.2 m) of length was added behind the first body-side porthole, and can be recognised by the greater distance between that porthole and the first small carbody filter grille. The corresponding space beneath the body, behind the front truck, was also opened up; this either remained an empty space or was filled with a distinctive water tank shaped like a barrel mounted transversely.

Railroads found that Fs, with their better tractive effort performed much better than Es in passenger service on routes with stiff grades. However, as a freight model lacking steam generators it was not a possible unless a separate heating car was used or Es were in the consist. EMD corrected the issue with its FP7, released in the late 1940s, built at the same time as the F7. Surprisingly, for a variant model the locomotive sold quite well with nearly 400 examples manufactured (including those constructed by General Motors Diesel of London, Ontario). Today, numerous FP7s remain preserved and in operation around the country.

From Wikipedia

Read more on American-Rails.com

Railroad/Company: Electro-Motive Diesel (EMD) is an American manufacturer of diesel-electric locomotives, locomotive products and diesel engines for the rail industry. The company is owned by Caterpillar through its subsidiary Progress Rail Services Corporation.

Electro-Motive Diesel traces its roots to the Electro-Motive Engineering Corporation, a designer and marketer of gasoline-electric self-propelled rail cars founded in 1922 and later renamed Electro-Motive Company (EMC). In 1930, General Motors purchased Electro-Motive Company and the Winton Engine Co., combining the two to form its Electro-Motive Division (EMD) in 1941.

In 2005, GM sold EMD to Greenbriar Equity Group and Berkshire Partners, which formed Electro-Motive Diesel to facilitate the purchase. In 2010, Progress Rail Services completed the purchase of Electro-Motive Diesel from Greenbriar, Berkshire, and others.

EMD's headquarters, engineering facilities and parts manufacturing operations are based in McCook, Illinois, while its final locomotive assembly line is located in Muncie, Indiana. EMD also operates a traction motor maintenance, rebuild and overhaul facility in San Luis Potosí, Mexico.

As of 2008, EMD employed approximately 3,260 people, and in 2010 it held approximately 30 percent of the market for diesel-electric locomotives in North America.

From Wikipedia

Electro-Motive Diesel traces its roots to the Electro-Motive Engineering Corporation, a designer and marketer of gasoline-electric self-propelled rail cars founded in 1922 and later renamed Electro-Motive Company (EMC). In 1930, General Motors purchased Electro-Motive Company and the Winton Engine Co., combining the two to form its Electro-Motive Division (EMD) in 1941.

In 2005, GM sold EMD to Greenbriar Equity Group and Berkshire Partners, which formed Electro-Motive Diesel to facilitate the purchase. In 2010, Progress Rail Services completed the purchase of Electro-Motive Diesel from Greenbriar, Berkshire, and others.

EMD's headquarters, engineering facilities and parts manufacturing operations are based in McCook, Illinois, while its final locomotive assembly line is located in Muncie, Indiana. EMD also operates a traction motor maintenance, rebuild and overhaul facility in San Luis Potosí, Mexico.

As of 2008, EMD employed approximately 3,260 people, and in 2010 it held approximately 30 percent of the market for diesel-electric locomotives in North America.

From Wikipedia

Item Links: We found: 1 different collections associated with Rail - Locomotive - EMD FP7

- Collection N Scale Model Trains: 73 different items.

Item created by: gdm on 2018-02-13 10:02:30. Last edited by Alain LM on 2021-01-17 06:25:42

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.