Model Information: Atlas first announced this model in 2013 with a target release data of 2nd quarter, 2014. It is part of the Atlas Master product group. Atlas uses this body style to model both 2750 and 2960 c.f. 3-bay open hoppers as made by the Pullman Standard company. Pullman produced over 16,000 prototype cars. The model features:

- Fifteen Panels;

- Sixteen Side Posts;

- Die-cast hopper and center sill construction;

- Late 20th century prototype (New cars were built from 1954-1971);

- Optional heap shields;

- Friction- or roller-bearing trucks.

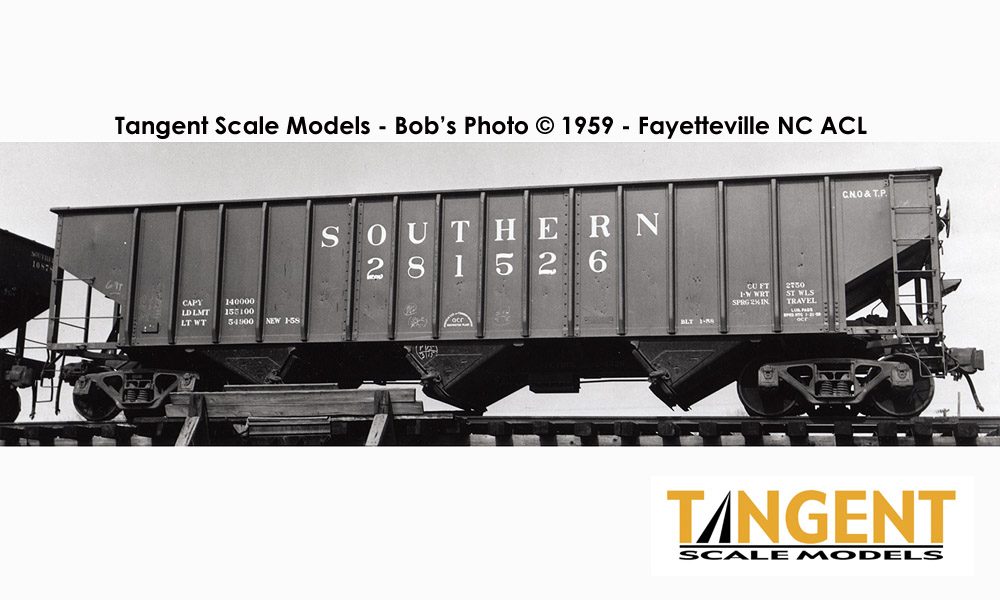

Prototype History: During the 1950s, Pullman-Standard began to develop a “standardized” line of freight car product types that were marketed in “families”. Starting with the PS-1 boxcars and PS-2 covered hoppers, the PS-3 was rolled out with several offerings, the most prolific being this 70-ton, 3-outlet coal hopper with a cubic capacity of 2750 cubic feet. First purchased in 1957, Pullman-Standard not only had an effective marketing message with the “PS” series, but developed simultaneous production capability at both its Bessemer AL and Butler PA manufacturing plants, providing customers with a rapid response for coal hoppers that were produced at a rate of more than 13 cars per weekday during peak supply. Such rapid-production was made possible by new welding techniques that arose from the World War II period, although this was a relatively new innovation for open hoppers at the time.

Buyers for the PS-3 hoppers varied widely across US freight car buyers – in other words Class I railroads. The largest purchaser of the PS-3 was Louisville and Nashville, who settled on Pullman-Standard produced 2 and 3 bay hoppers as their fleet standard for coal originations prior to the 1970s. While they placed several orders for PS-3 hoppers, for a total of more than 8,000 cars(!), here is an example of one of the cars from the L&N 1959 order wearing fresh factory paint, where the cars from that period carried the “Dixie Line” paint that lasted into the 1980s.

Buyers for the PS-3 hoppers varied widely across US freight car buyers – in other words Class I railroads. The largest purchaser of the PS-3 was Louisville and Nashville, who settled on Pullman-Standard produced 2 and 3 bay hoppers as their fleet standard for coal originations prior to the 1970s. While they placed several orders for PS-3 hoppers, for a total of more than 8,000 cars(!), here is an example of one of the cars from the L&N 1959 order wearing fresh factory paint, where the cars from that period carried the “Dixie Line” paint that lasted into the 1980s.

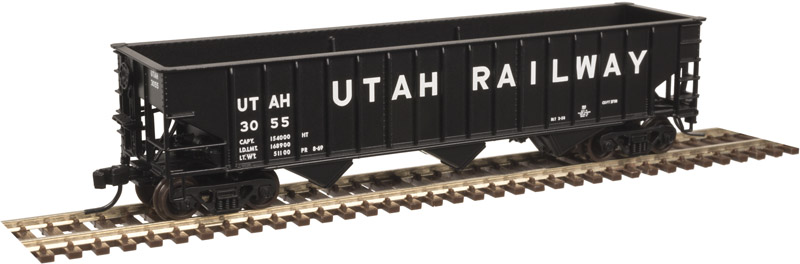

Road Name History: The Utah Railway was completed in 1914 to connect several coal mines south and west of Helper, Utah (on the Rio Grande mainline) with the outside world. The Utah branches connect with the Rio Grande at Utah Railway Junction, just northwest of Helper. The Utah then utilizes trackage rights on the Rio Grande northwest to Thistle. The remainder of the line between Thistle and Provo is on paired track with Rio Grande (later SP then UP.) Total mileage is 95.

In the steam era, the locomotive fleet consisted of a quartet of 2-8-0’s (likely for switching the mines), nine 2-10-2’s for road service, and a trio of 2-8-8-0’s which were probably used as helpers. All seem to have been of Union Pacific design.

The Utah Railway dieselized in 1952 with seven Alco RSD4’s and a bit later an RSD5. As traffic began to build in the modern era, they picked up three RSD15’s and an RSD12. In 1985, they began relying on leased power from Helm and later from MK.

The 1996 merger of Southern Pacific and Union Pacific changed things for the Utah. First, they were contracted by BNSF to handle their haulage trains over a portion of the “Central Corridor” as UP calls the old Rio Grande. Secondly, UP granted Utah trackage rights east from Utah Railway Junction all the way to Grande Junction, Colorado which linked the Utah Railway to several more large coal mines. At this point, Utah hired a number of new people and leased more than a dozen additional diesels for heavy road service. Now stretching from Grande Junction to Provo, Salt Lake City and Ogden, the Utah Railway operates 423 miles of track. In addition to coal, UTAH moves aggregate, brick, building materials, cement, chemicals and petroleum products.

In 1999, Utah purchased the Salt Lake City Southern, a 25 mile shortline in the area from its owner RailTex. Owned by a string of mining companies over the years, the Utah was sold in 2002 to the Genesee & Wyoming shortline group for $54 million. Today's collection of photos takes us from 1975 to 1988.

In the steam era, the locomotive fleet consisted of a quartet of 2-8-0’s (likely for switching the mines), nine 2-10-2’s for road service, and a trio of 2-8-8-0’s which were probably used as helpers. All seem to have been of Union Pacific design.

The Utah Railway dieselized in 1952 with seven Alco RSD4’s and a bit later an RSD5. As traffic began to build in the modern era, they picked up three RSD15’s and an RSD12. In 1985, they began relying on leased power from Helm and later from MK.

The 1996 merger of Southern Pacific and Union Pacific changed things for the Utah. First, they were contracted by BNSF to handle their haulage trains over a portion of the “Central Corridor” as UP calls the old Rio Grande. Secondly, UP granted Utah trackage rights east from Utah Railway Junction all the way to Grande Junction, Colorado which linked the Utah Railway to several more large coal mines. At this point, Utah hired a number of new people and leased more than a dozen additional diesels for heavy road service. Now stretching from Grande Junction to Provo, Salt Lake City and Ogden, the Utah Railway operates 423 miles of track. In addition to coal, UTAH moves aggregate, brick, building materials, cement, chemicals and petroleum products.

In 1999, Utah purchased the Salt Lake City Southern, a 25 mile shortline in the area from its owner RailTex. Owned by a string of mining companies over the years, the Utah was sold in 2002 to the Genesee & Wyoming shortline group for $54 million. Today's collection of photos takes us from 1975 to 1988.

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: gdm on 2017-07-31 14:39:11. Last edited by gdm on 2021-02-20 21:42:10

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.