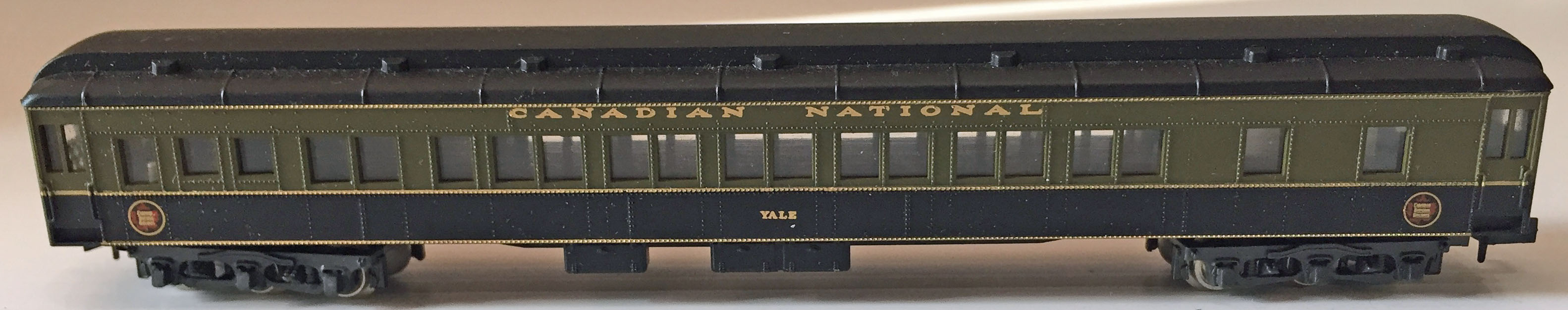

Prototype History: Heavyweight Passenger Cars were the prevalent style of railcars used for passenger service during the interwar period. They were constructed of concrete, wood and steel. The floor was often of poured concrete, which helped give these cars a smoother ride than older wooden-body cars. Also, because of their heavy construction, they were also much less likely to "telescope" when a collision occurred. They were much heavier than modern passenger cars due to the materials used in their construction. They were so heavy that they often (but not always) required three-axle bogies to support them.

Heavyweights frequently had what is called a clerestory roof. The center of the roof was higher than the sides, in that it was stepped up. The lightweight cars had smooth, rounded roofs. Heavyweight passenger cars typically weigh around 1 ton per foot of length. So a 85' car weighs in the area of 85 tons for a heavyweight car.

From Wikipedia

Heavyweights frequently had what is called a clerestory roof. The center of the roof was higher than the sides, in that it was stepped up. The lightweight cars had smooth, rounded roofs. Heavyweight passenger cars typically weigh around 1 ton per foot of length. So a 85' car weighs in the area of 85 tons for a heavyweight car.

From Wikipedia

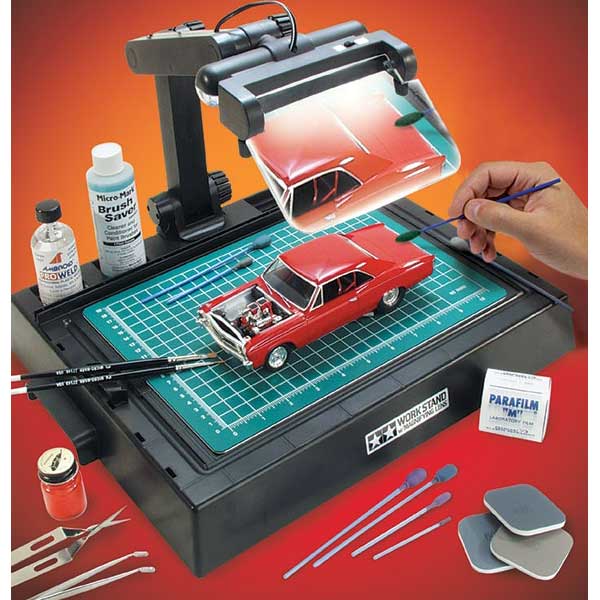

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: gdm on 2017-07-19 20:48:52. Last edited by CNW400 on 2021-10-06 21:07:46

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.