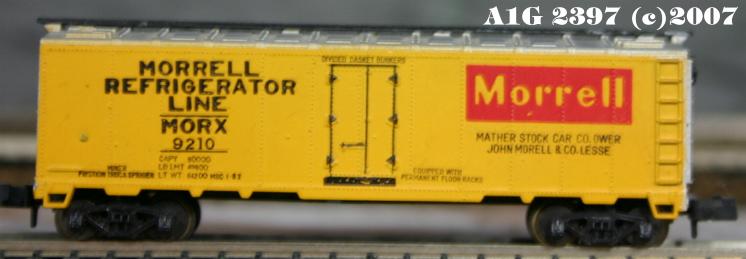

Model Information: Rivarossi first started producing this model for Atlas in 1969. It appears in the Atlas catalog with 8 Road Names at $1.50 each. After Atlas discontinued importing this model, Arnold/Rivarossi used these cars as parts of various freight sets released under the Arnold/Rivarossi label.

Prototype History: A refrigerator car (or “reefer”) is a refrigerated boxcar (US) or van (UIC), a piece of railroad rolling stock designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple insulated boxcars and ventilated boxcars (commonly used for transporting fruit), neither of which are fitted with cooling apparatus. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or utilize carbon dioxide (either as dry ice, or in liquid form) as a cooling agent. Milk cars (and other types of “express” reefers) may or may not include a cooling system, but are equipped with high-speed trucks and other modifications that allow them to travel with passenger trains.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

By the 1940's, new reefers were being built entirely of steel. Insulating techniques improved to the point where economical refrigeration could be accomplished using steel side plates in place of wood sheathing. Cars with steel roofs and sides were more durable and required fewer repairs.

The General American Transportation Corporation built several 40' steel reefer for the Union Refrigerator Transit Line (URTX) from the late 1940's into the 1950's.

This reefer was 40' long & weighted 61,500 lbs. The car is a steel bodied reefer with iced bunkers at each end. These ice bunkers hold 10,400 lbs. of chunk ice or 11,500 lbs. of crushed ice. Ice stations were located every 100-150 miles along the railroads main line to replace the melted ice. In the winter, charcoal heaters could be placed in the bunkers to keep the cargo from freezing. Fans are located in the floor at each end to circulate air and keep an even temperature throughout the car. Typical cargo would be fresh fruit, vegetables or eggs.

American Car & Foundry (ACF Industries) also built 40' reefer for several companies.

Road Name History: The John Morrell brand's tradition of excellence began back in 1827 in Bradford, England, and continues today across the United States. Shoppers know that the John Morrell name stands for premium-quality meat products, including ham, hardwood-smoked bacon, smoked sausage, and much more.

Brand/Importer Information: In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: gdm on 2017-03-24 10:56:17. Last edited by gdm on 2020-05-26 07:33:22

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.