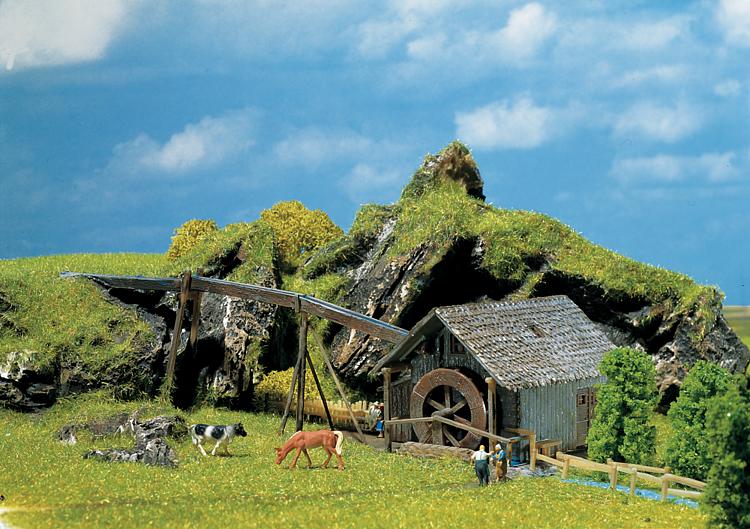

Specific Item Information: Over 70 Two Story Combination Type 22 depots were built by the Southern Pacific Railroad between 1899 and 1910. They were more commonly found in California, but examples were also located in Texas, Arizona, Utah, Oregon, and Nevada. A prominent feature of the Type 22 depot is the two-story high rectangular shaped bay window. The structure, which exhibited horizontal wood siding, typically measured 25 feet wide. The second story, with the same width of 25 feet, was usually 32 feet in length or longer. The freight room was built long enough to accommodate the SP’s anticipated business at that location and ranged in size from 30 to 84 feet in length. Other variations between Type 22 depots also existed such as loading dock size, window and door arrangements, and roof design as well as mirrored floor plans. In fact, our latest N scale SP depot offering is considered a “left hand” version of this famous depot design due to the location of its bay window. Examples of “left handed” Type 22s could be found in California at La Verne, Palmdale, Grass Lake, and Chatsworth while numerous “right hand” versions existed as well. Our structure kit displays a 25 foot wide by 38 foot 6 inch long two-story portion with a 42 foot long freight room. As usual, the kit is 100% laser-cut and utilizes Peel & Stick and Tab & Slot construction. Features include: 3-Tab shingles, loading dock with wood deck, positionable window sashes, authentic gable trim, and accurately shaped brackets. Optional detail parts include bay ticket window and three different chimney styles so the modeler can best match the model to the prototype they are representing on their layout. The assembled structure measures 6.75” long x 2.75” wide x 2.5” high. The loading dock adds 2.75” to length and 0.75 “ to width.

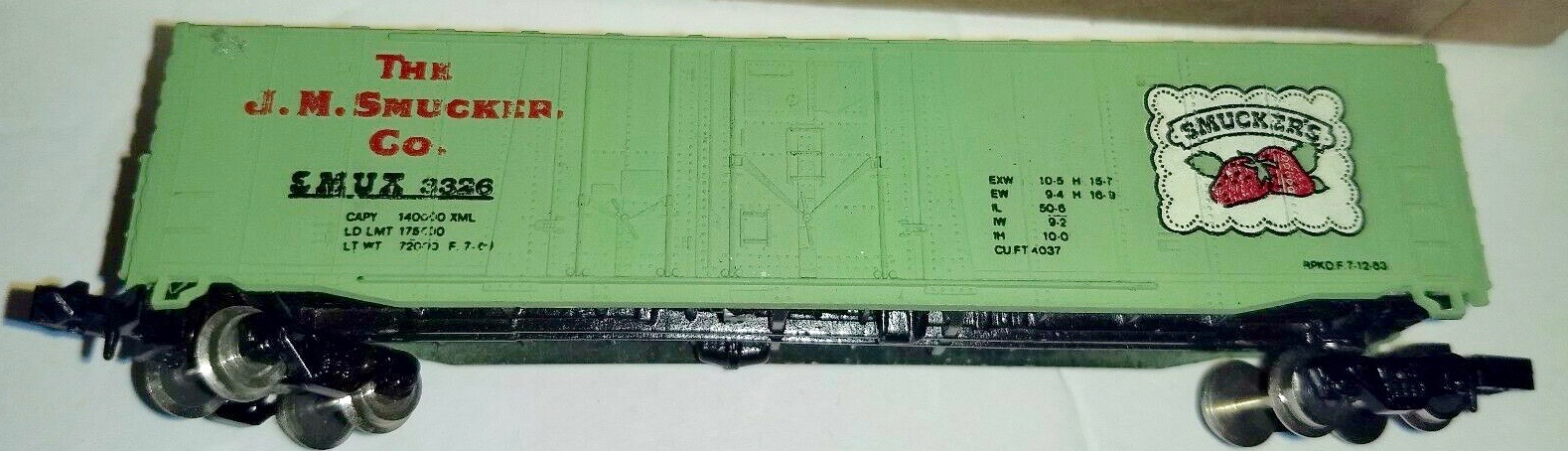

Road Name History:  Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

Although they may be molded in color, unpainted and unlettered, undecorated products are marketed to modelers who seek to custom decorate their models for private roads and/or road and/or company names that were not commercially produced by any of the major manufacturers.

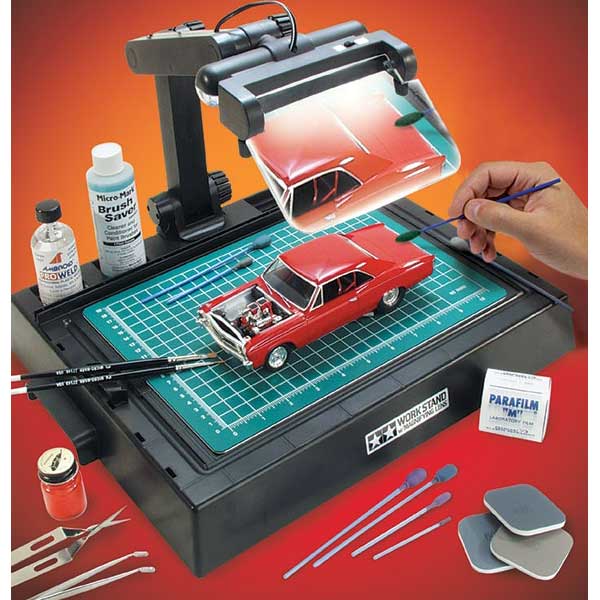

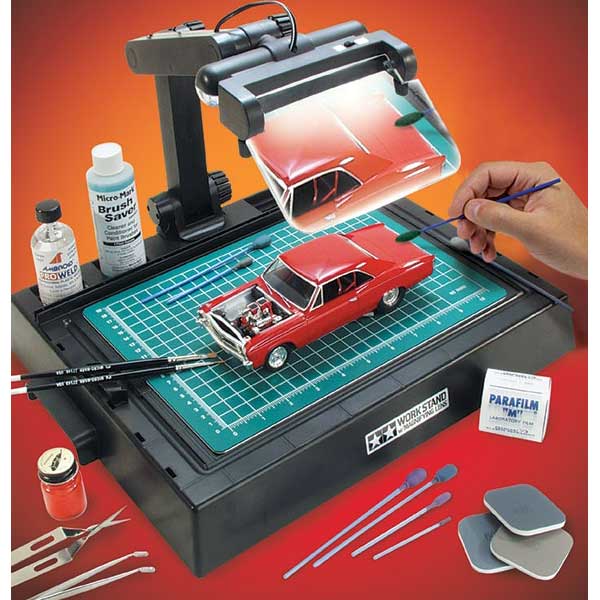

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Undecorated models are frequently also unassembled or only partially assembled and required modelers to be comfortable with glue, paint and sometimes solder in order to prepare their models for display. Materials for these models can vary but often include plastic, pewter and resin. Models may or may not come with decals or other decorations such as plastic signage, railings and ladders to enhance the appearance of the final product.

Brand/Importer Information: LASERKITS are designed in a Computer Assisted Drafting (CAD) program, then laser-machined at our computer-controlled laser workstations.

LASERKITS are cut and engraved from high quality woods (and occasionally styrene) with incredible precision and accuracy. The resulting edges are clean, need little, if any, sanding, and yield precise details, and exact-fitting parts.

There is no frustrating, time-consuming, board by board construction with LASERKITS. Side and roof pieces are tabbed and slotted, so no error can be made during assembly. Windows, doors, roofing materials, shingles, and trim boards are all laser-cut, and have a self adhesive backing which has been tested in the St. Louis summer heat and humidity, and found to hold under the most adverse conditions.

American Model Builders, Inc. 8229 Brentwood Industrial Drive St. Louis, MO 63144 Phone: 314-646-8588 Fax: 314-646-8583 Email: laserkit@sbcglobal.net

LASERKITS are cut and engraved from high quality woods (and occasionally styrene) with incredible precision and accuracy. The resulting edges are clean, need little, if any, sanding, and yield precise details, and exact-fitting parts.

There is no frustrating, time-consuming, board by board construction with LASERKITS. Side and roof pieces are tabbed and slotted, so no error can be made during assembly. Windows, doors, roofing materials, shingles, and trim boards are all laser-cut, and have a self adhesive backing which has been tested in the St. Louis summer heat and humidity, and found to hold under the most adverse conditions.

American Model Builders, Inc. 8229 Brentwood Industrial Drive St. Louis, MO 63144 Phone: 314-646-8588 Fax: 314-646-8583 Email: laserkit@sbcglobal.net

Item created by: nscalestation on 2017-01-06 23:44:18

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.