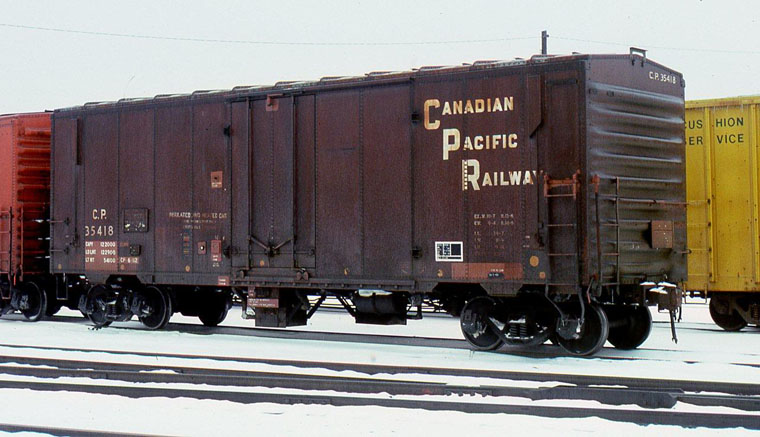

Model Information: This model was originally produced by Kato for Con-Cor. Since Con-Cor owned the tooling, they were later able to move the tooling to Chicago for later runs. It has been marketed as a "40' Steel Box Car[sic]" as well as "40' Steel Reefer". We believe current runs are being made in China. Pictures of this model were available as of May 2017 on the Con-Cor website being sold with two options for couplers: Rigid-Face and Micro-Trains.

Prototype History: Plug-Door boxcars are usually insulated and typically carry products such as canned goods that require protection from extremes of temperature but do not require refrigeration. Plug-style doors were normally used to ensure a tight seal in the insulation. Designed for transport of both perishables and large loads, plug doors allowed box cars to be sealed from outside dust and dirt. Cars like these were manufactured during the 50s and 60s.

Whether you consider this a reefer or a boxcar is a matter for angel-pinhead-counters. There seems to be a bit of a blurry line during the transition era between the idea of a steel ice reefer and an insulated boxcar. I guess an ice reefer was meant to hold ice for cooling but I doubt this is a cut-and-dry distinction. Modern "mechanical" reefers are a different breed as they contain a refrigeration unit which quite distinctly sets them apart from "boxcars".

Whether you consider this a reefer or a boxcar is a matter for angel-pinhead-counters. There seems to be a bit of a blurry line during the transition era between the idea of a steel ice reefer and an insulated boxcar. I guess an ice reefer was meant to hold ice for cooling but I doubt this is a cut-and-dry distinction. Modern "mechanical" reefers are a different breed as they contain a refrigeration unit which quite distinctly sets them apart from "boxcars".

Road Name History:  The Armour Refrigerator Line (ARL, one of the Armour Car Lines) was a private refrigerator car line established in 1883 by Chicago meat packer Philip Armour, the founder of Armour and Company.

The Armour Refrigerator Line (ARL, one of the Armour Car Lines) was a private refrigerator car line established in 1883 by Chicago meat packer Philip Armour, the founder of Armour and Company.

To get his products to market, Armour followed the lead of rivals George Hammond and Gustavus Swift when he established the Armour Refrigerator Line in 1883. Armour's endeavor soon became the largest private refrigerator car fleet in America. By 1900, the company listed over 12,000 units on its roster (one-third of all the privately owned cars in the country), all built in Armour's own car plant.

One of the Armour Car Lines' subsidiaries was dedicated to produce hauling. In 1919 the Federal Trade Commission ordered the company's sale for anti-trust reasons. On March 18 of the following year the new entity, to be known as Fruit Growers Express (FGE), would take with it 4,280 pieces of rolling stock, repairs shops at Alexandria, Virginia and Jacksonville, Florida, and numerous ice plants and other facilities scattered throughout the East Coast.

The General American Transportation Corporation assumed ownership of the line in 1932.

From Wikipedia

To get his products to market, Armour followed the lead of rivals George Hammond and Gustavus Swift when he established the Armour Refrigerator Line in 1883. Armour's endeavor soon became the largest private refrigerator car fleet in America. By 1900, the company listed over 12,000 units on its roster (one-third of all the privately owned cars in the country), all built in Armour's own car plant.

One of the Armour Car Lines' subsidiaries was dedicated to produce hauling. In 1919 the Federal Trade Commission ordered the company's sale for anti-trust reasons. On March 18 of the following year the new entity, to be known as Fruit Growers Express (FGE), would take with it 4,280 pieces of rolling stock, repairs shops at Alexandria, Virginia and Jacksonville, Florida, and numerous ice plants and other facilities scattered throughout the East Coast.

The General American Transportation Corporation assumed ownership of the line in 1932.

From Wikipedia

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: gdm on 2016-12-09 13:33:53. Last edited by gdm on 2018-03-22 15:19:34

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.