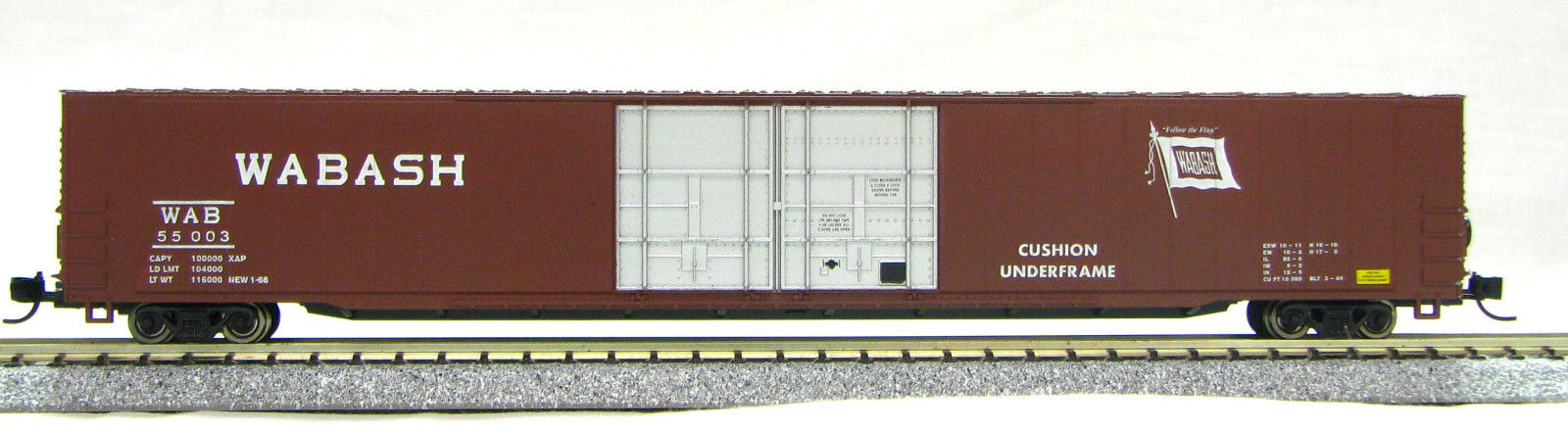

Prototype History: The three major automobile manufacturers in the United States, Chrysler, Ford, and General Motors, each developed specifications in the 1960s for specially built boxcars to transport automobile parts (not actual cars). They stated, if you build this type of car, your will be welcome to pick up and drop off parts at our plants. Thousands of these cars were built in the 1960s and 1970s. Three railcar manufacturers, Greenville, Pullman-Standard and Thrall took up the challenge and constructed 86 foot boxcars.

These cars are not only distinctive for their length (86 foot, also listed as 85 foot) but also for the fact that they were designed for a post-roofwalk world so they took advantage of the fact they didn't need to leave room for the roofwalk and instead are simply built taller. Hence they are considered High-Cube cars. They come in two major varieties: 8-door and 4-door. The eight door types were typically made for use at GM plants and have two sets of 9 foot doors on each side. When these doors are full opened, they created a pair of 18 foot opening on each side of the car. Their 4-door sisters, as specified by Ford and Chrysler, had one pair of 10 foot doors centered on each side, permitting a 20 foot opening.

As containers gradually replaced these cars for use in the auto industry, many were re-purposed for use in other industries that involve low-density commodities such as scrap paper.

These cars are not only distinctive for their length (86 foot, also listed as 85 foot) but also for the fact that they were designed for a post-roofwalk world so they took advantage of the fact they didn't need to leave room for the roofwalk and instead are simply built taller. Hence they are considered High-Cube cars. They come in two major varieties: 8-door and 4-door. The eight door types were typically made for use at GM plants and have two sets of 9 foot doors on each side. When these doors are full opened, they created a pair of 18 foot opening on each side of the car. Their 4-door sisters, as specified by Ford and Chrysler, had one pair of 10 foot doors centered on each side, permitting a 20 foot opening.

As containers gradually replaced these cars for use in the auto industry, many were re-purposed for use in other industries that involve low-density commodities such as scrap paper.

Road Name History: Wabash was the product of an 1889 restructuring (under the leadership of Jay Gould) of several railroads centered around the Wabash St. Louis & Pacific. Wabash was unusual in that it evenly straddled the border between “eastern railroads” and railroads west of the Chicago-St.Louis-Memphis-New Orleans border. In the west, Wabash connected Kansas City, Omaha and Des Moines. Heading east from those points, Wabash reached St. Louis, Decatur, and Chicago. Then, clearly in the eastern territory, Wabash reached Fort Wayne, Detroit, Toledo and finally Buffalo. Total length was about 2500 miles. The Detroit to Buffalo line cut though southern Ontario, Canada on Canadian National trackage rights. That route also required a car float operation across the Detroit River. As a result, Wabash’s Buffalo traffic was a fraction of that of competitors Nickel Plate and New York Central. However, Wabash’s Detroit-Kansas City and Detroit-St. Louis service was a force to be reckoned with and well patronized by Michigan’s automakers. The Wabash Cannonball was the name of the daytime passenger run between Detroit and St. Louis. The song of the same name was a hit long before it was ever applied to the train itself. Wabash bought control of the Ann Arbor in 1925 and soon after, Wabash and Delaware & Hudson jointly bought control of the Lehigh Valley (Wabash’s principle connection in Buffalo.) This got the attention of the Pennsylvania Railroad who bought control of Wabash under the auspices of their “Pennsylvania Company” subsidiary in 1928.

As PRR planned their merger with New York Central, it became obvious that they could not take Wabash with them. The first step was to transfer control of Ann Arbor from Wabash to Detroit Toledo & Ironton (also in the Pennsylvania Company family.) Up to that point, Ann Arbor was routinely included in the official Wabash system map. Then PRR arranged for Wabash to be included in the Norfolk & Western-Nickel Plate-Pittsburgh & West Virginia merger that was being planned. PRR didn’t overtly control the N&W but they did have considerable influence over them. The deal was made and the new, larger Norfolk & Western leased the Wabash for 50 years in October of 1964. At that point, Wabash became a paper railroad. They were finally merged out of existence by N&W successor Norfolk Southern in the 1990s.

As PRR planned their merger with New York Central, it became obvious that they could not take Wabash with them. The first step was to transfer control of Ann Arbor from Wabash to Detroit Toledo & Ironton (also in the Pennsylvania Company family.) Up to that point, Ann Arbor was routinely included in the official Wabash system map. Then PRR arranged for Wabash to be included in the Norfolk & Western-Nickel Plate-Pittsburgh & West Virginia merger that was being planned. PRR didn’t overtly control the N&W but they did have considerable influence over them. The deal was made and the new, larger Norfolk & Western leased the Wabash for 50 years in October of 1964. At that point, Wabash became a paper railroad. They were finally merged out of existence by N&W successor Norfolk Southern in the 1990s.

Brand/Importer Information: Con-Cor has been in business since 1962. Many things have changed over time as originally they were a complete manufacturing operation in the USA and at one time had upwards of 45 employees. They not only designed the models,but they also built their own molds, did injection molding, painting, printing and packaging on their models.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Currently, most of their manufacturing has been moved overseas and now they import 90% of their products as totally finished goods, or in finished components. They only do some incidental manufacturing today within the USA.

Important Note: The Con-Cor product numbering can be very confusing. Please see here in the article how to properly enter Con-Cor stock numbers in the TroveStar database.

Item created by: gdm on 2016-10-28 11:00:20. Last edited by CNW400 on 2020-05-15 15:48:00

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.