Prototype History: During the mid-19th century, attempts were made to ship agricultural products by rail. As early as 1842, the Western Railroad of Massachusetts was reported in the June 15 edition of the Boston Traveler to be experimenting with innovative freight car designs capable of carrying all types of perishable goods without spoilage. The first refrigerated boxcar entered service in June 1851, on the Northern Railroad (New York) (or NRNY, which later became part of the Rutland Railroad). This "icebox on wheels" was a limited success since it was only functional in cold weather. That same year, the Ogdensburg and Lake Champlain Railroad (O&LC) began shipping butter to Boston in purpose-built freight cars, utilizing ice for cooling.

The first consignment of dressed beef left the Chicago stock yards in 1857 in ordinary boxcars retrofitted with bins filled with ice. Placing meat directly against ice resulted in discoloration and affected the taste, proving to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars with their doors removed, and made a few test shipments to New York during the winter months over the Grand Trunk Railway (GTR). The method proved too limited to be practical.

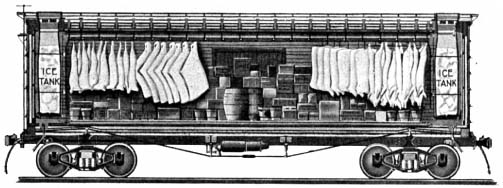

The use of ice to refrigerate and preserve food dates back to prehistoric times. Through the ages, the seasonal harvesting of snow and ice was a regular practice of many cultures. China, Greece, and Rome stored ice and snow in caves, dugouts or ice houses lined with straw or other insulating materials. Rationing of the ice allowed the preservation of foods during hot periods, a practice that was successfully employed for centuries. For most of the 19th century, natural ice (harvested from ponds and lakes) was used to supply refrigerator cars. At high altitudes or northern latitudes, one foot tanks were often filled with water and allowed to freeze. Ice was typically cut into blocks during the winter and stored in insulated warehouses for later use, with sawdust and hay packed around the ice blocks to provide additional insulation. A late-19th century wood-bodied reefer required re-icing every 250 miles (400 km) to 400 miles (640 km).

From Wikipedia

The first consignment of dressed beef left the Chicago stock yards in 1857 in ordinary boxcars retrofitted with bins filled with ice. Placing meat directly against ice resulted in discoloration and affected the taste, proving to be impractical. During the same period Swift experimented by moving cut meat using a string of ten boxcars with their doors removed, and made a few test shipments to New York during the winter months over the Grand Trunk Railway (GTR). The method proved too limited to be practical.

The use of ice to refrigerate and preserve food dates back to prehistoric times. Through the ages, the seasonal harvesting of snow and ice was a regular practice of many cultures. China, Greece, and Rome stored ice and snow in caves, dugouts or ice houses lined with straw or other insulating materials. Rationing of the ice allowed the preservation of foods during hot periods, a practice that was successfully employed for centuries. For most of the 19th century, natural ice (harvested from ponds and lakes) was used to supply refrigerator cars. At high altitudes or northern latitudes, one foot tanks were often filled with water and allowed to freeze. Ice was typically cut into blocks during the winter and stored in insulated warehouses for later use, with sawdust and hay packed around the ice blocks to provide additional insulation. A late-19th century wood-bodied reefer required re-icing every 250 miles (400 km) to 400 miles (640 km).

From Wikipedia

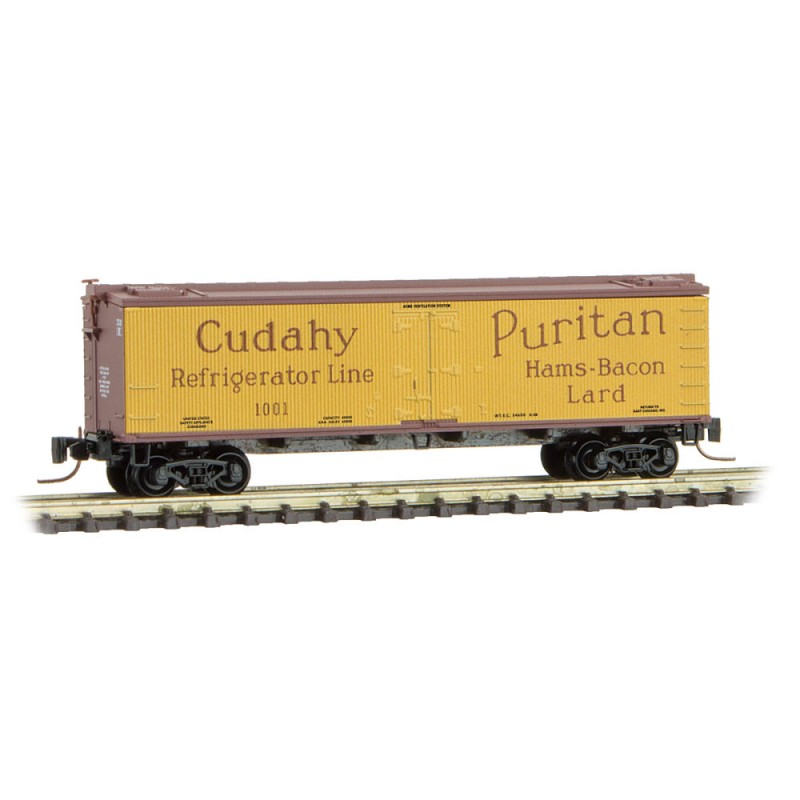

Road Name History: Cudahy Packing Company was a U.S. meat packing company established in 1887 as the Armour-Cudahy Packing Company and incorporated in Maine in 1915. It was founded by Patrick Cudahy (March 17, 1849 - July 25, 1919) and his brother John Cudahy, Irish immigrants from County Kilkenny whose family came to Milwaukee, Wisconsin, to avoid the Great Irish Famine. The original business is no longer in existence, but legacies are evident in Cudahy, Wisconsin (established by Patrick Cudahy as a base for his meatpacking business that still exists as the Patrick Cudahy division of Smithfield Foods).

The Cudahy meat packing plant in Chicago, sacked the silica/punice from their Meade County mine for soaking up blood on the kill floor. They also had a subsidiary plant that manufactured cleaning products that utilized the silica. Old Dutch Cleanser was first registered as a trademark for this silica-based cleaning product. Old Dutch cleansing powder was first created by Cudahy Packing, a Chicago-based company specialized in the slaughtering of animals. In 1905, while looking for a way to recuperate animal fat for use in the production of soap, Cudahy Packing became the first company to market cleansing powder. Highly innovative for that time, this unique product completely revolutionized household cleaning, greatly facilitating the task.

By the mid-1920s, Cudahy was one of the nation's leading food companies, with over $200 million in annual sales and 13,000 employees around the country. The business was hit by the Great Depression, but the company still employed about 1,000 Chicago-area residents during the mid-1930s. Following World War II it moved its headquarters first to Omaha and then in 1956 to Phoenix, where it took the name Cudahy Co. In 1957, the company was one of 500 companies listed in the first S&P 500. The company was dismantled in the 1970s, after it was purchased by General Host in 1968. The Cudahy packing business was sold to management in 1981; it was renamed Bar-S Foods. Bar-S was acquired by the Mexican packer Sigma Alimentos in 2010.

From Wikipedia and other sources

The Cudahy meat packing plant in Chicago, sacked the silica/punice from their Meade County mine for soaking up blood on the kill floor. They also had a subsidiary plant that manufactured cleaning products that utilized the silica. Old Dutch Cleanser was first registered as a trademark for this silica-based cleaning product. Old Dutch cleansing powder was first created by Cudahy Packing, a Chicago-based company specialized in the slaughtering of animals. In 1905, while looking for a way to recuperate animal fat for use in the production of soap, Cudahy Packing became the first company to market cleansing powder. Highly innovative for that time, this unique product completely revolutionized household cleaning, greatly facilitating the task.

By the mid-1920s, Cudahy was one of the nation's leading food companies, with over $200 million in annual sales and 13,000 employees around the country. The business was hit by the Great Depression, but the company still employed about 1,000 Chicago-area residents during the mid-1930s. Following World War II it moved its headquarters first to Omaha and then in 1956 to Phoenix, where it took the name Cudahy Co. In 1957, the company was one of 500 companies listed in the first S&P 500. The company was dismantled in the 1970s, after it was purchased by General Host in 1968. The Cudahy packing business was sold to management in 1981; it was renamed Bar-S Foods. Bar-S was acquired by the Mexican packer Sigma Alimentos in 2010.

From Wikipedia and other sources

Brand/Importer Information: Micro-Trains Line split off from Kadee Quality Products in 1990. Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Item created by: CNW400 on 2022-03-09 17:10:20. Last edited by CNW400 on 2022-03-09 17:16:53

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.