Bachmann Trains Tropicana ACF Steel Reefer

Published: 2024-07-01 - By: CNW400

Last updated on: 2024-07-02

Last updated on: 2024-07-02

visibility: Public - Headline

Juice Train History

Shortly after the end of World War I, Anthony Rossi left his homeland of Italy and migrated to New York City – hoping to make it big in the entertainment industry. He instead made a living working in various careers – machinist, taxi/limousine driver, and farmer before owning a grocery store for 13 years. In the early 1940’s, Anthony desired a warmer climate and traveled to Virginia and Florida and decided to officially settle in Palmetto, Florida. There he founded the Manatee River Packing Company and used his New York connections to provide gift fruit boxes and canned jars of the exotic Florida jewels of grapefruits and oranges to such clientele as Macy’s, Gimbel’s, and the Waldorf Astoria Hotel.Anthony expanded his business and relocated to Bradenton, Florida and rebranded his company as Fruit Industries. There his company began to supply frozen concentrated orange juice. In 1954 his company developed and perfected one of the most important discoveries in the food and beverage industry – flash pasteurization. Flash pasteurization (also known as HTST / high-temperature short time) is a process where cold beverages are exposed to very high temperatures (160°F – 165°F) for a brief period (15-30 seconds) and then cooled-down quickly (39°F – 42°F). This process destroys harmful bacteria, molds, and yeast – extending shelf life more than 12 months. This method has been adopted during the production of juice, beer, wine, milk, and cheese. Also, this same year, according to the official company website, Tropicana Pure Premium orange juice in spoiled-resistant glass containers was introduced for the first time. Legend says Mr. Rossi “borrowed” and trademarked the name after spotting a tourist area called Tropicana Cabins along Route US-41 in Florida.

The large cities up North thirsted for the taste of fresh orange juice from Florida. Intially to meet the great demand, an 8000-ton cargo ship christened the SS Tropicana was placed into service in 1957. The ship hauled 1.5 million gallons of juice weekly in a stainless-steel tank from Cocoa, Florida (later Port Canaveral) to a Tropicana owned distribution plant in Whitestone, New York. The SS Tropicana made her final voyage in 1961 with Mr. Rossi shifting his attention exclusively to trucking and railroad transportation.

Tropicana began to use insulated boxcars to deliver their juice products to their Kearney, New Jersey plant. In 1970, Tropicana desired a more reliable, faster, and frequent freight service from Florida to New Jersey. The first single customer express unit train for the food and beverage industry was formed. Tropicana began to ship orange juice via insulated boxcars weekly. This expanded into two 60-railcar unit trains hauling over 1 million gallons of juice twice a week over the 1200-mile route.

In 1971, the Great White Juice Train was born – 150 100-ton insulated boxcars painted white with Tropicana lettering made its inaugural run to the North. The train grew with another 100 cars with specialty equipped mechanical refrigeration built to keep the juice product at a cool 34°F added into the mix. Each railcar carried four truck loads worth off juice product.

Traveling at a maximum speed of 60 mph – the Juice Train began on Seaboard Coast Line track (old Seaboard Air Line & Atlantic Coast Line routes) just south of Tampa, Florida onto Richmond, Fredericksburg, and Potomac rails near Richmond, Virginia over to the Penn Central electrified overhead wire lines near Alexandria, Virginia into New Jersey. The Tropicana unit Juice Train began to travel five days a week up the East Coast. Each was regularly scheduled and took about 48 hours to complete the entire route. The trip back south to Florida carried back empties or backhauled items from the North the need insulation (produce, ketchup, beverages, etc.) for sale in the southern states.

The Tropicana mechanical refrigerated units and RBL insulated boxcars (Refrigerator Bunklerless Load restraints) were company owned and run with the TPIX road marker. Tropicana had their own railcar department and New Jersey-based GE 70-ton plant switcher – engine number #98. Tropicana originally painted all of their rolling stock white before adding orange-colored cars into the mix in 1977. New white rolling stock returned in 1983 with a mixture of both white and orange cars since. The unique and easy to spot juice cars became a great advertising tool and a favorite of railfans. Leased USLX green and blue double-plug door cars were incorporated on shorter runs and smaller shipments not latched to the giant Juice Train.

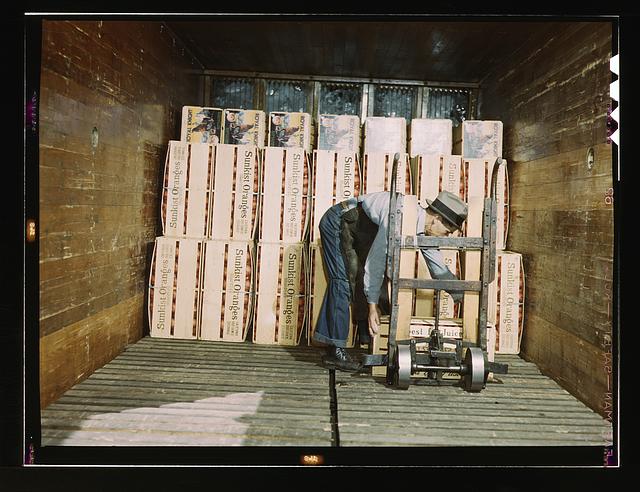

Some changes along the over 50-year history of the Tropicana Juice Train includes Conrail taking control of Penn Central in 1976 and discontinued electrified service in 1981. By 1999 CSX Transportation Company acquired controlling interests of Seaboard System Railroad (1981), Richmond, Fredericksburg, and Potomac (1991), and Conrail (1999). CSX controlled the entire route and began to haul product from Florida to a new larger, more modern Tropicana distribution plant built in Greenville-Jersey City, New Jersey starting in 1991. Tropicana facilities process 1.7 million gallons of juice daily! Millions of oranges are squeezed each day – pasteurized – boxed & crated – loaded with a forklift…taking one hour to fully load a car.

CSX Transportation abolished the Juice Train in 2017. Tropicana juice cars are now hauled with other types of rolling stock under CSX power from Florida to Philadelphia, Pennsylvania. Short-line traffic runs the Tropicana product 90-miles north from Philadelphia to the Greenville-Jersey City plant. Furthermore, weekly trips run from Florida to distribution centers in Cincinnati, Ohio and over 3000 miles to City of Industry, California (just east of Los Angeles).

Bachmann Prototype History

ACF (American Car and Foundry Company) is a manufacturer of railroad rolling stock that was founded 1899. It is currently known as ACF Industries LLC with its headquarters located in St. Charles, Missouri. ACF was one of the first railcar companies to embrace the wooden, ice-cooled refrigerator car design during the turn of the twentieth century and prospered building cars for the meat (Swift Refrigerator Line) and beer (Anheuser-Busch) industries. The early ice-bunker refrigerator cars were usually 40-foot long and required tons of ice to keep its lading cool during its journey.

The first all-steel reefer car was built in 1936 with riveted side panels and fans to circulate the cool air throughout the interior of the railcar. In 1949, mechanical refrigeration cars were developed with cooling equipment designed for the frozen food industry. These 40–50-foot cars had air cooling equipment with a small diesel engine mounted at one end that controlled a compressor, fan, and thermostat to maintain a steady, constant internal temperature. A sliding screen door allowed access to this equipment. Mounted underbody tanks held the diesel fuel needed to run the cooling system. Since these mechanical reefers were more expensive to manufacture and service, their use was usually reserved for frozen foods and the conventional, insulated ice-bunker cars for such items that didn’t require freezing temperatures (produce, beverages, canned goods etc.). Many first-generation steel reefers were later retrofitted with mechanical cooling units The early 1960’s saw the developments of the 57-foot mechanical reefer and private ownership of these railcars.

The Bachmann Tropicana car represents a RBL type reefer: “a bunkerless refrigerator car with or without ventilating devices and with or without a device for attaching portable heaters. Constructed with insulation in sides, ends, floor, and roof…equipped in addition with adjustable loading or stowing device” – Official Railway Equipment Register. Advances with insulation material, such as polystyrene foam, enhanced internal temperature control of boxcars without the need for ice or refrigeration. The insulated boxcar was not designed to cool its lading, but instead maintain a consistent internal temperature within a few degrees over a several days. Internal load restraints (straps, cargo bars, etc.) braced and/or locked the lading into placed to avoid shifting and potential damage to the product.

To achieve the objective to regulate the environment inside an insulated boxcar, the car was equipped with a plug door instead of the conventional sliding door. Plug doors fit snug inside an opening – providing a watertight seal to sustain internal temperature and greater safeguard from the weather, dirt, theft, and infestation. The plug door system, which closes with an inward movement that seals the door flush, is used on both insulated boxcars and refrigerator (reefer) cars.

The disadvantages of the plug door are higher a manufacturing investment during production, the added weight of the door, and greater maintenance costs associated with the plug door over the sliding door. The plug door is fabricated with a complex arrangement of locking bars, swinging arms, and braces – more parts to become damaged or worn-out and increasing material and labor costs for the railroads.

The Model

The ready-to-run steel reefer arrived in an oversized clear plastic jewel case with a slip-off cover. A two-piece plastic cradle protected the model, and a small plastic bag was found containing a pair of Rapido couplers for those wishing to replace the equipped E-Z Mate ® couplers. All information is neatly labeled on the end of the case for easy identification when placed into storage.

The blue Bachmann 50-foot steel reefer was released in December of 2022 with a suggested retail price of $37. Bachmann Trains has a lengthy history with the ACF 50-foot reefer – dating back to 1969. The current offerings of this model are included in their Silver Series collection that offers greater attention to detail and frequently includes separately attached parts and metal wheels. The most current releases of the Bachmann ACF 50-foot steel reefer car are:

- American Refrigerator Transit

- Canadian National

- Fruit Growers Express

- New York Central

- Tropicana Orange Juice (three colors available: blue, orange, and white)

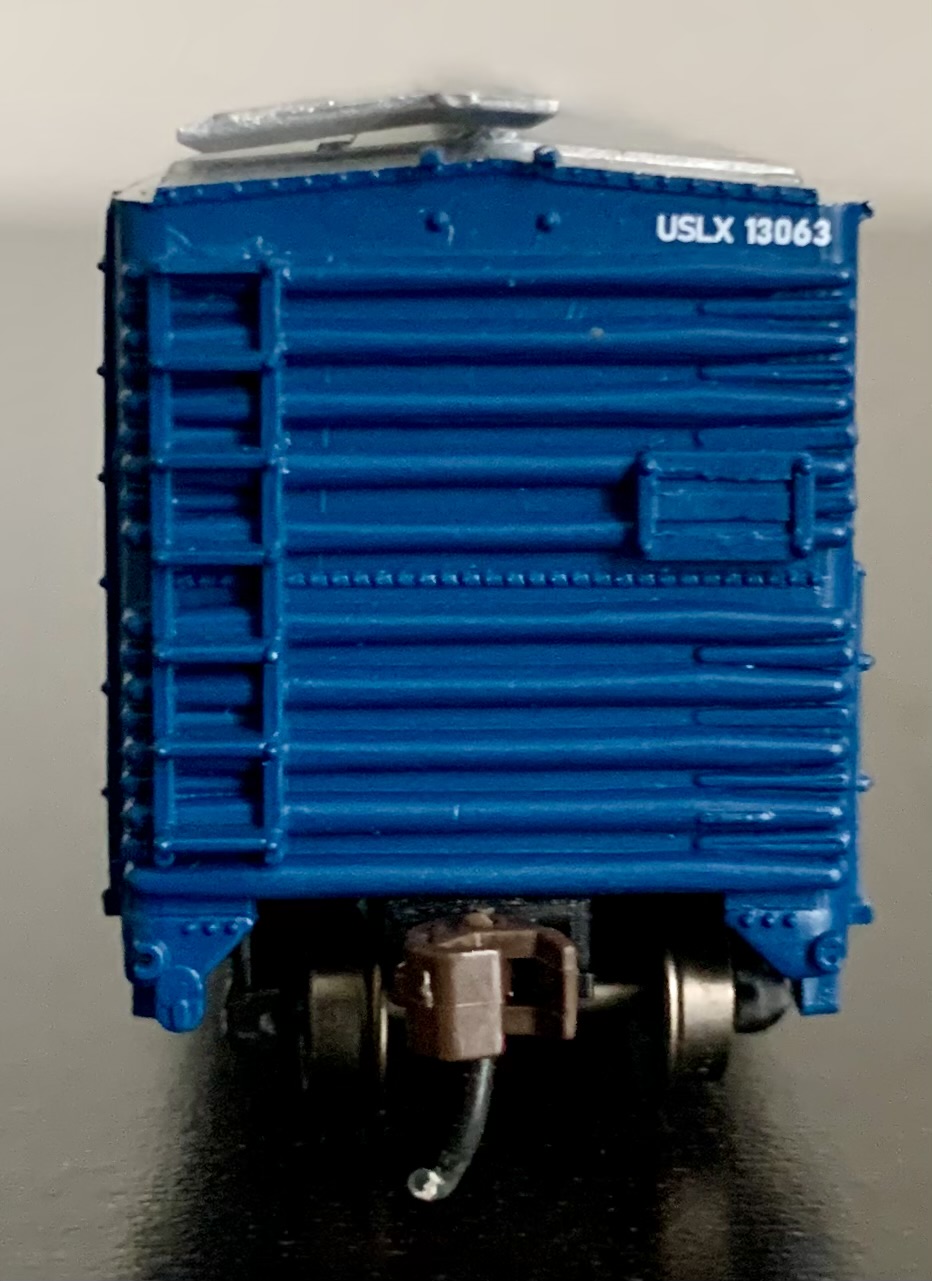

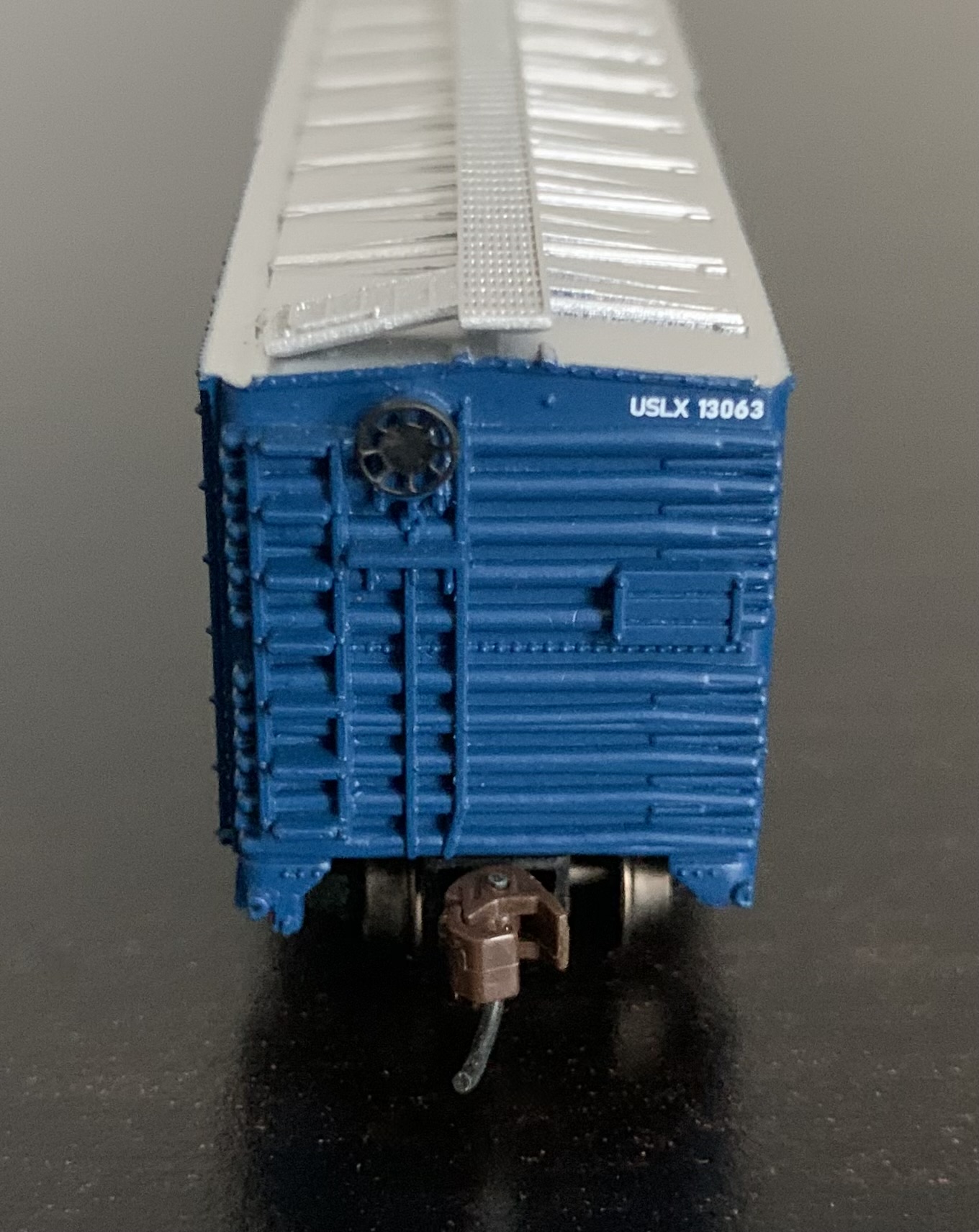

The paint scheme for this Bachmann Tropicana Orange Juice ACF 50-Foot Steel Reefer appears to be a fantasy design. I was not able to locate an image of a ‘real-life’ leased USLX (United States Leasing Co.) railcar and only one representation of a piece of model train rolling stock that shows a blue color Tropicana reefer car with a single plug door pattern (Roundhouse Models). Nearly all found examples display an Evans double plug-door configuration.

Another apparent error is the Association of American Railroads (AAR) freight car classification ‘ABL’ clearly stamped on the third panel of the model. I assume that should be ‘RBL’ (insulated bunkerless refrigerator car with loading devices) as found on every depiction of this refrigerator car. The spacing of lettering is also a mess – especially the Plate C height clearance stamped across rivets lines instead of being centered on a side panel.

The blue Bachmann steel reefer does display plenty of finely detailed sharp rivet lines, ventilation screens, and prototypical single plug-door design with two vertical door braces with diagonal locking bars (V-shaped design). On the other hand, the stirrup steps are a little too “chunky” for my liking.

The ends feature 5/5 Dreadnaught patterns with rounded corners for W-section corner posts. Also comprised of tapered ends with small corrugations between them. Includes prototypical mid-height mounted placard and full-length ladder on each end. The B-end sports a high-mounted brake wheel with molded brake rod and chain details. Road marker and road number are neatly stenciled in the upper right corners. The car ends are lacking in appeal – not clean and crisp for a premium series of model rolling stock.

The diagonal pattern welded roof panels extend the full width of the car except for the end panels – left flat for the latitudinal extensions and corner grab irons. An overhanging Tri-Lok metal running board is also installed. My model appears to have both ends of the running boards warped upwards.

The black underframe features a separately attached AB brake system with AB valve, brake cylinder, brake reservoir, and brake rod. The reefer car has pin mounted roller-bearing trucks with blackened metal wheels. Lastly, the model is equipped with proper height body mounted brown plastic E-Z Mate® Mark II couplers.

The steel reefer measured 3 5/8 inches and weighed 1.1 ounces, which just about perfect according to the National Model Railroad Association (NMRA) recommended weight of 1.07 ounces for a model this size. A fine runner with no problems while testing the reefer car on Kato Unitrack around curves or through turnouts at slow and medium speeds.

Conclusions

I am rather disappointed in this Bachmann rolling stock model that is marketed as a premium product. Apparently not very prototypical for a Tropicana Juice Train refrigerated car, typographical error, sloppy stamping, distorted running boards, and oversized details. It was an excellent runner that needed no adjustments – metal wheels and body-mounted couplers are a plus. A nice conversation piece with the Juice Train subject matter. But Bachmann has some cleaning-up to do the next time they try to squeeze my pocketbook.To View the Entire Collection of Bachmann 50 foot reefers: CLICK HERE

Photo Credits:

Barron, C. P. (1951) View Showing Oranges Being Harvested in the Groves. United States of America Florida Winter Garden, 1951. [Photograph] Retrieved from the Library of Congress.Delano, Jack, photographer. San Bernardino, California. Icing Atchison, Topeka and Santa Fe Railroad refrigerator cars at the ice plant. United States San Bernardino California San Bernardino County, 1943. Mar. Photograph. No known restrictions. Delano, Jack, photographer. Loading oranges into a refrigerator car at a co-op orange packing plant, Redlands, Calif. Santa Fe R.R. trip. United States Redlands California, 1943. March. No known restrictions