Broadway Limited Imports H32 Covered Hopper

Published: 2024-04-01 - By: CNW400

Last updated on: 2024-02-26

Last updated on: 2024-02-26

visibility: Public - Headline

Introduction

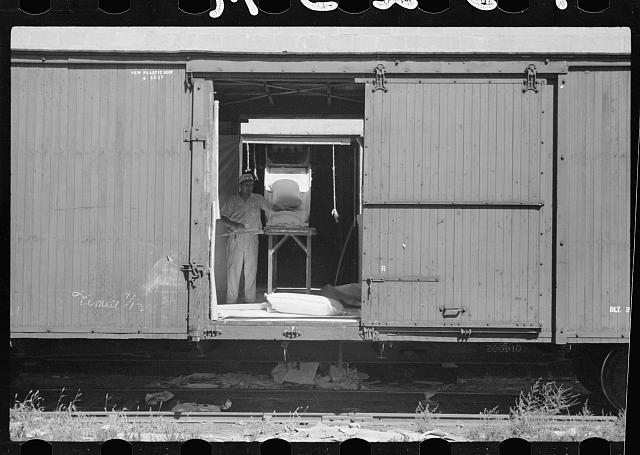

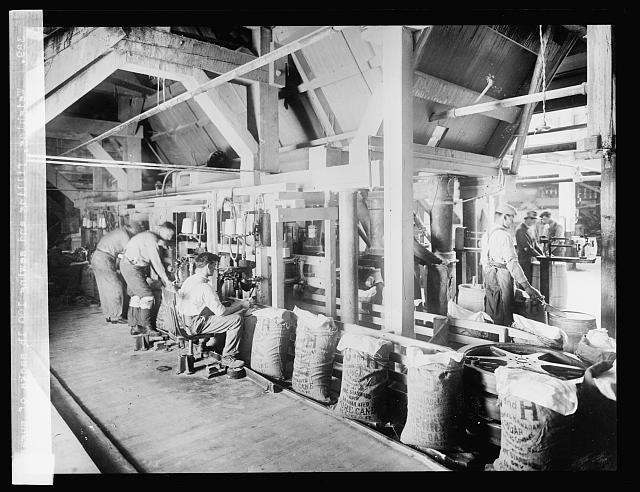

Open hopper and gondola railcars were a staple for the railroad industry from the beginning – hauling material that required little protection from the elements such as rock and coal. Railroads often resorted to the inefficient means of using wooden boxcars to haul product that demanded safeguard from wind, rain, and other forms of contamination. Bulk dry goods such as sugar and flour were sewn into 100-pound cloth sacks and loaded by hand…once one thousand sacks were packed, the weight limit for a 50-ton boxcar would be reached. The wood boxcars were often lined with paper to block rodent, bug, and moisture infestation and to protect the cloth sacks from tears. By the 1920s sugar and flour were filled into smaller paper sacks for retail customers – but this did not elevate the time-consuming job of loading and unloading the boxcars manually or the troubles with spoilage.

The railroad industry began to experiment with converting open hoppers by adding a waterproof cover with outlet gates on the bottom. Then by the mid-1930’s, covered hoppers were introduced by railcar builders to transport cement, lime, sand, and phosphate. These were mostly two-bay, 50 or 70-ton cars that simplified the hauling process by allowing the commodity to be filled through roof hatches and discharged out bottom gates.

Fine granulated products such as flour, sugar, and starch had difficulty flowing and fully emptying from a standard hopper. General American Transportation Corporation (today known as GATX) was the first to address this issue with the introduction of the Trans-Flo covered hopper in 1948. Looking for a more sanitary and efficient means to ship dry, powered goods – the 55-foot, 70-ton railcar used a pneumatic system (using gas or air under pressure) to unload a full car of its contents in just four hours (quick for that era). The Fuller Company Airveyor System was used on the Trans-Flo hooper – attaching flexible hoses to the underside of each bay discharge gate and introducing air to direct the flow of the dry product into storage tanks. Furthermore, the 3-bay hopper was constructed with rounded corners for each internal compartment to prevent product retention during unloading. Car vibrators were also utilized to assure a uniform flow and dislodge any “caked-up” or stuck lading. This car was popular with the flour, plastic, chemical, sugar, pharmaceutical, and dry milk industries.

Also built during the summer of 1948 at the Pennsylvania Railroad’s Altoona shops were a fleet of three hundred H32 covered hoppers. The H32 was a larger version of the PRR’s successful H30 model – both variations featured a low-profile truss-frame body with diagonal support posts angled from each end platform deck. The Pennsylvania Railroad built over 1,300 of the 34-foot long, 3-bay H30 covered hoppers from 1935 to 1952 to transport cement, sand, soda ash, and lime. The 70-ton H32 was 53-feet long with 5-bays and had a 3050 cubic foot capacity and was specifically designed to haul lighter, less-dense products.

The Prototype

The H32 covered hoppers featured an all-steel welded body with 14 roof loading hatches and metal Apex Tri-Lok metal running board. The railcars were assigned to the number series 253500 – 253799 and were delivered in four PRR paint schemes:- Freight Car Red with white letters and Circle Keystone

- Grey with black letters and Circle Keystone

- Grey with black letters and Shadow Keystone

- Grey with black letters and Plain Keystone

Other attempts to ship dry bulk good in an economic fashion that was speedy, yet also eliminated contamination included:

- Domino Sugar (American Sugar Refining Company) covered hopper ASRX #501. A one-of-a-kind prototype car built by the Pennsylvania Railroad in 1951. An old X-29 boxcar was converted into a 40-foot, 3-bay sugar hopper with a 2060 cubic foot capacity. This unique railcar stayed on the American Sugar fleet until the mid-1980s.

- The General American Transportation Corporation introduced the 2600-cubic foot Airslide covered hopper in 1954. This single-bay, 70-ton capacity railcar became the most fashionable way to haul fine dry bulk materials with over 5,000 built from 1954 to 1969.

- The General American Transportation Corporation Dry-Flo covered hopper was released in 1959 with a larger capacity of 3500 cubic-feet. The 3-bay hopper was popular with the soybean, oats, rice, corn, malt, and plastic industries. The Burlington Route (later Burlington Northern) was the biggest user of these hoppers with a roster of two hundred cars.

- American Car and Foundry (ACF) introduced pressure-differential hopper cars in 1964. The design was similar to a conventional hopper but had piping running along the outlet gates. The interior was pressurized and forced the material out the attached piping into a storage tank or directly transloaded into a truck for transport. Used for sugar, flour, and other fine lading.

Road Names and Pricing

Broadway Limited Imports released their most recent Pennsylvania Railroad H32 Covered Hopper collection in April 2022. Originally introduced in 2016 as a four-pack, Broadway Limited Imports newest series was made available this time in a twin-pack. Eleven different road names, in fourteen paint schemes, were produced…including eight fantasy reporting marks. Fantasy schemes represent decorative styles not officially issued by a rail company on true-life equipment:- Pennsylvania - Freight Car Red with Circle Keystone (2 Sets Available)

- Pennsylvania – Gray with Shadow Keystone (2 Sets Available)

- Pennsylvania – Gray with PRR and Keystone

- Pennsylvania – Pennsylvania with Circle Keystone

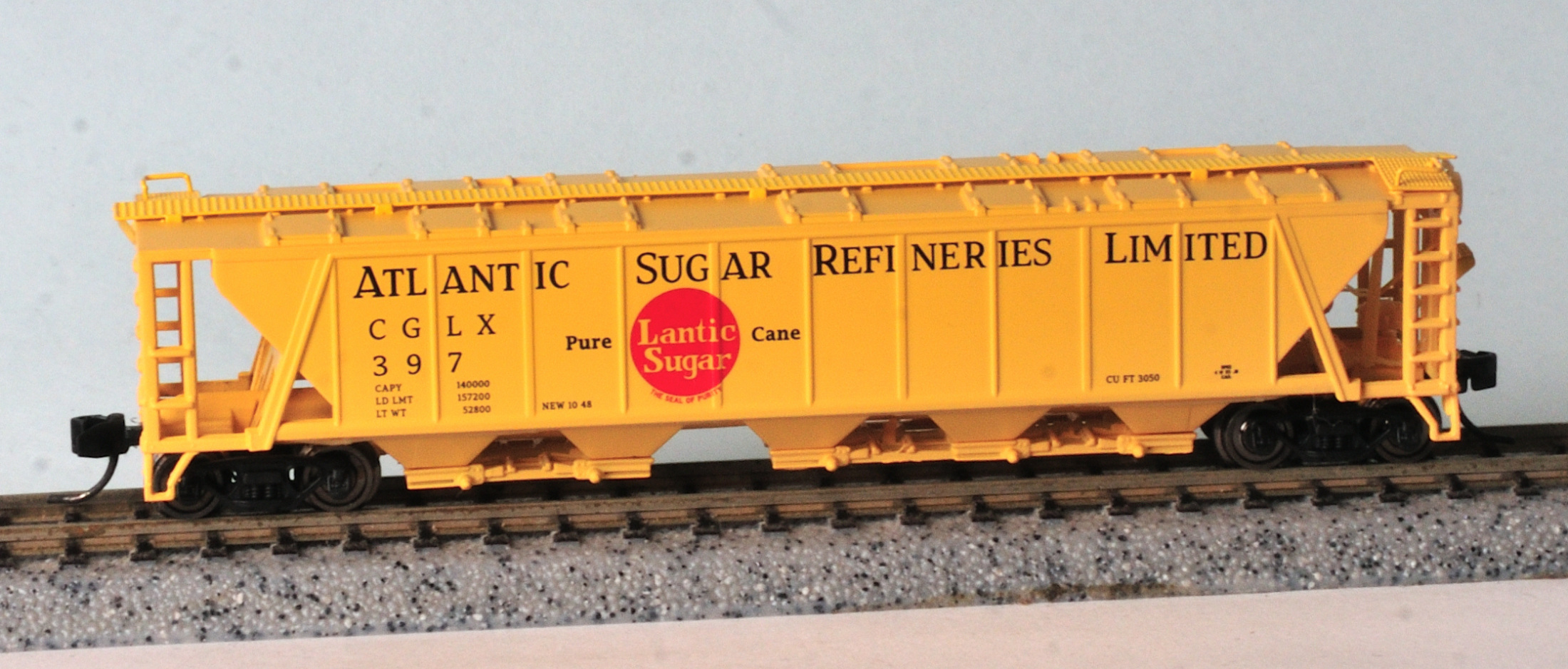

- Atlantic Sugar Refineries– Fantasy Scheme

- Canadian Pacific – Fantasy Scheme

- Chesapeake & Ohio – Fantasy Scheme

- Conrail

- FMC Chemicals – Fantasy Scheme

- Great Northern – Fantasy Scheme

- Milwaukee Road – Fantasy Scheme

- Penn Central

- Santa Fe – Fantasy Scheme

- Union Pacific – Fantasy Scheme

The Model

The made in Vietnam ready-to-run covered hoppers were packed in a thin chipboard box with clear plastic window. A plastic sheet was wrapped around each model to protect the paint job from blemishes and further sandwiched between a two-piece plastic cradle. The model information is neatly labeled on the end of the box for ease to locate when in storage - but these flimsy chipboard boxes offer no integrity and long-term storage solution. No additional parts were found in the boxes. (For simplicity I will focus the rest of my review on the yellow hopper – CGLX 397).

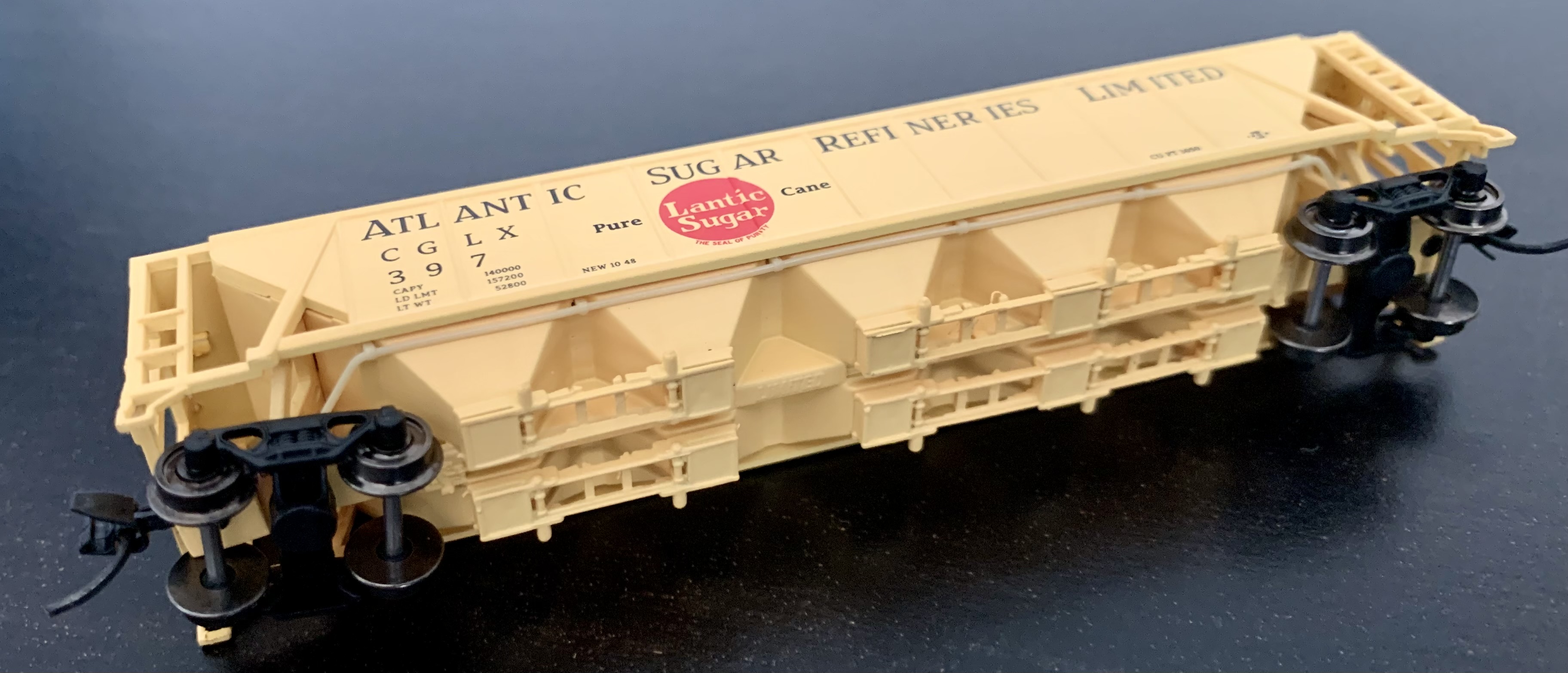

The paint job is neat and even along the entire acrylonitrile butadiene styrene (ABS) body and chassis. The covered hopper is painted a brilliant yellow color with black lettering and the well-known Lantic Sugar ‘Seal of Purity’ red logo. All lettering is clean and sharp. The Atlantic Sugar Refineries Limited H32 hopper is a ‘fantasy’ piece, as no real-life prototype H32 exist in this paint scheme. Yet the choice of colors and fonts – and the placement of characters – are almost identical to the true-life Lantic Sugar 3-bay PS-2 covered hopper series.

The sides of the hopper car feature the H32 prototype correct 12 panel (10 full/2 half) configuration with the distinctive diagonal sloping end support post. Also, the proper two grab iron and full height ladder arrangement near each end is present. Admittedly, the ladder rungs and stirrup steps might be a tad “chunky” for some modelers, but I understand the need for some extra strength for a delicate model of this size. The 3050 cubic-foot hopper is assigned the road marker CGLX (GATX Rail Corp) and stamped within the appropriate H32 timeframe build date of October 1948. Finally, since the H32 hoppers were welded steel railcars – the lack of rivet lines is correct for this model.

Both ends feature a floorless cage with support braces and a full ladder. A factory hand-applied brake wheel and see-thru brake platform are located on the B-End. Brake end appliances include the air tank, air reservoir, brake cylinder, and piping. The road marker and car number are found near top right corner on each end.

The top of the covered hopper has a see-thru Apex Tri-Lok longitudinal running board with two lateral boards. Separately applied grab irons sit upon each lateral. The Apex open design helped to shed water, ice, and snow. Lasty, the welded H32 roof is fitted with fourteen square loading hatches in the correct 6-2-6 pattern.

The underside features an elaborate five-bay/ten-outlet gate arrangement with fine piping and dump handle detail. The BLI model sports the prototype correct 4 and 6 gate cluster grouping. The hopper rides along American Steel Foundry Class 2E-F22A trucks with blackened metal wheels. The model is equipped with body-mounted operating knuckle couplers that were measured to the correct height.

The Broadway Limited Imports H32 model is 3 3/4 inches long and weighs 0.70 ounces, which is somewhat light according to the National Model Railroad Association (NMRA) recommendation of 1.09 ounces. Despite the weight issue, I found it a fluid runner while testing the car on Kato Unitrack with no issues around curves or through turnouts at slow and medium speeds. The suggested minimum operating radius is 9 inches on Code 55, 70 and 80 rails.

Conclusions

In conclusion, I am rather pleased with this oft neglected railcar – to date, Broadway Limited Imports is the only company to have distributed the H32 covered hopper in the N Scale format. I also appreciate when offbeat ‘Fantasy’ paint schemes are offered…just how many Pennsylvania Railroad or Santa Fe rolling stock does one need?!? The vibrant yellow Lantic Sugar hopper sure is an eye-catcher when roaming around my track.The Broadway Limited Imports model appears to be prototypical accurate – with great attention to details and the inclusion of many separately applied parts. It does have its flaws with many modelers commenting about the over thicknesses of the stirrups, ladders, and cage support posts…and the model is under ideal running weight. Myself, I can overlook the added durability to detail parts to prevent bending or breakage. Solid paint job, metal wheels, and body-mounted couplers are some other highlights. No adjustment was needed to have both hoppers run smoothly on my layout regardless of the weight issue. These are a nice inclusion to my collection - a well-made product that adds a pinch of uniqueness to my rolling stock assortment.

To see a list of all items in this series, CLICK HERE

Photo Credits

Weighing, Filling and Sewing 100 Lb. Sacks of Sugar. Unknown Photographer. [Between 1910 and 1920] Photograph Retrieved from the Library of Congress. No known restrictionsVachon, John, photographer. Loading freight car with sacks of flour, Minneapolis, Minnesota. United States Minnesota Minneapolis, 1939. Sept. Photograph Series. U.S. Farm Security Administration/Office of War Information. Retrieved from the Library of Congress. No known restrictions.