Athearn Trains 2600 Airslide Hopper

Published: 2024-01-01 - By: CNW400

Last updated on: 2024-01-03

Last updated on: 2024-01-03

visibility: Public - Headline

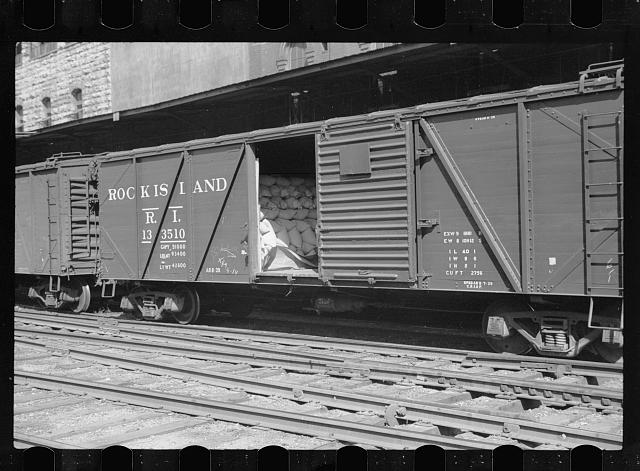

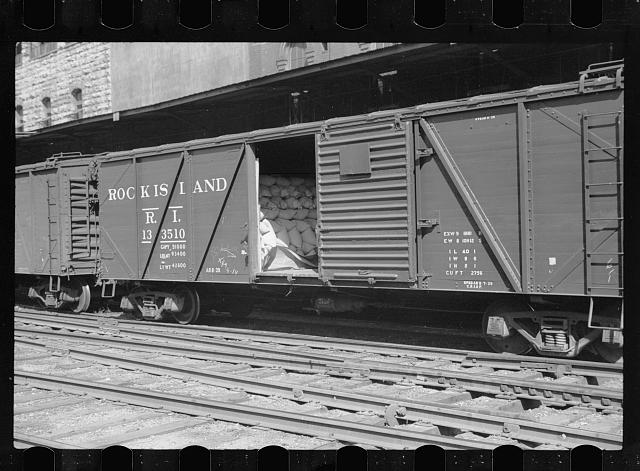

Open hoppers were a prevalent freight car since the 1800’s, used to carry products that did not need protection from the wind and rain such as coal and stone. The railroads were simultaneously looking for a more efficient method of shipping consumer bulk dry goods that were commonly bagged into 100-pound sacks and loaded by hand into standard 40-foot, 50-ton boxcars (1,000 sacks per car). This routine had proved inefficient as it was time-consuming, and a great deal of product was either damaged or contaminated. Boxcars were lined with paper to seal-out rodents, bugs, and moisture and to protect the cloth sacks from nail or wood splinter rips. Beginning around the Turn of the Twentieth Century, flour and sugar were also hauled inside 196-pound wooden barrels.

The railroad industry began to experiment with converting open hoppers by adding a waterproof top and outlet gates on the bottom. The car manufacturers saw an opportunity and met this demand by introducing the first purpose-built covered hoppers to streamline the process of shipping such goods as: flour, sugar, starch, plastic, feed, and fertilizer.

By the mid-1930’s covered hoppers were delivered by railcar manufacturers. These were mostly two-bay, 50 or 70-ton hoppers designed to transport cement and carbon black as well as lime, sand, and phosphate. The covered hopper simplified the hauling process by allowing the commodity to be filled through round or square topside roof hatches and discharged out bottom hopper gates. Fine powdered and granulated products such as flour, sugar, and starch had difficulty flowing and fully discharging from a standard hopper. The Fuller Company hoped to resolve this problem with their Airslide unloading concept. Fuller patented the Airslide design in 1953, the same time Pullman-Standard released their PS-2 covered hoppers.

The Fuller Company’s Airslide conception introduced air pressure to dry bulk materials – modifying its arrangement and making it flow like a liquid through a process called fluidization. During fluidization, a gas is introduced to a fine granular material and removes/displaces friction – converting it from a static state into a fluid state. The Airslide design had a lower chamber lined with a ¼' permeable fabric. Air is pumped into the chamber at a low pressure and flows throughout the powdered product causing it to behave like a liquid and flow outward more smoothly. With fluidization, flow is achieved at an incline of only 8° - unlike the 45+ degrees dry bulk materials need to establish gravity flow and empty out of a standard hopper car.

The General American Transportation Corporation (GATC) realized the enormous potential of the Airslide system and acquired the Fuller Company in 1954 and introduced the GATC 2600-cubic foot Airslide Covered Hopper that same year. This single-bay, 70-ton capacity railcar became the most fashionable way to haul fine dry bulk materials with over 5,000 built from 1954 to 1969. General American Transportation Corporation was later renamed GATX Rail Corporation in 2000.

The initial Airslide hoppers were constructed with open end platforms with support framework. According to GATC blueprints, the hopper was 38’-6” in length along the end sills with a 40’-2” running board, 14’-4” tall, and traveled on 36” diameter wheels. Rectangular car shaker brackets were mounted on the third panel from each end. During the warm, humid summer months it was common to find dry bulk goods ‘caked up’ inside the hopper car. The hopper would be attached to a vibrator machine onto these brackets to help loosen the clumps of material. I read that a few whacks from a sledgehammer would also do the trick – leaving behind scars and dents from the crew’s handiwork. Ideally the hopper cars were unloaded pneumatically with a hose connected to an outlet pipe and another hose connected to an air inlet pipe with air pressure applied to force dry material out.

In 1965, triangular gussets were added to the design atop the open platform ends – adding strength and giving a more conventional hooper car appearance. The covered hopper was loaded via round or square roof hatches. The individual hatches were secured tight with tamper-proof seals after lading. The Airslide hopper was seen as a specialty railcar and most cars were assigned to dedicated shipping points to not contaminate or mix dry goods – especially food items. The hoppers ran with railroad owned road markings or often carried the logos of GATC lessees.

Soon larger load capacity and longer Airslide covered hoppers without end platforms were offered – the GATC two-bay 4180-cubic foot car was introduced in 1963 and supplied 100-ton capacity. At times to extend the usefulness of the smaller 2600-cubic foot cars, two Airslide hoppers were permanently linked with a drawbar and operated as a single car --- offering 5,200-cubic feet of total load capacity. Disadvantages of this configuration included the massive length of this pair and cumbersome arrangement of these attached cars. General American built the Airslide hoppers until 1984 with the trend away from the Airslide discharge system and a movement towards pressure-differential cars.

Primed for Grime cars are made to resemble “In Service” railcars complete with fading and patches. Ready for the modeler to add his/her own personal weathering touches.

Individual cars were available with a suggested retail price of $37.99. The GACX set had a price tag of $62.99 and $72.99 for the Santa Fe primed collection.

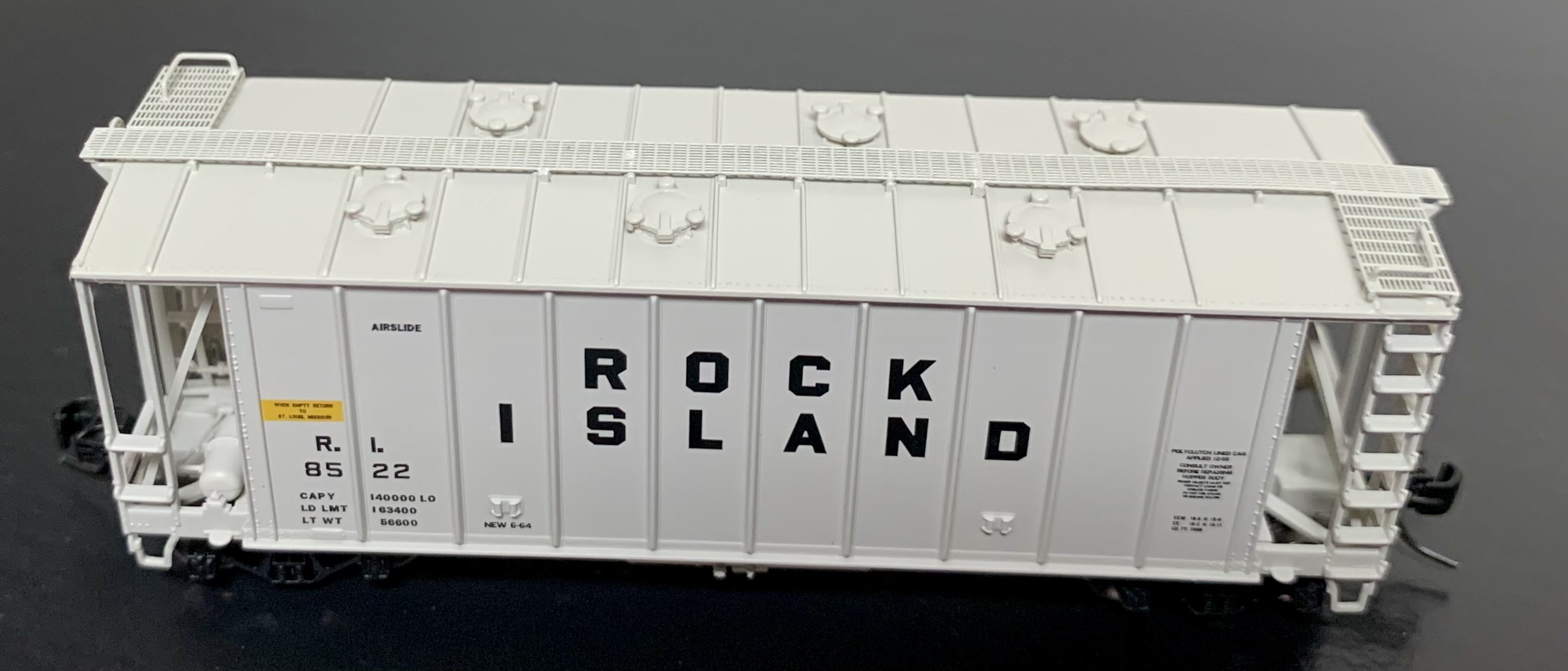

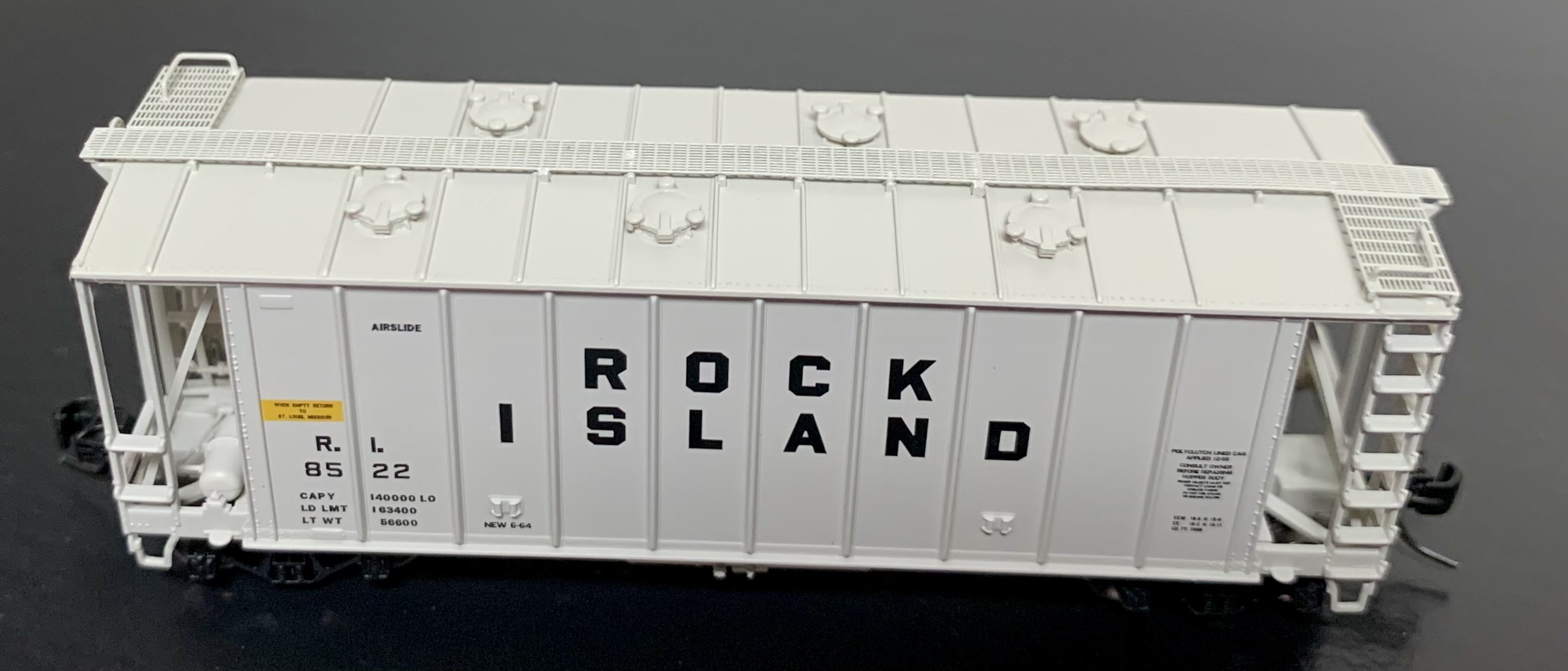

My review includes observations of Athearn Trains stock number: ATH23882 – Rock Island (RI) #8522.

The injection molded plastic model is neatly painted a light grey color with crisp black lettering. All characters are neat, legible, and in the proper arrangement when compared to prototype images. The sides of the Athearn Airslide hopper display the correct ten full panel – nine exterior post configurations found on GATC cars. Molded rectangular car shaker brackets are positioned on the third panel from each end of the hopper. Finally, the Rock Island model with a Built Date of 6-64 displays the era appropriate square open-end platform WITHOUT the angled gusset plates which were introduced in 1965.

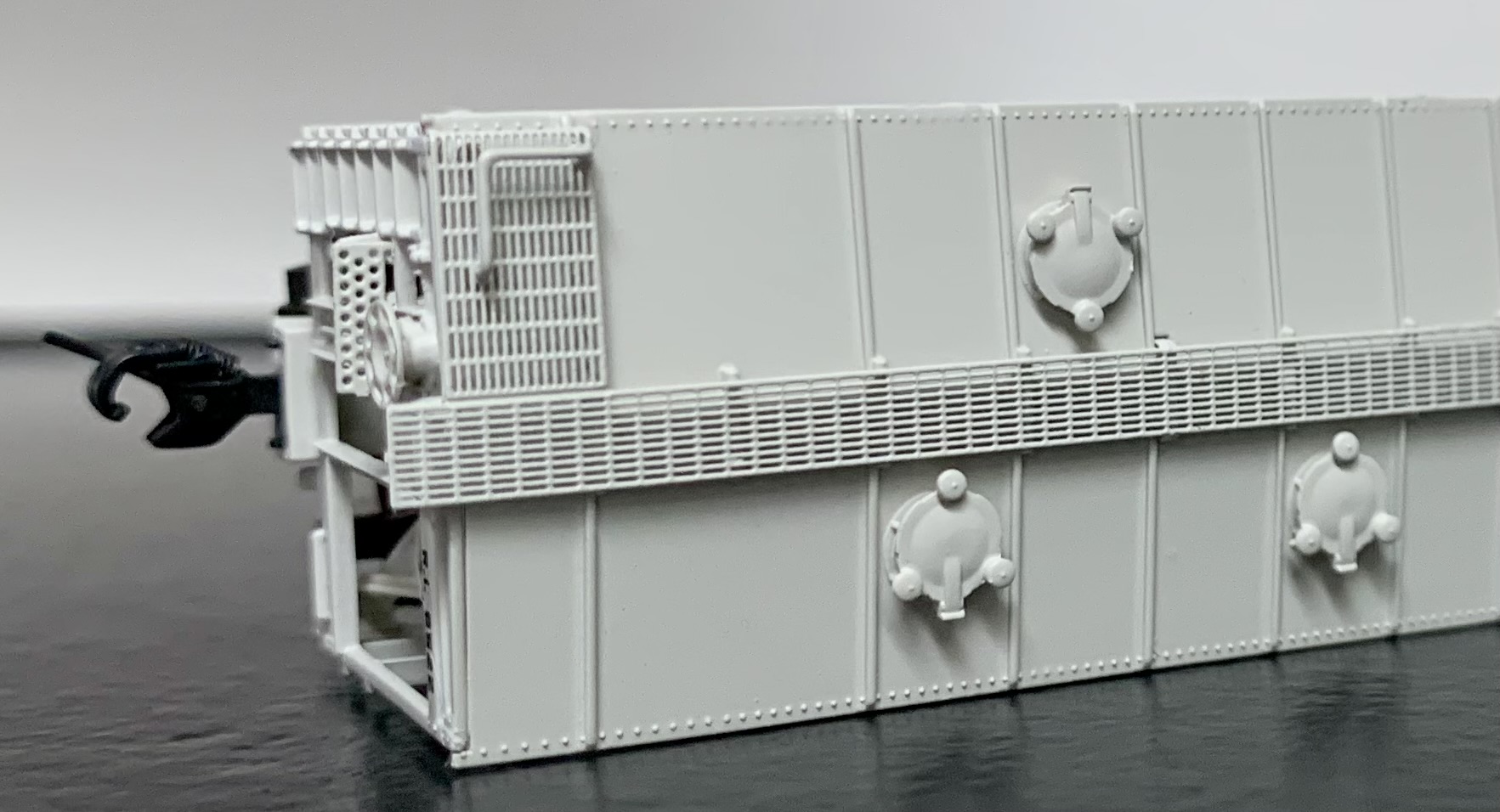

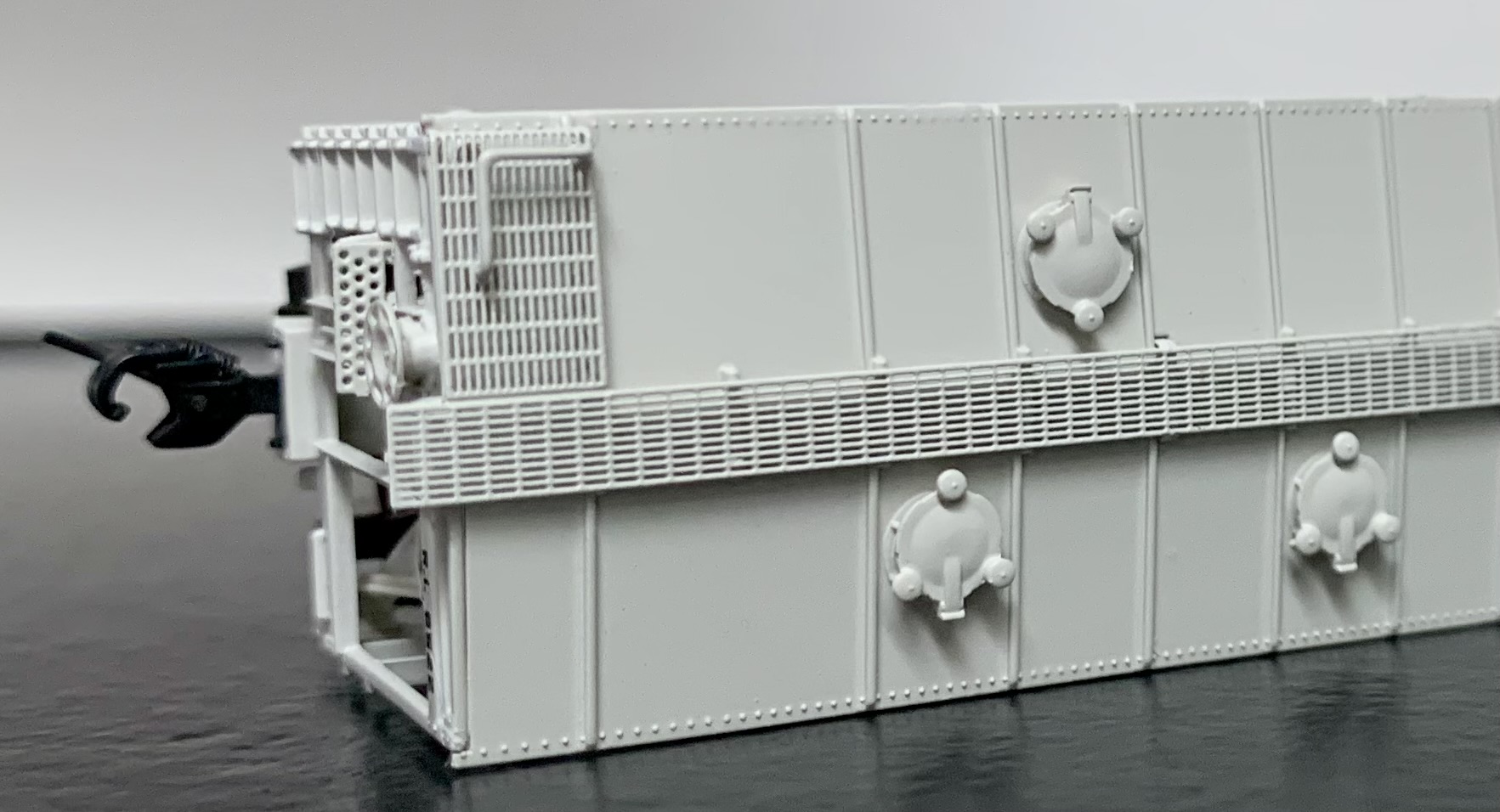

Disappointing are the uneven rivet points along the perimeter of the hopper car along the edge where the end panels and platforms meet – rivets are in a random pattern, and many are flattened and dull. Both open platform ends feature a full-length ladder with vertical and diagonal support rails. The B-end has a separately applied Ajax brake wheel and metal etched brake platform. The platform is patterned after the Morton Manufacturing Company line of treaded safety steel plates – easily recognized from the oval holes punched into the sheets. The air tank, air reservoir, and brake cylinder are also visible and nicely modeled on the brake end. The lettering is neat and in proper arrangement with the road marker & road number at the top right corner of each end.

The top of the hopper has a nicely detailed see-through metal etched running board with end latitudinals and wire grab irons. Also exhibited atop are six separately applied round roof hatches for loading. Unfortunately, more dull rivet points are visible along the outskirts of the roof.

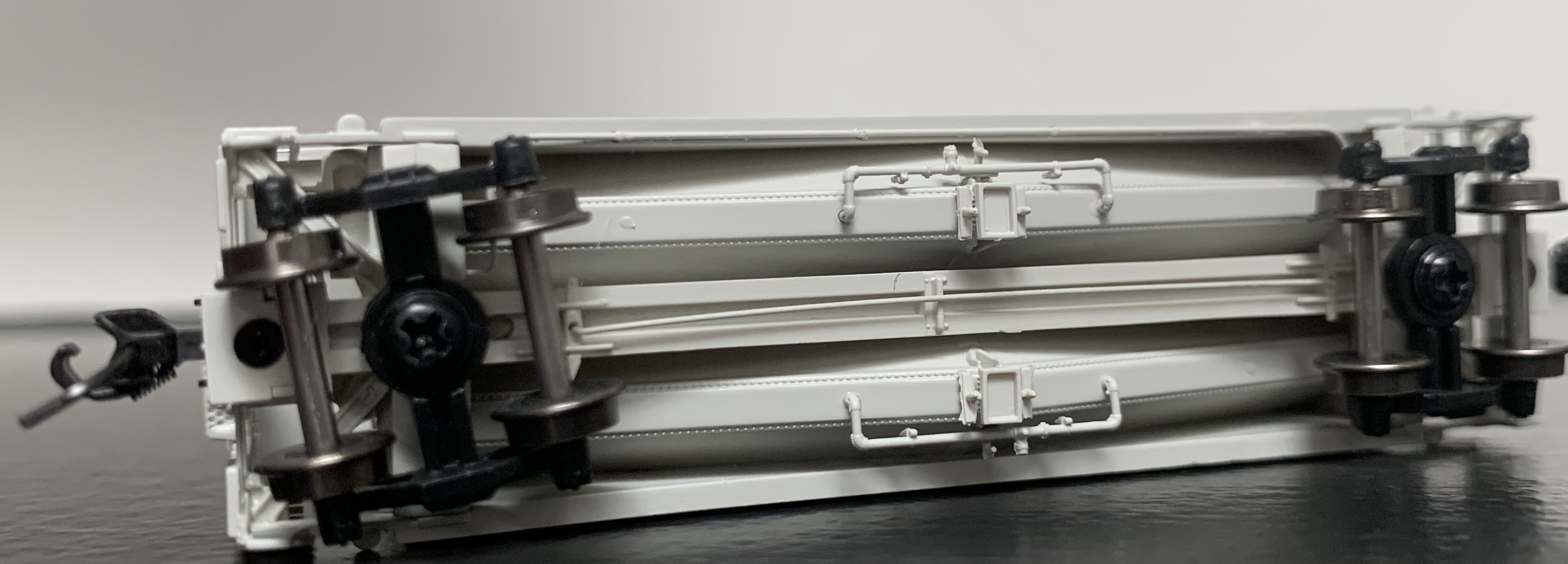

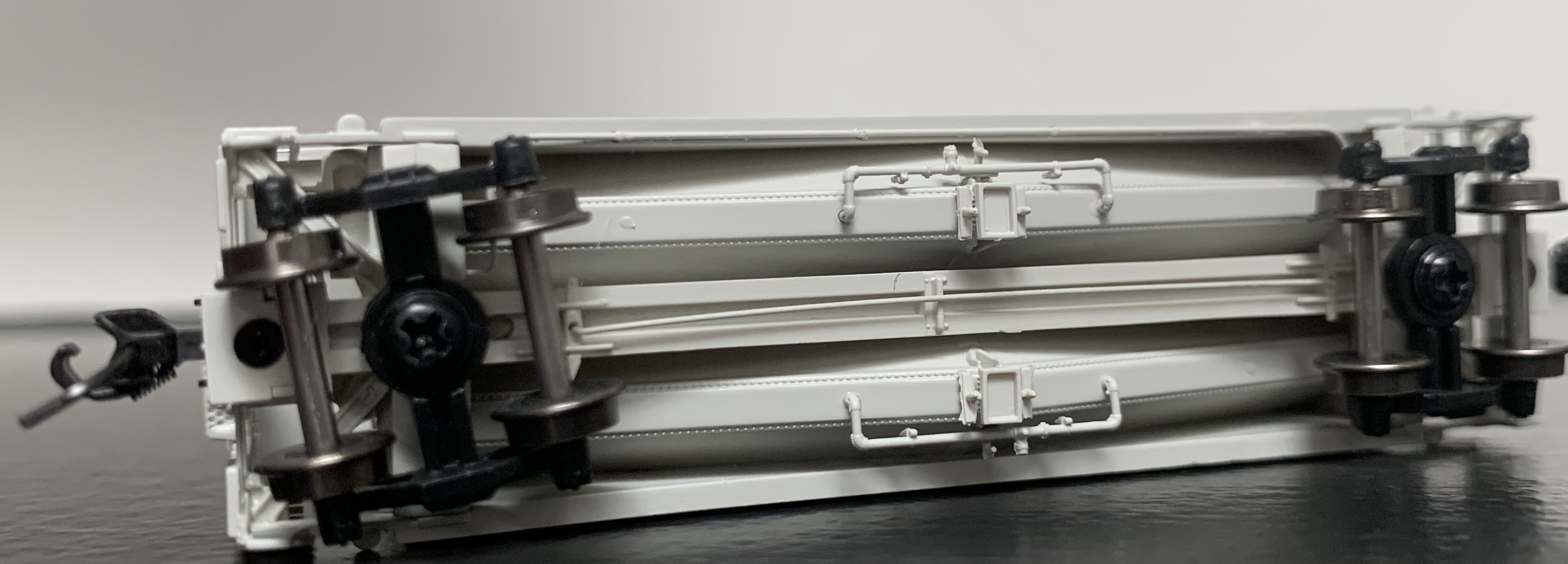

The underframe has a highly detailed gravity-pneumatic outlet gate arrangement with piping and brake line features. The Airslide hopper rides along prototype specific Bettendorf or Roller Bearing trucks with blackened metal wheels. The model is equipped with body-mounted McHenry operating scale knuckle couplers – both were set to the correct operating height with no difficulty connecting to other brand couplers.

The car measures 3 inches in length and weighs exactly 1.0 ounce, which is about perfect according to the National Model Railroad Association (NMRA) recommendations of 0.97 ounces for a model of this size. Athearn Trains added weight to this car for optimal tracking performance. The hopper car has a nice hefty feeling in hand. I found it a fine runner while testing the car on Kato Unitrack with no issues around curves or through turnouts at both slow and medium speeds. The recommended minimum operating radius is 9 ¾".

Another admirable release from Athearn Trains – prototypical correct model with many separately applied details parts and upgrades most hobbyists appreciate and expect these days such as metal wheels and body-mounted couplers. The only negative would be the inconsistent rivet lines – while only noticed by the more observant collector, they are still a blemish for an otherwise notable railcar series. An excellent running Airslide covered hopper that needs no adjustment to travel smoothly. I am not full of hot air when I say to slide on down to your favorite hobby shop and grab yourself a pair of Athearn N Scale 2600cf Airslide Hoppers.

To see a list of all cars in this series, CLICK HERE

• Vachon, J., photographer. (1939) Freight cars loaded with sacks of flour, Pillsbury mills, Minneapolis, Minnesota. United States Minnesota Minneapolis, 1939. Sept. [Photograph] Retrieved from the Library of Congress, https://www.loc.gov/item/2017718316/.

The railroad industry began to experiment with converting open hoppers by adding a waterproof top and outlet gates on the bottom. The car manufacturers saw an opportunity and met this demand by introducing the first purpose-built covered hoppers to streamline the process of shipping such goods as: flour, sugar, starch, plastic, feed, and fertilizer.

By the mid-1930’s covered hoppers were delivered by railcar manufacturers. These were mostly two-bay, 50 or 70-ton hoppers designed to transport cement and carbon black as well as lime, sand, and phosphate. The covered hopper simplified the hauling process by allowing the commodity to be filled through round or square topside roof hatches and discharged out bottom hopper gates. Fine powdered and granulated products such as flour, sugar, and starch had difficulty flowing and fully discharging from a standard hopper. The Fuller Company hoped to resolve this problem with their Airslide unloading concept. Fuller patented the Airslide design in 1953, the same time Pullman-Standard released their PS-2 covered hoppers.

The Fuller Company’s Airslide conception introduced air pressure to dry bulk materials – modifying its arrangement and making it flow like a liquid through a process called fluidization. During fluidization, a gas is introduced to a fine granular material and removes/displaces friction – converting it from a static state into a fluid state. The Airslide design had a lower chamber lined with a ¼' permeable fabric. Air is pumped into the chamber at a low pressure and flows throughout the powdered product causing it to behave like a liquid and flow outward more smoothly. With fluidization, flow is achieved at an incline of only 8° - unlike the 45+ degrees dry bulk materials need to establish gravity flow and empty out of a standard hopper car.

The General American Transportation Corporation (GATC) realized the enormous potential of the Airslide system and acquired the Fuller Company in 1954 and introduced the GATC 2600-cubic foot Airslide Covered Hopper that same year. This single-bay, 70-ton capacity railcar became the most fashionable way to haul fine dry bulk materials with over 5,000 built from 1954 to 1969. General American Transportation Corporation was later renamed GATX Rail Corporation in 2000.

The initial Airslide hoppers were constructed with open end platforms with support framework. According to GATC blueprints, the hopper was 38’-6” in length along the end sills with a 40’-2” running board, 14’-4” tall, and traveled on 36” diameter wheels. Rectangular car shaker brackets were mounted on the third panel from each end. During the warm, humid summer months it was common to find dry bulk goods ‘caked up’ inside the hopper car. The hopper would be attached to a vibrator machine onto these brackets to help loosen the clumps of material. I read that a few whacks from a sledgehammer would also do the trick – leaving behind scars and dents from the crew’s handiwork. Ideally the hopper cars were unloaded pneumatically with a hose connected to an outlet pipe and another hose connected to an air inlet pipe with air pressure applied to force dry material out.

In 1965, triangular gussets were added to the design atop the open platform ends – adding strength and giving a more conventional hooper car appearance. The covered hopper was loaded via round or square roof hatches. The individual hatches were secured tight with tamper-proof seals after lading. The Airslide hopper was seen as a specialty railcar and most cars were assigned to dedicated shipping points to not contaminate or mix dry goods – especially food items. The hoppers ran with railroad owned road markings or often carried the logos of GATC lessees.

Soon larger load capacity and longer Airslide covered hoppers without end platforms were offered – the GATC two-bay 4180-cubic foot car was introduced in 1963 and supplied 100-ton capacity. At times to extend the usefulness of the smaller 2600-cubic foot cars, two Airslide hoppers were permanently linked with a drawbar and operated as a single car --- offering 5,200-cubic feet of total load capacity. Disadvantages of this configuration included the massive length of this pair and cumbersome arrangement of these attached cars. General American built the Airslide hoppers until 1984 with the trend away from the Airslide discharge system and a movement towards pressure-differential cars.

Road Names and Pricing

Announced in October 2021, Athearn Trains most recent collection of 2600cf Airslide Covered Hoppers was released in November 2022 and included six schemes:- Frisco

- GACX

- Rock Island

- Santa Fe

- Seaboard Coast Line

- Southern Pacific

Primed for Grime cars are made to resemble “In Service” railcars complete with fading and patches. Ready for the modeler to add his/her own personal weathering touches.

Individual cars were available with a suggested retail price of $37.99. The GACX set had a price tag of $62.99 and $72.99 for the Santa Fe primed collection.

My review includes observations of Athearn Trains stock number: ATH23882 – Rock Island (RI) #8522.

The Model

The ready-to-run covered hopper came packaged in a clear plastic jewel case with a slip-off cover and a two-piece plastic cradle to support the model. The jewel case was found nestled inside a white chipboard sleeve. The model information is clearly labeled on the end of the case for ease to locate when in storage. A thin plastic film was also wrapped around the car to protect the railcar from scuffmarks. No additional parts were found in the case.

The injection molded plastic model is neatly painted a light grey color with crisp black lettering. All characters are neat, legible, and in the proper arrangement when compared to prototype images. The sides of the Athearn Airslide hopper display the correct ten full panel – nine exterior post configurations found on GATC cars. Molded rectangular car shaker brackets are positioned on the third panel from each end of the hopper. Finally, the Rock Island model with a Built Date of 6-64 displays the era appropriate square open-end platform WITHOUT the angled gusset plates which were introduced in 1965.

Disappointing are the uneven rivet points along the perimeter of the hopper car along the edge where the end panels and platforms meet – rivets are in a random pattern, and many are flattened and dull. Both open platform ends feature a full-length ladder with vertical and diagonal support rails. The B-end has a separately applied Ajax brake wheel and metal etched brake platform. The platform is patterned after the Morton Manufacturing Company line of treaded safety steel plates – easily recognized from the oval holes punched into the sheets. The air tank, air reservoir, and brake cylinder are also visible and nicely modeled on the brake end. The lettering is neat and in proper arrangement with the road marker & road number at the top right corner of each end.

The top of the hopper has a nicely detailed see-through metal etched running board with end latitudinals and wire grab irons. Also exhibited atop are six separately applied round roof hatches for loading. Unfortunately, more dull rivet points are visible along the outskirts of the roof.

The underframe has a highly detailed gravity-pneumatic outlet gate arrangement with piping and brake line features. The Airslide hopper rides along prototype specific Bettendorf or Roller Bearing trucks with blackened metal wheels. The model is equipped with body-mounted McHenry operating scale knuckle couplers – both were set to the correct operating height with no difficulty connecting to other brand couplers.

The car measures 3 inches in length and weighs exactly 1.0 ounce, which is about perfect according to the National Model Railroad Association (NMRA) recommendations of 0.97 ounces for a model of this size. Athearn Trains added weight to this car for optimal tracking performance. The hopper car has a nice hefty feeling in hand. I found it a fine runner while testing the car on Kato Unitrack with no issues around curves or through turnouts at both slow and medium speeds. The recommended minimum operating radius is 9 ¾".

Another admirable release from Athearn Trains – prototypical correct model with many separately applied details parts and upgrades most hobbyists appreciate and expect these days such as metal wheels and body-mounted couplers. The only negative would be the inconsistent rivet lines – while only noticed by the more observant collector, they are still a blemish for an otherwise notable railcar series. An excellent running Airslide covered hopper that needs no adjustment to travel smoothly. I am not full of hot air when I say to slide on down to your favorite hobby shop and grab yourself a pair of Athearn N Scale 2600cf Airslide Hoppers.

To see a list of all cars in this series, CLICK HERE

Photo Credits

• Vachon, J., photographer. (1939) Flour mills and railroad cars, Minneapolis, Minnesota. United States Minnesota Minneapolis, 1939. Sept. [Photograph] Retrieved from the Library of Congress, https://www.loc.gov/item/2017719026/.• Vachon, J., photographer. (1939) Freight cars loaded with sacks of flour, Pillsbury mills, Minneapolis, Minnesota. United States Minnesota Minneapolis, 1939. Sept. [Photograph] Retrieved from the Library of Congress, https://www.loc.gov/item/2017718316/.