Rapido Trains AutoFlood III Coal Hopper

Published: 2023-08-30 - By: CNW400

Last updated on: 2023-08-30

Last updated on: 2023-08-30

visibility: Public - Headline

The Prototype

During the 1890s, the open hopper and gondola were among the first all steel freight cars constructed for the railroads to combat the abuse and damage they suffered while placed into service hauling coal and other aggregates (gravel, stone, etc.) from mines to industrial centers and shipping ports. During this era – the railroad was king...the primary means to transport passengers and haul goods within our expanding nation.Fast forward to the 1960s – the railroad industry was experiencing a decrease in most categories of traffic except coal and ore. We all know the stories of railroads losing passenger service to automobiles and improved highway systems. And the trucking industry gaining business because of those same roadways and the rate hike restrictions placed on rail service, along with worsening labor strife. According to the Association of American Railroads (AAR), five states account for over 70% of American coal production. That is still true in 2022, 3.4 million loads of coal were hauled in the United States to power plants to produce electricity, mills & industrial shops, and ports to be exported overseas.

Robert Ortner, president of the Ortner Freight Car Company from 1953 to 1982, had the foresight in the early 1960s to ensure the rail system held their grip on the coal trade with advancements in equipment and service. Ortner developed the rapid-discharge door system (RDL)...a 5-bay hopper with air-activated bottom outlet gates that unload a 100-ton car within 30 seconds. There was no longer the need for manual labor to open hatches by hand and a coal unit train could be fully emptied within an hour. Trinity Industries acquired Ortner Freight Car in 1986 and still manufactures aluminum hoppers with rapid-discharge technology.

In the Fall of 1991, TMB Industries Investment Group purchased Bethlehem Steel’s freight car division for $50 million. Renamed Johnstown America Industries, the newly founded company concentrated on coal car production and expanded into heavy-duty truck parts, iron castings, and intermodal freight cars. There are a few common means to transport coal by railcar: Manual door operated cross-hopper cars. Or 4/5-bay, 100-ton coal cars with gravity bottom gates that are opened and closed by hand. The Bethlehem Johnstown 100-ton cross-hopper is a favored design for this type of car.

The rotary-dump gondola (bathtub gondola) is emptied by overturning into a rotary dumper. This is a much slower process with each car situated individually in the rotary dumper. Modern aluminum body versions have replaced older all-steel cars. Aluminum is much softer and lighter than steel, thus only ideal for hauling coal. A disadvantage of this type of car is that it is designed to only be unloaded with a rotary dumping system. If that system fails or breaks-down it can be emptied with an excavator – very time-consuming...and time is money.

Rapid-discharge hoppers with air-actuated gates on each side of the bay. An air cylinder unlocks and opens all bottom doors with an electrical signal received from a third rail pickup shoe. When a car is positioned over a dumping pit – the railcar contacts a pickup shoe that sends a 27-volt signal to the spool valve. The spool valve then sends air to the drive cylinder. Once the cylinder extends fully, it activates the main opening lever. The entire car empties within 20-30 seconds. These cars offer the versatility of both rapid bottom discharge and rotary unloading depending on the facility. Again, modern cars have aluminum bodies.

The AutoFlood was Johnstown America’s entry in the rapid-discharge hopper market. The all-aluminum AutoFlood II was released in 1996 and our subject railcar, the AutoFlood III, began production in 2004. Both models are equipped with the MegaFloTM door system. That same year of 2004 - Johnstown America change their name to FreightCar America. Although still headquartered in Chicago and links to American railcar building as early as 1901, all FreightCar America’s new production is now carried out in Mexico with a parts plant in Pennsylvania.

The 4300 cubic foot, exterior post AutoFlood III has an aluminum body – it weighs a relatively light 49,400 pounds with a coal load capacity of 236,600 pounds (286,000 gross rail load). The 5-bay open-hopper is furnished with three double-door pockets in the middle and single-door pockets on each end. The interior is smooth with steep end slopes. The contents can be emptied with the auto-discharge system via the bottom gates or rotary dumped. The color end panel signifies which end of the car is fitted with a rotary coupler. The rotary coupler is located on the A end of the car (both ends for a double rotary car) and permits a unit train to be unloaded without being uncoupled...importantly - the arrangement of the rotary coupler end must remain constant throughout the entire train to accomplish this feat (example – all colored panels on the left when facing the train from a side profile).

The AutoFlood III is 50’-5 ½" long (striker to striker) and 13’4” in height.

The Association of American Railroads (AAR) mechanical designation for the AutoFlood III hopper is HTS / Type K: (HT) “An Open Top Self-Clearing Car, having fixed sides and ends and bottom consisting of three or more divided hoppers with doors hinged crosswise of car and dumping between rails. Where cars are equipped with permanent racks for stowing parts or are specially modified or equipped to provide for loading of a particular commodity, the letter "S" should be affixed to the applicable designating letters.” Type K for an equipped hopper car. (Source: AAR Mechanical Designation Guide) The AAR further identifies hoppers by body construction: outside braced/exterior post or offset with a smooth exterior and inside posts – steel or aluminum – welded or riveted...also the number of bays and load capacity.

Road Names and Pricing

In December 2022, Rapido Trains released the Johnstown America AutoFlood III hopper – the first time ever made available to the N-Scale community. Rapido claims to have studied manufacturer drawings and conducted field measurements to supply the most detailed and realistic model possible for the N-Scale hobby. The road names released for this introductory series include:- Burlington Northern Santa Fe (BNSF Wedge)

- Burlington Northern Santa Fe (BNSF Wedge – Double Rotary)

- Carolina Power & Light Company (PGNX)

- CIT Group/Capital Finance Lease (CEFX – Indiana Railroad)

- CIT Group/Capital Finance Lease (CEFX – Indiana Railroad - 2,000,000th Carload)

- GATX Corp. (GGPX)

- Gulf Power Company (GLFX)

- Union Pacific (CMO)

- Westar Energy (KPLX)

The Model

The coal hopper arrived in a rigid oversized clear plastic jewel case with a slip-off cover and two-piece plastic cradle to cushion the model. A thin plastic sheet was wrapped around the car to protect it from blemishes during shipping. The model information is clearly labeled on the end for ease to locate when in storage. A seven-inch long magnetic ‘Magic Wand,’ to assist in removing the supplied coal load, is also included in the case. A single page information sheet was found hiding underneath the white plastic cradle.

The sides are neatly and evenly painted in a metallic silver (aluminum) color with black lettering. All lettering and data panels are sharp and in the proper locations when compared to the prototype image of CEFX 600600. The Rapido Trains model exhibits the correct 13-post pattern. Rivet lines are crisp and show the interior end slope angle. The safety instructions and information decals are legible and highly accurate...including reflective yellow conspicuity stripes and warning labels to use only radiant heat with a maximum temperature of 250° F to thaw frozen clumps of coal – else risk damage to the soft metal aluminum body.

The A-End of the hopper has labels and red painted panels denoting that it is the rotary coupler end. The road marker and road number are also shown in the upper right corner. The plastic end cage features a ladder, bracing, and a separately applied cross-over platform and coupler cut bar. Interior A-End cage details include the MegaFlo drive cylinder and air drive cylinder.

The B-End (brake end) is the same metallic silver color as the car body – signifying that it is a single rotary coupler car. This end has the same basic design as the A-End with the inclusion of a brake wheel with detailed chain assembly and braking components (air reservoir and brake cylinder) inside the cage.

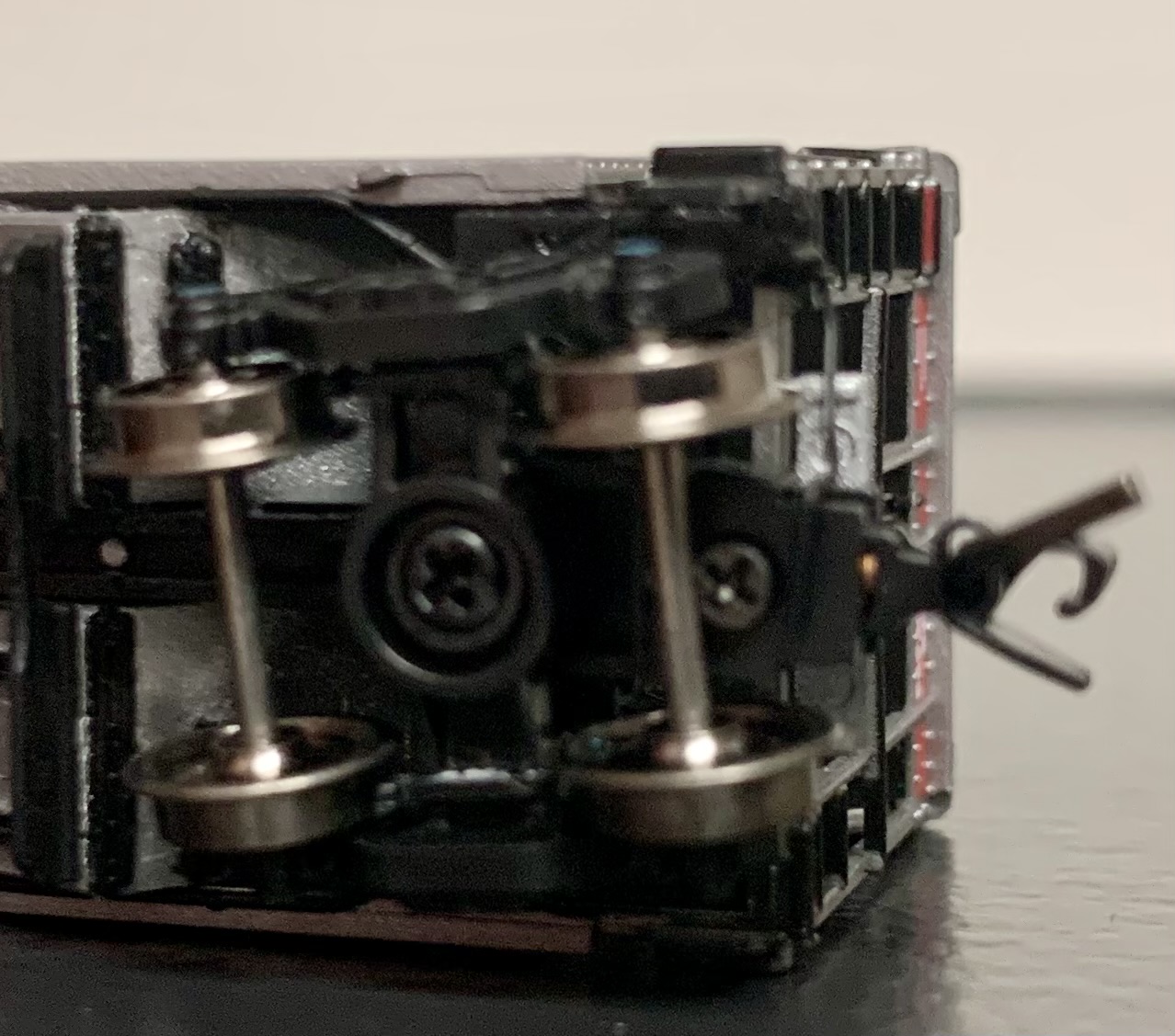

The underside displays the 5-bay discharging gates with the correct double-door configuration for the three middle bays and single door for the two end gates. Separately applied door stiffener ribs are also affixed. The coal hopper rides along Barber S-2 100-ton trucks with 36” low profile blackened metal wheels and blue bearing caps. Both screw body-mounted couplers measured to the correct height. The recommended minimum operating radius is 9 3⁄4" for both Code 55 and 80 rails.

The AutoFlood III interior features sharp rivet detail and die-cast floor for optimal weight and car balance. The model has prototype correct flat sides and steep end slopes to maximize load capacity and speed of discharge. Other model elements include corner post braces (black corner pieces visible from top), K-Member braces (V-shape braces in center) and discharge gate details.

The supplied removable plastic coal load is your typical shiny black detail piece. A nice ‘add-on’ but still fake-looking. A little scale-sized coal dust applied would give a more realistic appearance and add some weight. The underside of the plastic load has a magnetic piece to work with your ‘Magic Wand’ to easily remove the coal without tipping the hopper or even stopping the train from rolling.

The hopper is 3 ½ inches in length and weighs 1.0 with the supplied coal load (0.90 without), which is just a tad light according to the National Model Railroad Association (NMRA) recommendations of 1.05 for a car of this size. For the most part, I experienced little trouble running the model on Kato Unitrack at low and medium speeds through curves and turnouts. As noted by fellow modelers, I also encountered a slight wheel drag while operating the hopper car. The problem (which is a quick fix) appears to be the mounting screw for the body coupler. The screw was not fully flush, thus creating friction between the screw and axle. A twist or two should solve the issue --- use caution to not overtighten.

Rapido Trains receives high marks for designing an exceptionally accurate and prototypical correct model of the AutoFlood III hopper – one of the workhorses catering the coal industry. Clean metallic paint with neat letters, stencils, and decal work. Sharp rivet points and plenty of separately applied detail parts. The die-cast floor and metal wheels assure smooth-running BUT points are deducted for construction issues concerning the coupler mounting screws...too many modelers have complained of this issue to ignore it. A fine model for those operating the modern coal industry that made need a little tweaking for flawless performance.

To see a list of all cars in this series, CLICK HERE