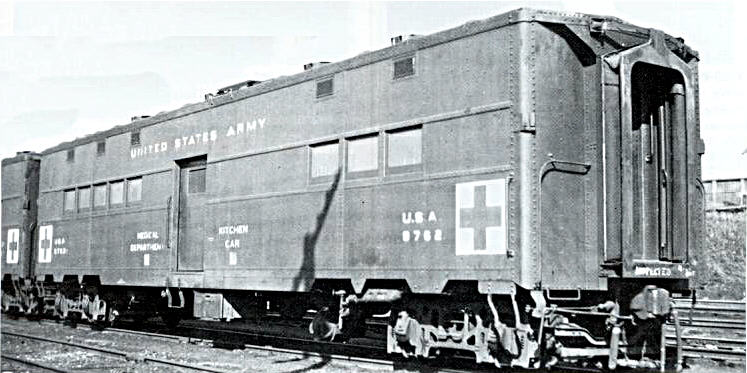

Prototype History: During World War II, the U.S. government relied on America’s extensive railway system to move the millions of enlisted personnel (close to 44 million armed services personnel traveled via U.S. railroads from December 1942 to June 1945) across the country to and from various bases and assignments. This form of transportation was the most practical given the gasoline rationing, the lack of an interstate highway system and only a few readily available passenger air crafts.

Although pragmatic, this mode of transportation did not come without its challenges. In December 1941, when the U.S. entered the war after Japan’s attack on Pearl Harbor, the number of existing standard railway passenger cars was not nearly enough to haul the huge numbers of personnel and materials needed to support the war effort. As a result, the U.S. Office of Defense Transportation (created to ensure that all national transportation priorities were fulfilled), requisitioned the Pullman-Standard Car Manufacturing Company and the American Car & Foundry to build hybrid troop cars.

The Pullman-Standard Car Manufacturing Company produced 2,400 troop sleepers (a mobile barracks) and 10 kitchen cars, while American Car & Foundry built 440 kitchen cars and 200 hospital cars. These trains were vital to the country’s war effort. For instance, in 1944, considered the peak war year, 97% of military passengers traveled by rail.

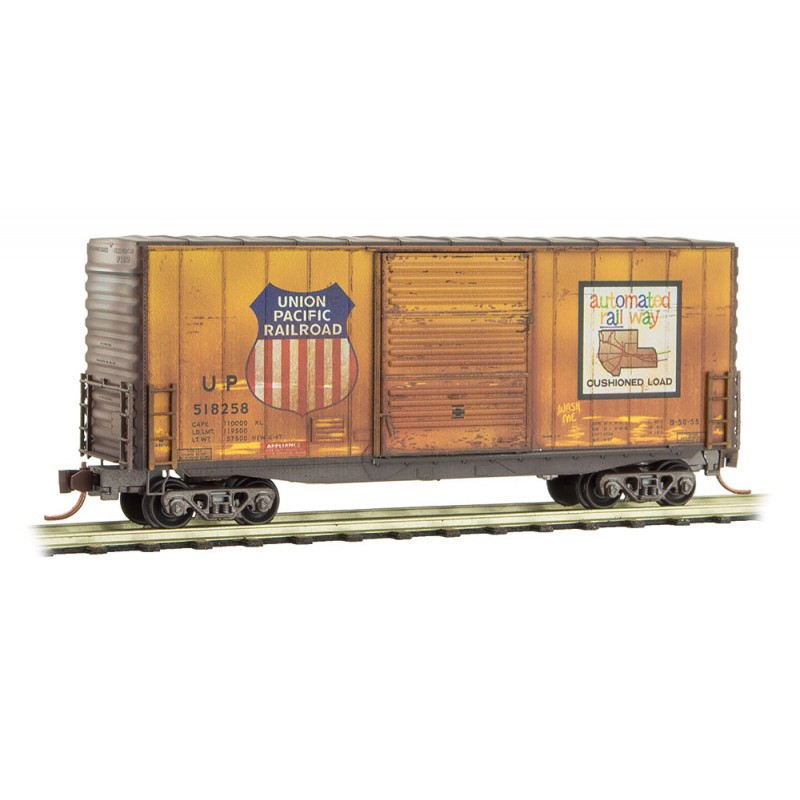

In effort to create as many troop cars as quickly and efficiently as possible, these rolling stock were manufactured based on standard Association of American Railroads 50’ 6” single–sheathed steel boxcars. Made entirely of steel, with heavily reinforced ends, troop cars utilized existing design elements, fixtures, manufacturing lines, materials and production equipment. They featured the following: Allied Full Cushion high-speed swing motion trucks, light-weight passenger car-like flat ends and doors, freight car-like floors, roofs, and sides, a row of windows, and a centered door along each body side.

Troop sleeper cars were painted olive drab with "Pullman" lettered in gold above the center door. Although owned by the government, troop sleepers were managed by Pullman and staffed with company-employed Pullman Porters. Each sleeper could accommodate 29 military personnel (with bunk beds stacked 3-high) and a Pullman porter.

Although pragmatic, this mode of transportation did not come without its challenges. In December 1941, when the U.S. entered the war after Japan’s attack on Pearl Harbor, the number of existing standard railway passenger cars was not nearly enough to haul the huge numbers of personnel and materials needed to support the war effort. As a result, the U.S. Office of Defense Transportation (created to ensure that all national transportation priorities were fulfilled), requisitioned the Pullman-Standard Car Manufacturing Company and the American Car & Foundry to build hybrid troop cars.

The Pullman-Standard Car Manufacturing Company produced 2,400 troop sleepers (a mobile barracks) and 10 kitchen cars, while American Car & Foundry built 440 kitchen cars and 200 hospital cars. These trains were vital to the country’s war effort. For instance, in 1944, considered the peak war year, 97% of military passengers traveled by rail.

In effort to create as many troop cars as quickly and efficiently as possible, these rolling stock were manufactured based on standard Association of American Railroads 50’ 6” single–sheathed steel boxcars. Made entirely of steel, with heavily reinforced ends, troop cars utilized existing design elements, fixtures, manufacturing lines, materials and production equipment. They featured the following: Allied Full Cushion high-speed swing motion trucks, light-weight passenger car-like flat ends and doors, freight car-like floors, roofs, and sides, a row of windows, and a centered door along each body side.

Troop sleeper cars were painted olive drab with "Pullman" lettered in gold above the center door. Although owned by the government, troop sleepers were managed by Pullman and staffed with company-employed Pullman Porters. Each sleeper could accommodate 29 military personnel (with bunk beds stacked 3-high) and a Pullman porter.

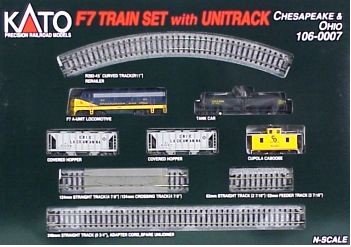

Brand/Importer Information: Micro-Trains is the brand name used by both Kadee Quality Products and Micro-Trains Line. For a history of the relationship between the brand and the two companies, please consult our Micro-Trains Collector's Guide.

Manufacturer Information:  Micro-Trains Line split off from Kadee Quality Products in 1990. Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Micro-Trains Line split off from Kadee Quality Products in 1990. Kadee Quality Products originally got involved in N-Scale by producing a scaled-down version of their successful HO Magne-Matic knuckle coupler system. This coupler was superior to the ubiquitous 'Rapido' style coupler due to two primary factors: superior realistic appearance and the ability to automatically uncouple when stopped over a magnet embedded in a section of track. The success of these couplers in N-Scale quickly translated to the production of trucks, wheels and in 1972 a release of ready-to-run box cars.

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Please consult our Micro-Trains Collector's Guide

Micro-Trains Line Co. split off from Kadee in 1990 to form a completely independent company. For this reason, products from this company can appear with labels from both enterprises. Due to the nature of production idiosyncrasies and various random factors, the rolling stock from Micro-Trains can have all sorts of interesting variations in both their packaging as well as the products themselves. When acquiring an MTL product it is very important to understand these important production variations that can greatly enhance (or decrease) the value of your purchase.

Please consult our Micro-Trains Collector's Guide

Item created by: gdm on 2017-03-23 10:25:10

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.